Epoxy sheet is quite expensive here and not always available. I have the raw materials so making the keel box sides was very easy.

I have various random weights of woven and non-woven glass. I have no ide what the weights are so they are selected on the basis of the lightest material that I think will do the job. This saves on resin too as there is less to wet out. The sides of the keel box are birch ply as supposed to Liteply and so most of the required strength is in the wood and the epoxy provides the wear surface and the water resistance.

A piece of ply was cut sufficiently large to do the two sides with a bit of a margin and the epoxy and fabric laid up on the wood trying to get the amount of epoxy uniform over the entire surface.

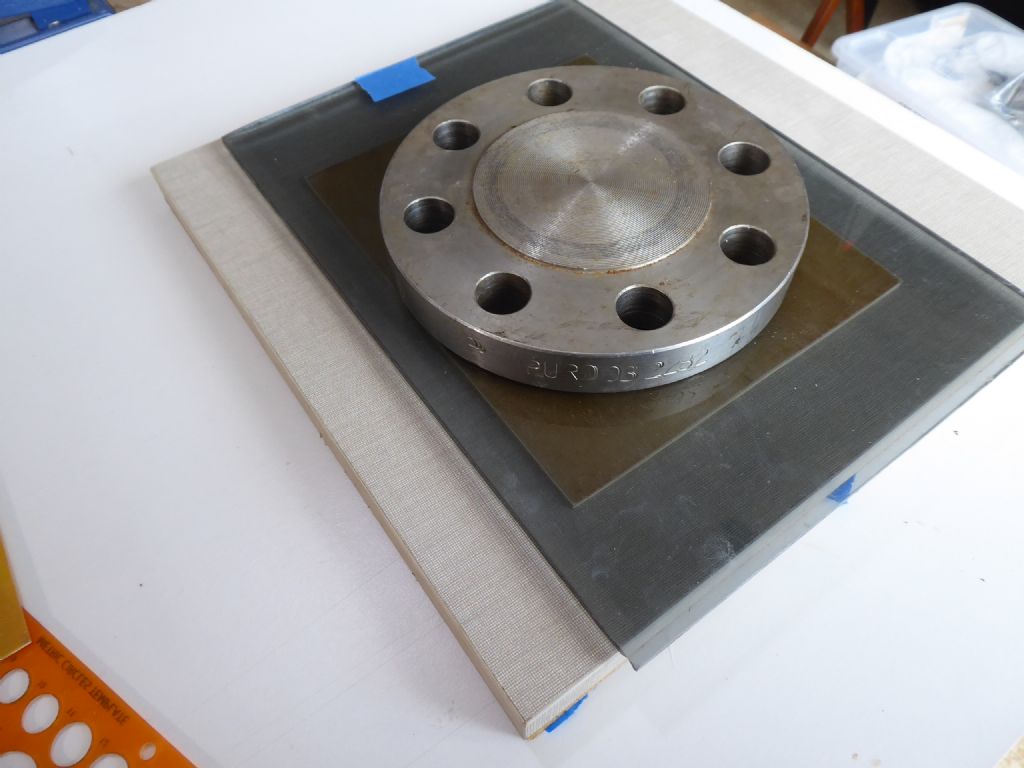

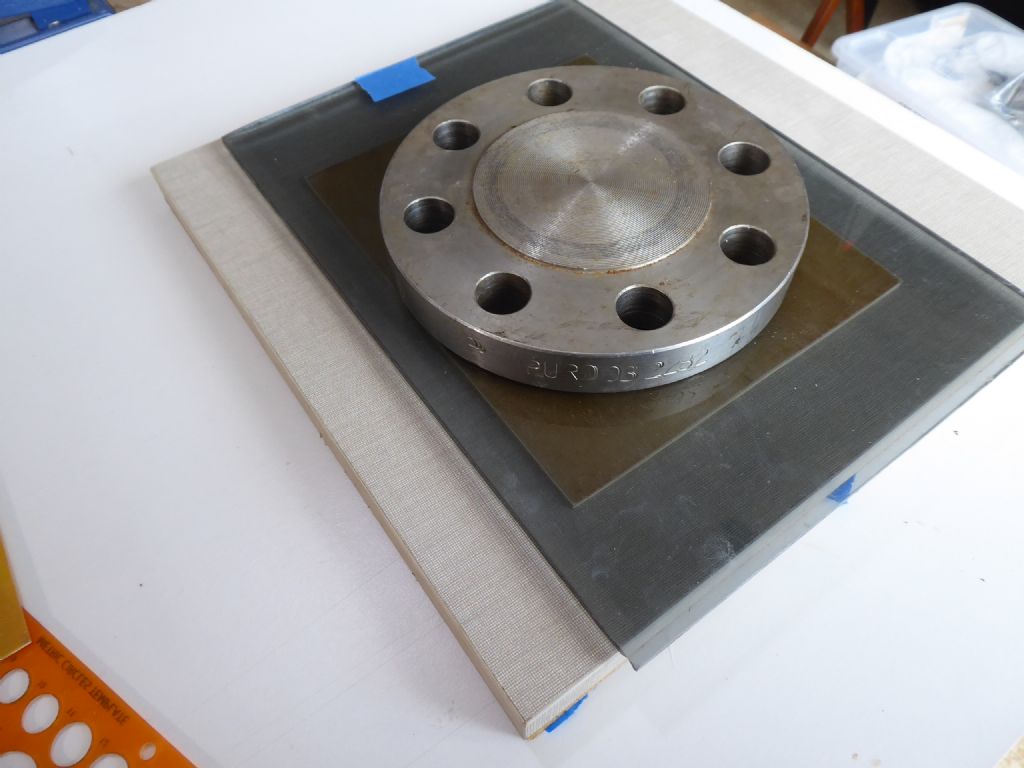

The lay-up was then covered with a piece of waxed glass and then weighted down.

Actually I used all the weights I could find to squash the glass onto the epoxy. The full weight was left on for about an hour to let any excess epoxy flow out of the edges and when the epoxy was just starting to gel, the weights were removed and the work put out in the sun.

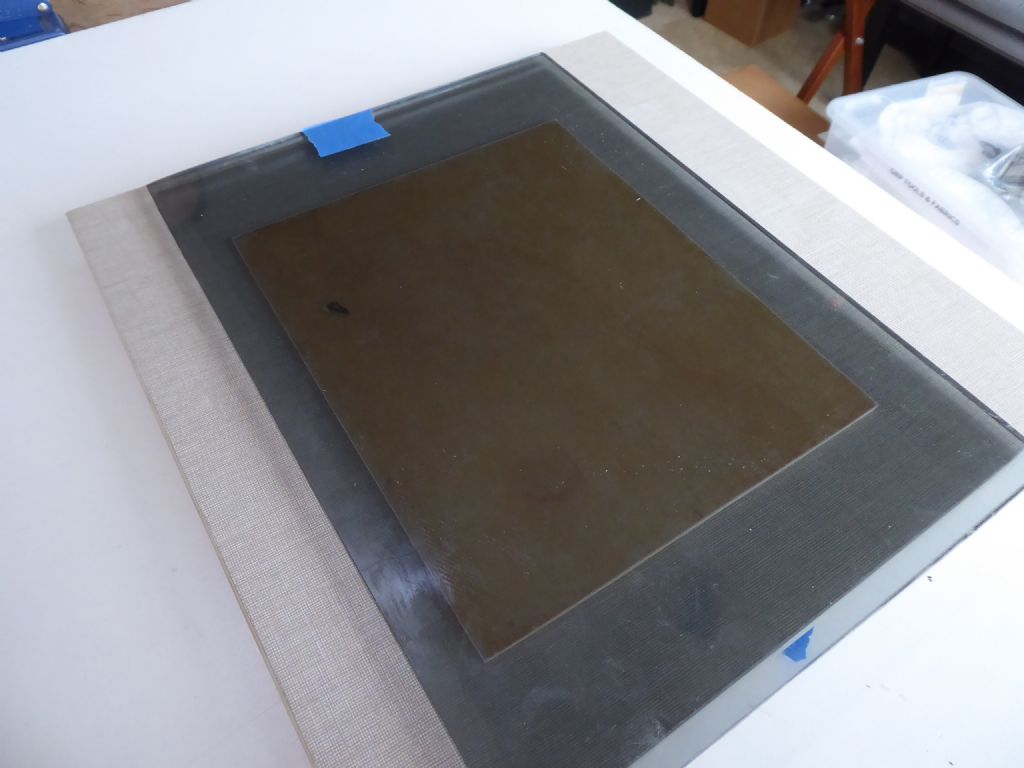

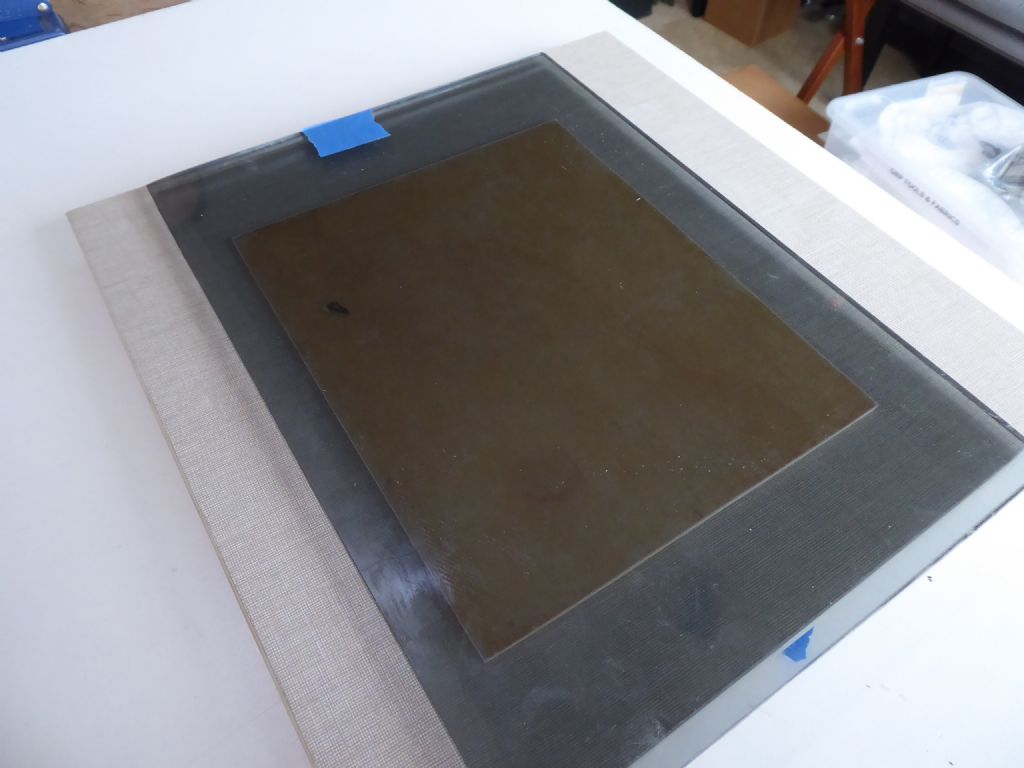

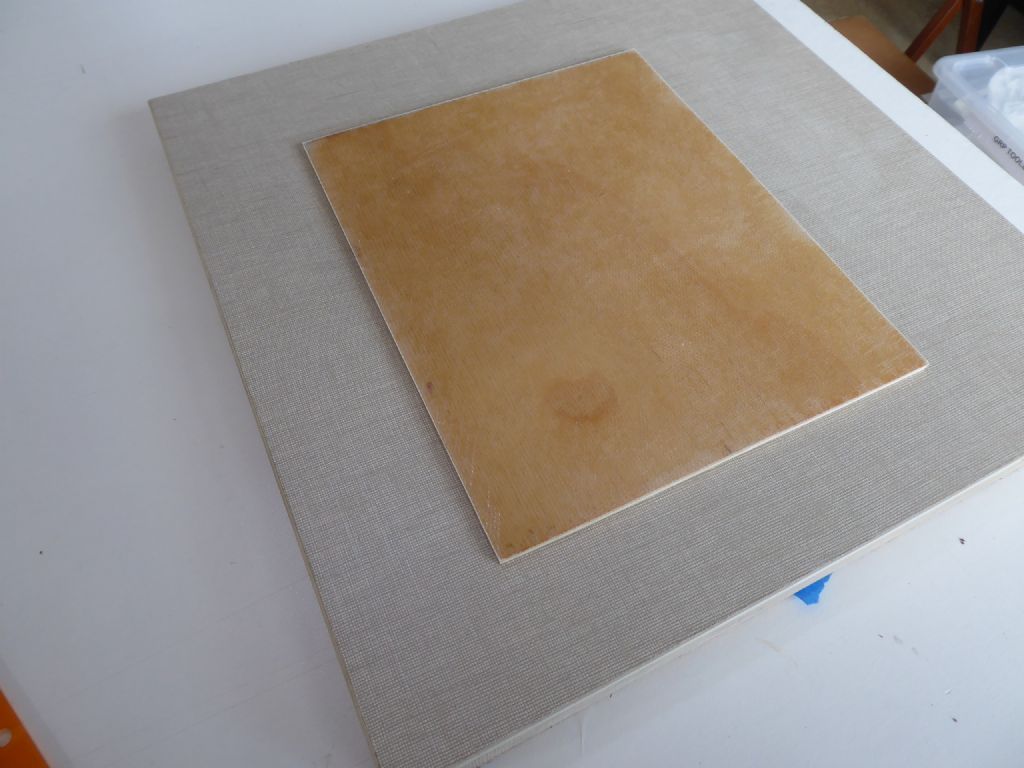

Looking like this. The smoked glass absorbs the heat very nicely and I got an excellent cure in about 1 1/2 hours reaching a temperature of about 65 degrees (ie too hot to touch)

The work was then brought inside to slowly come back to room temperature before releasing it. This is important to maintain complete flatness through the temperature change. I sincerely hope it will never get as hot as 65 degrees again!

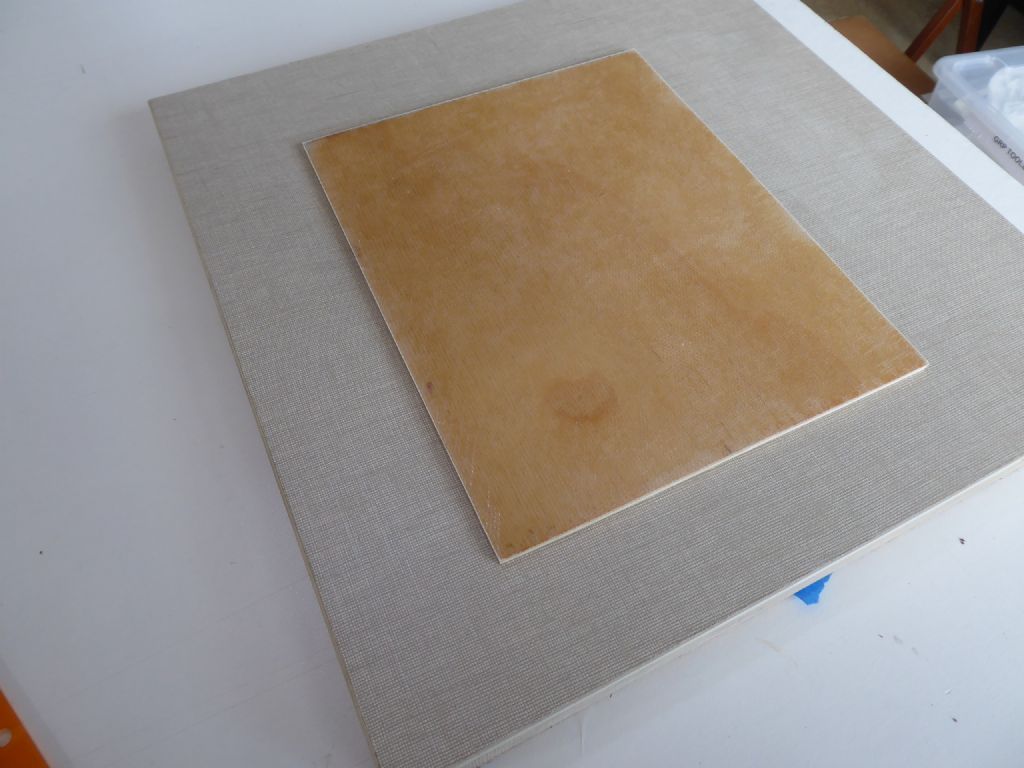

Here is the finished sheet and the epoxy is rock hard.

It was not quite as good as the bought-in stuff as the weave did not completely fill. It was however fully wetted out so it will perform fine. It would be nice to have vacuum bagging equipment (one day) and then the weave would have filled 100%. It would have been a lot more weights to match atmospheric pressure.

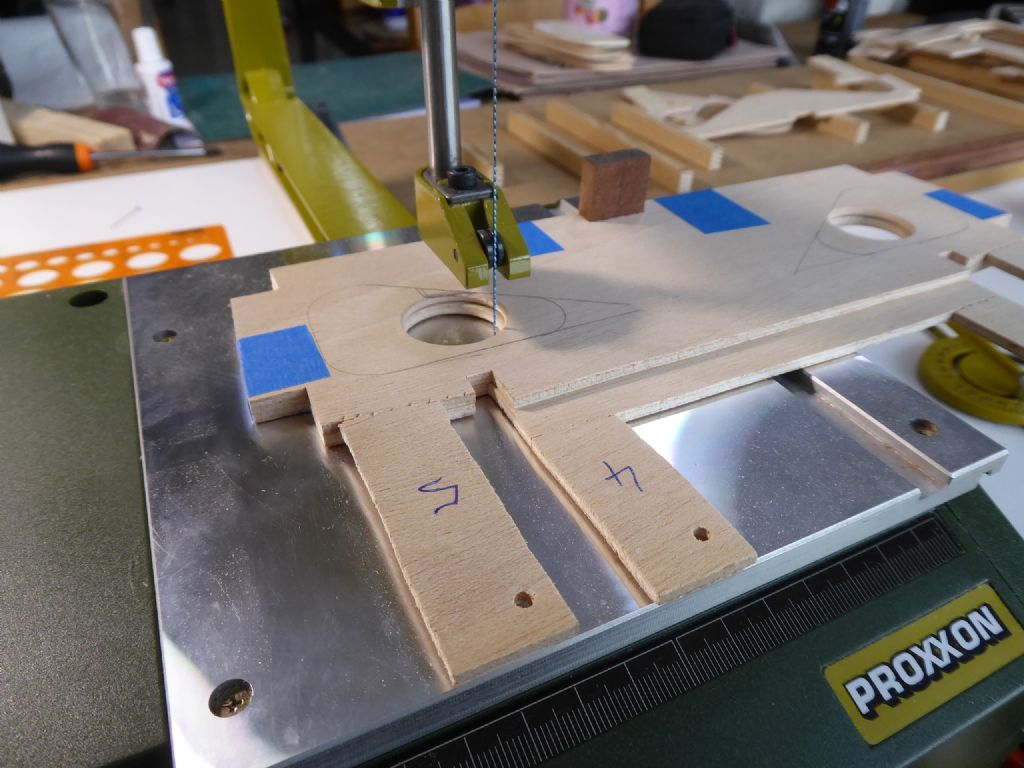

The epoxy faced ply is now ready for cutting out the two side.

Tim R

Richard Simpson.

Richard Simpson.