Hi Bob,

a eureka moment again from me.

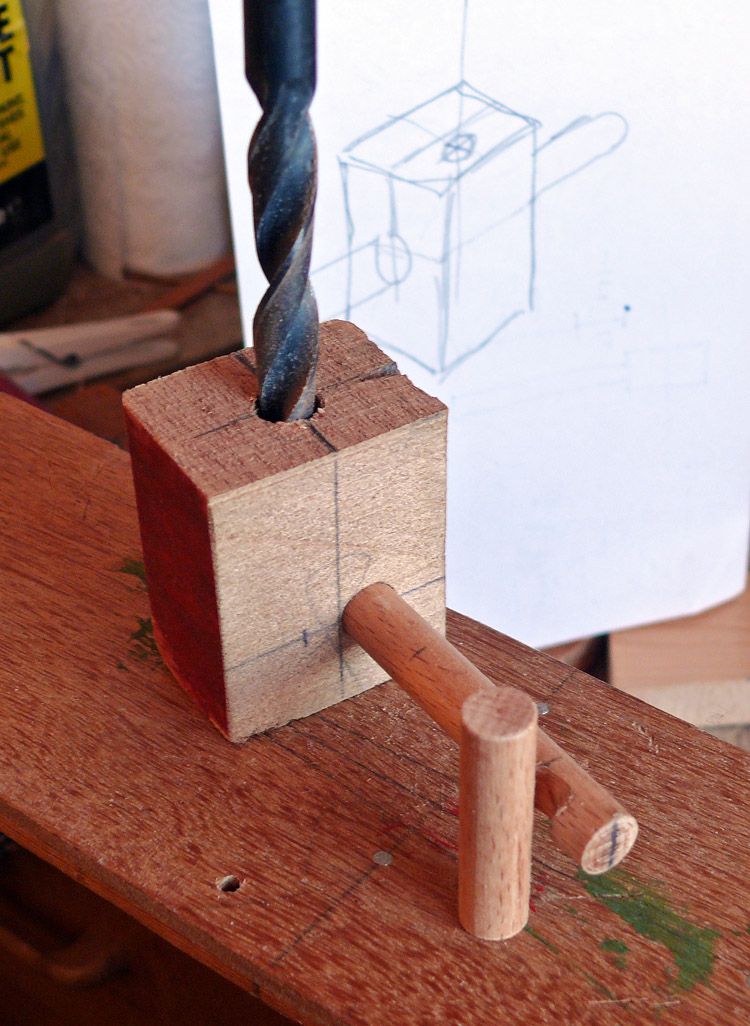

I like to work all materials to make model boats, mostly, and after my first visit to Dortmund got hooked on card modelling, that's paper card. Any way, there's a whole load of skills you can acquire when glueing up the cut out bits, to make things look a whole lot neater. The most useful is creating curvature to form a ships hull plates or sails, both requiring complex curves in three dimensions. I use wood dowelling of various diameters and a very soft rubber mat, about 25mm thick to roll the card on.

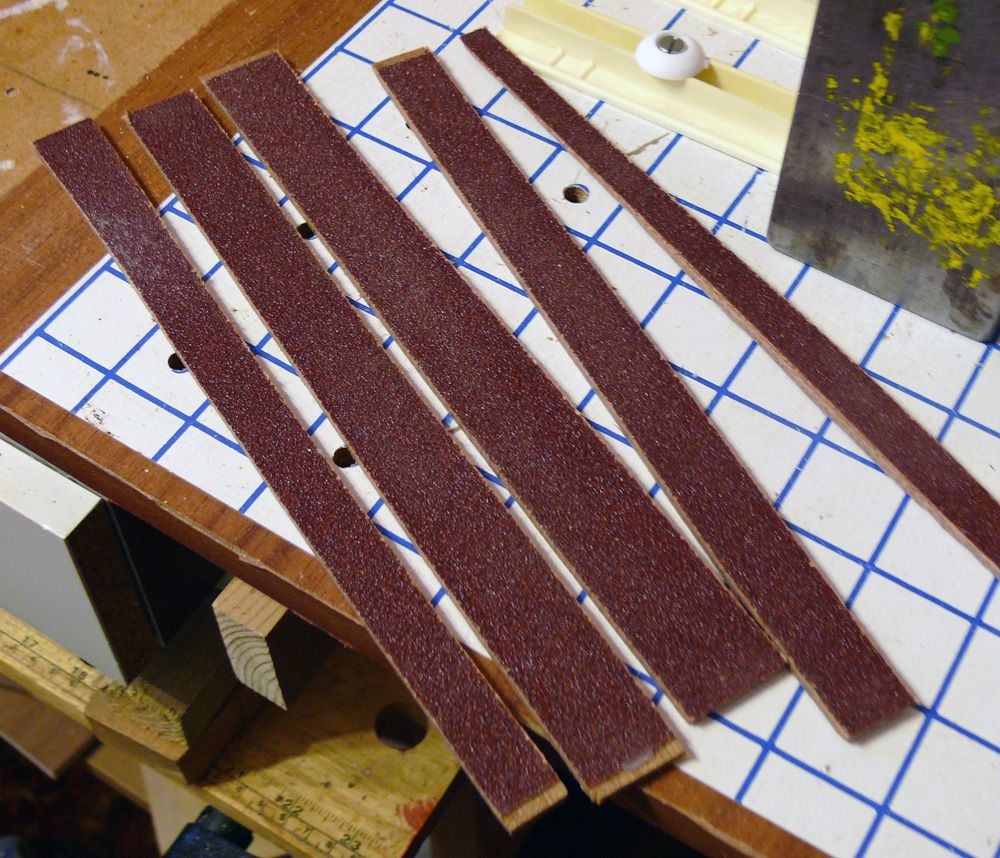

When making the navigation bouys I need to pre-curve the paper card so that when finished there was no strain at the glue join and the shape was natural. I applied the dowell tecnique to plasticard and it works, though it takes longer and more effort, but the plastic behaves just as the paper and rolls up into the required rounded shapes perfectly.

These cut outs are flat, but when rolled on the mat under dowel, they take on their designed shape.

Once shaped the glueing is simple and under very little or no strain.

Now others might have known this plastic shaping trick, I did for paper, but it was quite an eye opener for it to work so well on plastic. I've even had success on wood and thin ply (birch 0.4 to abot 0.8mm).

Kimosubby