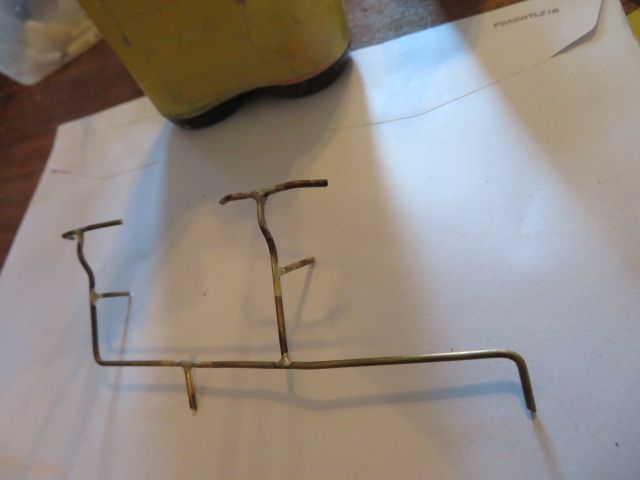

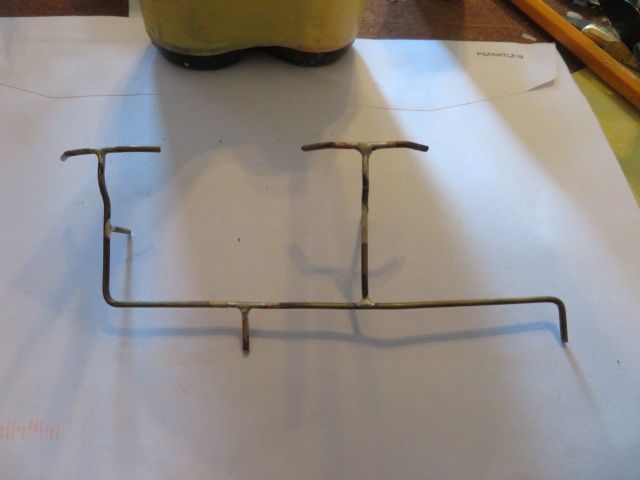

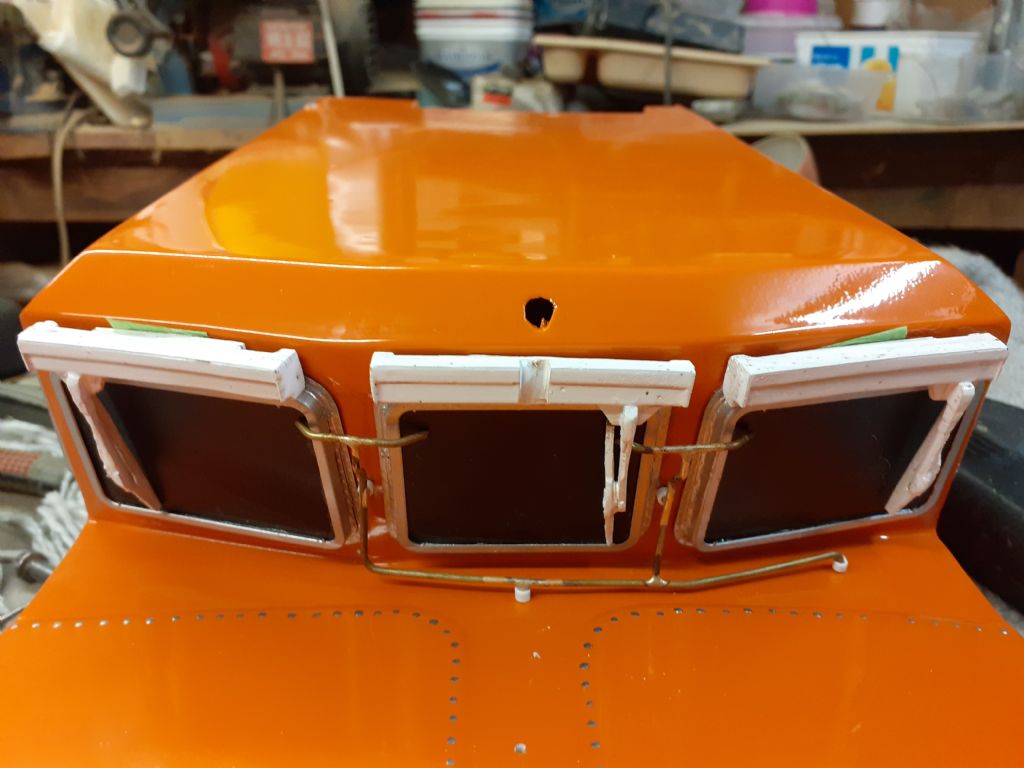

the third piece of fitting……..the Delta anchor and holding brackets.

TYNE class lifeboat progress goes awry!

although only a teeny weeny bit of the whole build of the lifeboat, but it has caused me to rethink and evaluate my modelling skills.

have you ever thought you would be saving time and using parts from another kit to substitute just plain common sense building.

its still sub zero outside with a bitter easterly wind straight from the Russian Steppes, and even the salt water model sailing lake at Fleetwood has frozen over, and my shed is as cold as a sharks heart, and so, now that the Atlantic is finished, and all parts for

Mick French's Mersey are all made and just waiting to be painted and fitted, i turned my attention to what more i could make in the warmth of my home.

one part was the structure for locating the Delta anchor on the starboard bow!……

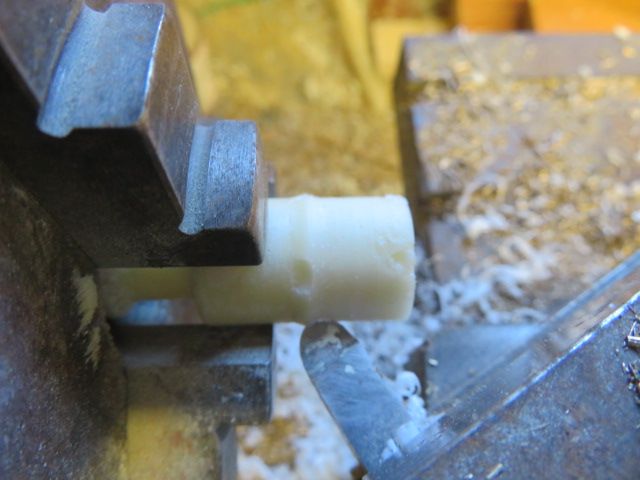

ahhh i thought, [well I didn't really think, just blundered on] and started using a bit of off cut moulding from the Atlantic kit, but one end needed cutting and refitting.

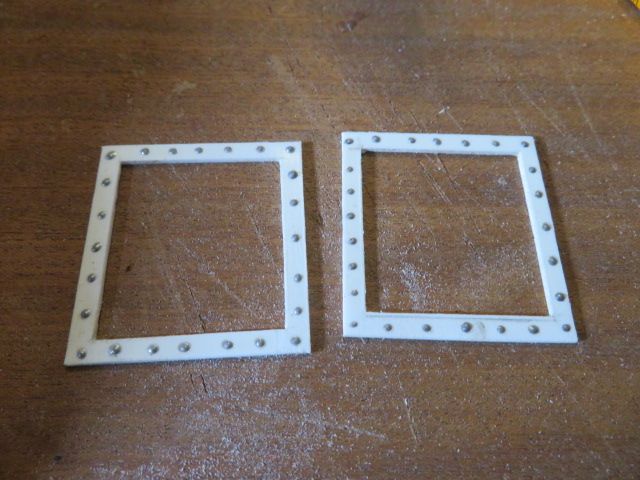

As i blundered on, i came to a stage where i actually began to think………this is so bloody awful and an absolute mess. And so i thought eventually………..why not just cut and make the item from plasticard,rather than a piece of rejected moulding, and total junk…..

And so i did………..and it took me less than half the time to make it than modify a bit of scrap crap!.sometimes……..saving time using something actually costs you much more time, and you get nowhere in the end.