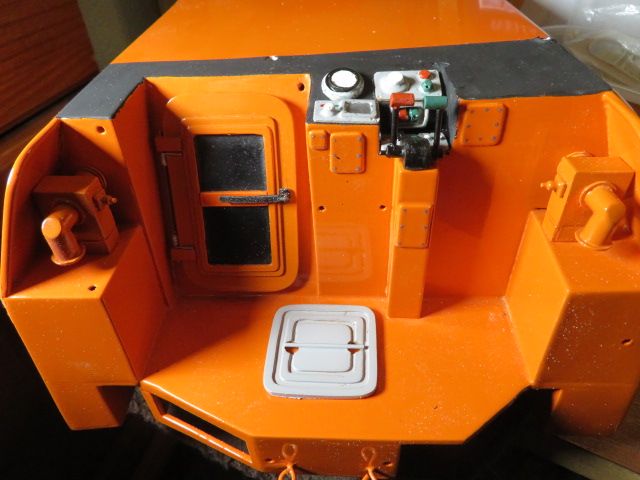

onwards and upwards….

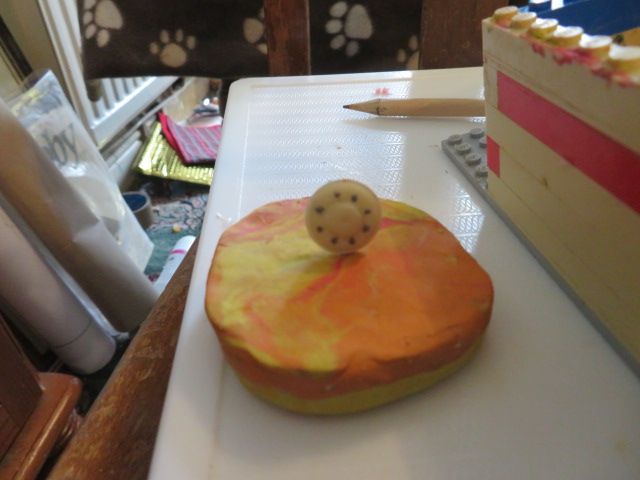

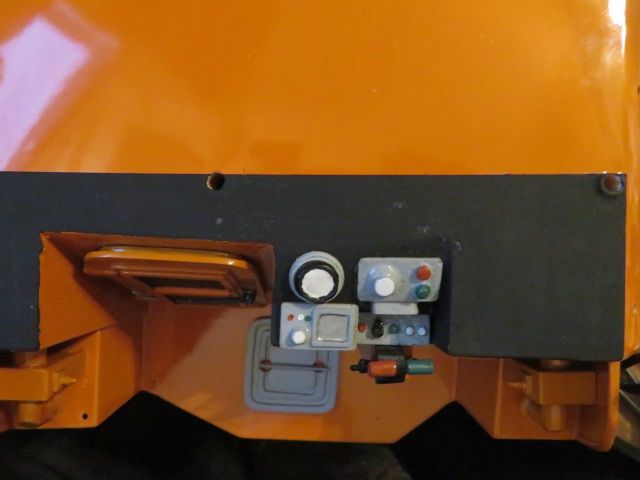

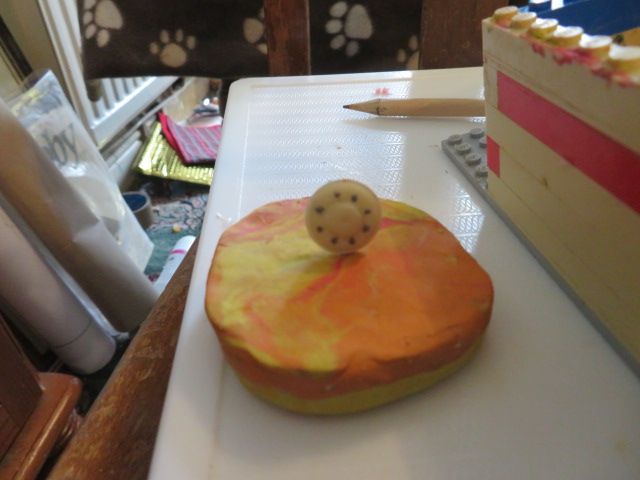

I have now decided not to waste valuable silicon rubber on making a mold for the small foot switch for the Mersey and Tyne capstains, and so just dtilled the fitting from underside, glued in a piece of 1.2mm brass wire and then impress the master into plasticine , I can then mould 5 at time instead of one with all the waste that goes with it.

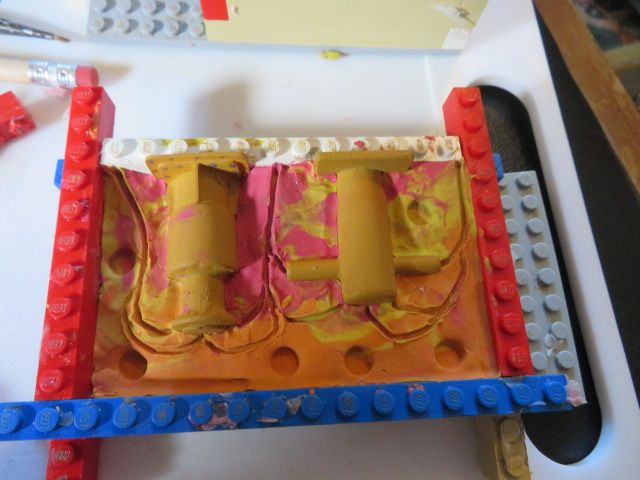

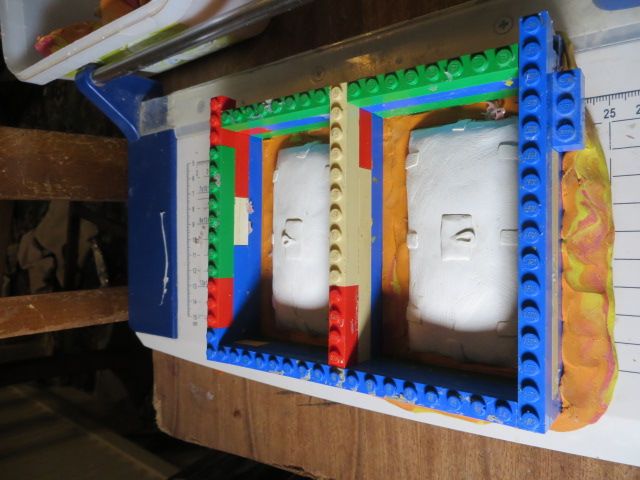

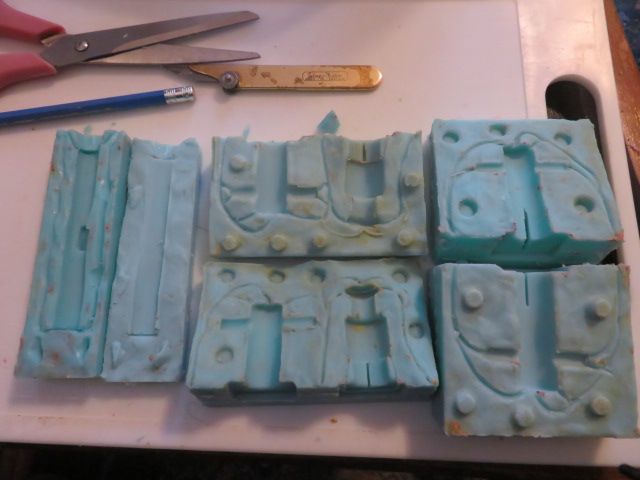

Then it was a case for making the mold boxes for the bow and stern towing/mooring bollards, for Mersey and Tyne and the capstain for the Mersey.

As usual i used my box of Lego for the boxes, and put the base of each item hard up to the wall of the box. with the cross bars lying horizontally to the level of plasticine, thus allowing the mould when split to show the bar easily extractable i encased all 3 masters up to half way around the full perimeter of each master.

i made track marks with a pencil lead in the plasticine to make life easy to trace and cut out for any trapped air as the resin is poured in, and undentations in the mould for corresponding locating pegs once the second half is cast………….

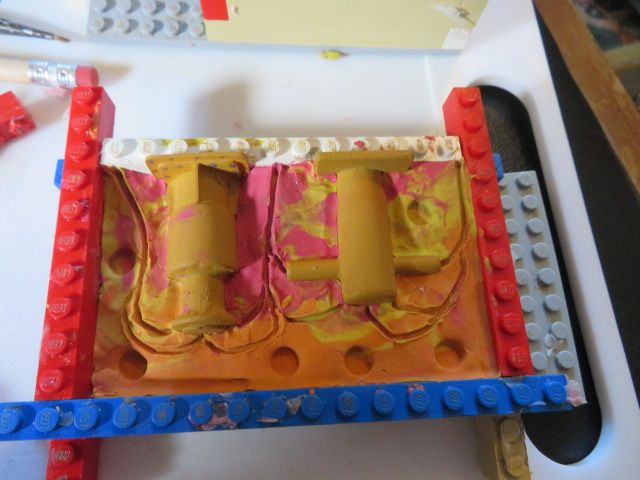

and got down to casting them……however not before putting some risers on the underside of the mold base to raise one side.

the mold will be much thicker at the top of the mold because of the base, and so not to waste rubber where it is not needed, i canted the molds raised so that the rubber running paralel to earth will cover both ends with equal amounts.

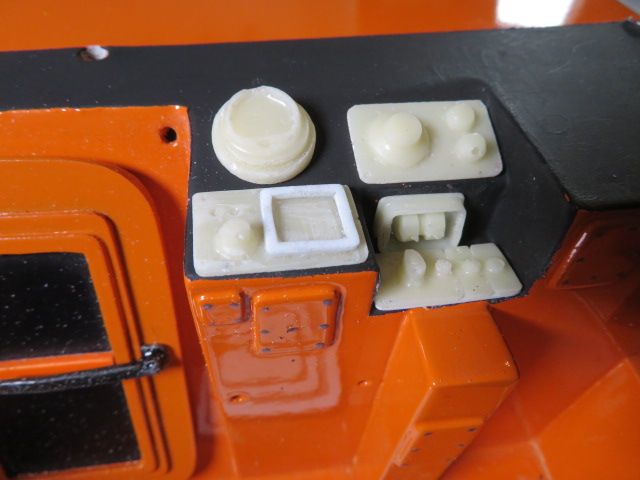

BROUGHT them in from the garage now to hasten the curing and setting time, and just maybe i'll get the second halves moulded tonight ready for casting some tomorrow…………dying to try out my new type of resin tomorrow morning.