I have to say, that for a "modern" fast afloat lifeboat I am and have really enjoyed building this Tyne, that I bought second hand from ebay.

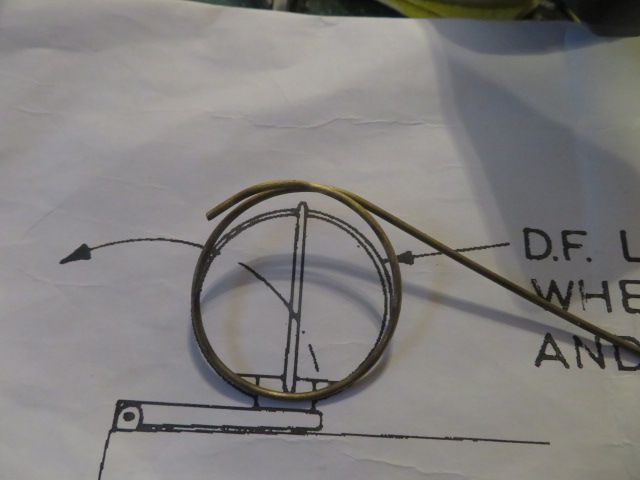

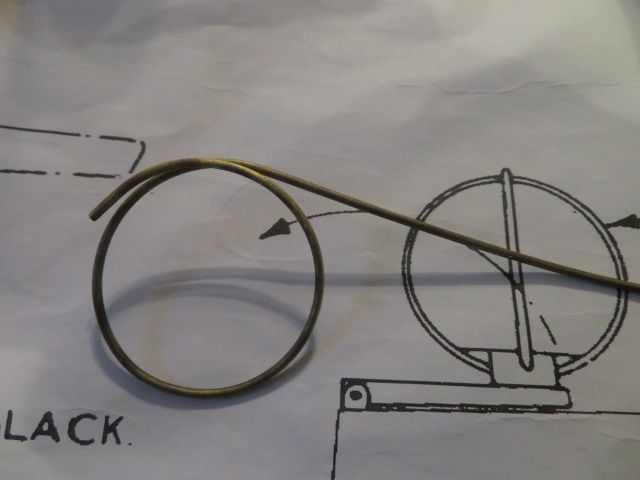

And although I paid a little over the odds because half of the fittings set didn't pertain to the Tyne, it has given me a great deal of pleasure building the scratch parts for the boat,

's Mersey, as I seem to be building a little of each boat at a time, and progress is slow on both boats.But TBH my workshop is so full of model boat parts and other crap, that I don't know where to turn with the two boats I am now building…….the Tyne andMick French

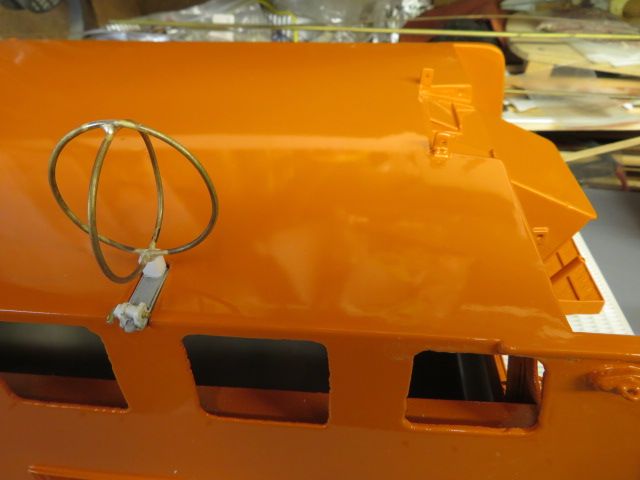

However adding the rack and air bags tonight has spurred me on!, and even though to is only a small part of the overall makeup of the boat, it has inspired me to make a decision.

However I have sold both of my old classic Watson lifeboats to an elderly gentleman with connections to Cromer in Norfolk where these two boats were based pre and post war and will be taking them to him whilst on business in January.

This will relieve some working space on the breakfast room table, and I am going to bring my Tyne in to place where my Shannon and motor sailor are now, once the Watsons are gone.

Thus giving space for working on the Mersey in my workshop, and getting that finished first, which will then come inside and sit where the Tyne is taking up temporary mooring rights.

I will also after Christmas begin to get rid of a lot of rubbish in the garage that is just hogging space.

Sorted!!! but in the meantime, I might just take all my tools back out in the garage, clean and tidy the house ready for the festive period and prepare for hopefully a new better year to come in 2021.

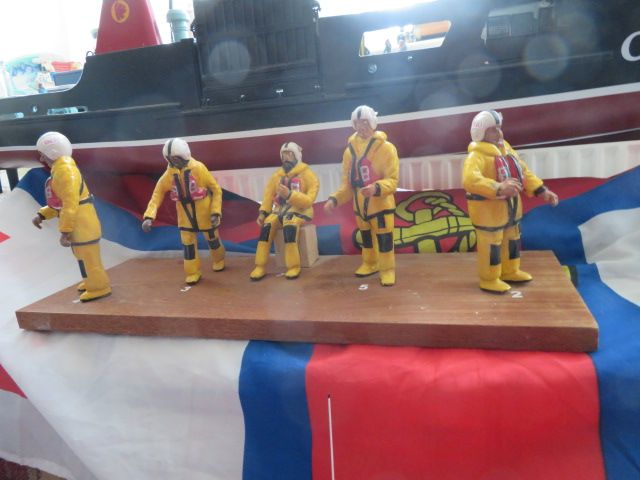

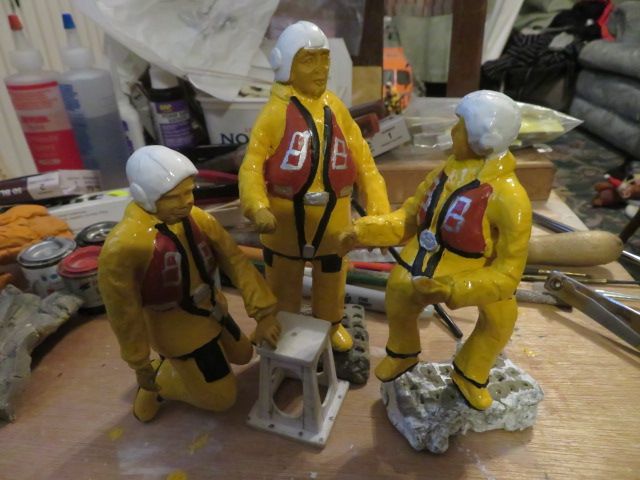

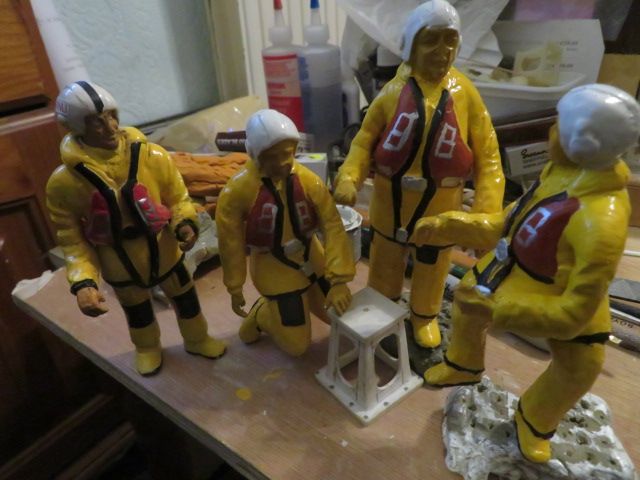

And so, this might be the last photos of my Tyne [and Mersey] until the new year.

Enjoy it as I do looking at it.

as Arnie said……….I'LL BE BACK!