The new lead bulb is turning out to be a lot of fun.

The original would not come off the Tufnol fin and got mangled in the attempt. It was also a homemade section probably influenced somewhere along the line by Vic Smeed's book "Boat Modelling". By modern standards it is very dumpy and extensive tank testing for RC racing yachts shows that long slim bulbs have lower drag. They can be so thin that they become fragile so a compromise is reached on the diameter to length ratio and usually they are reinforced with a rod. As is happens, ultra slim keels are not as efficient at full size and there is a very definite optimum beyond which increasing the length does nothing and causes unwanted side effects.

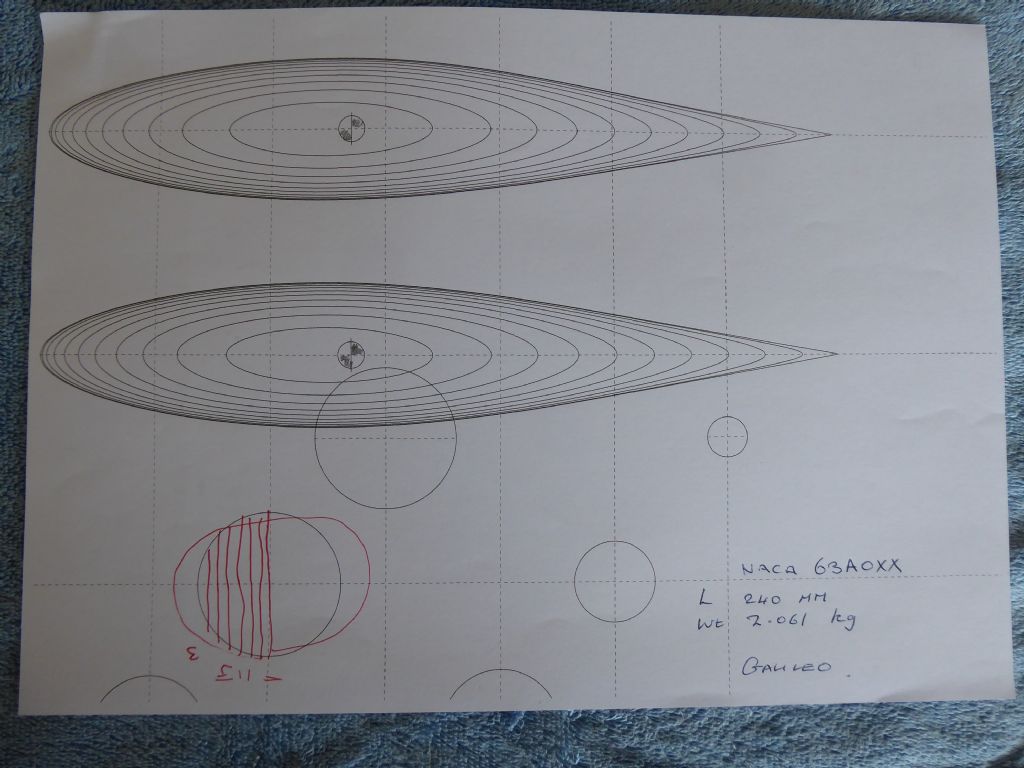

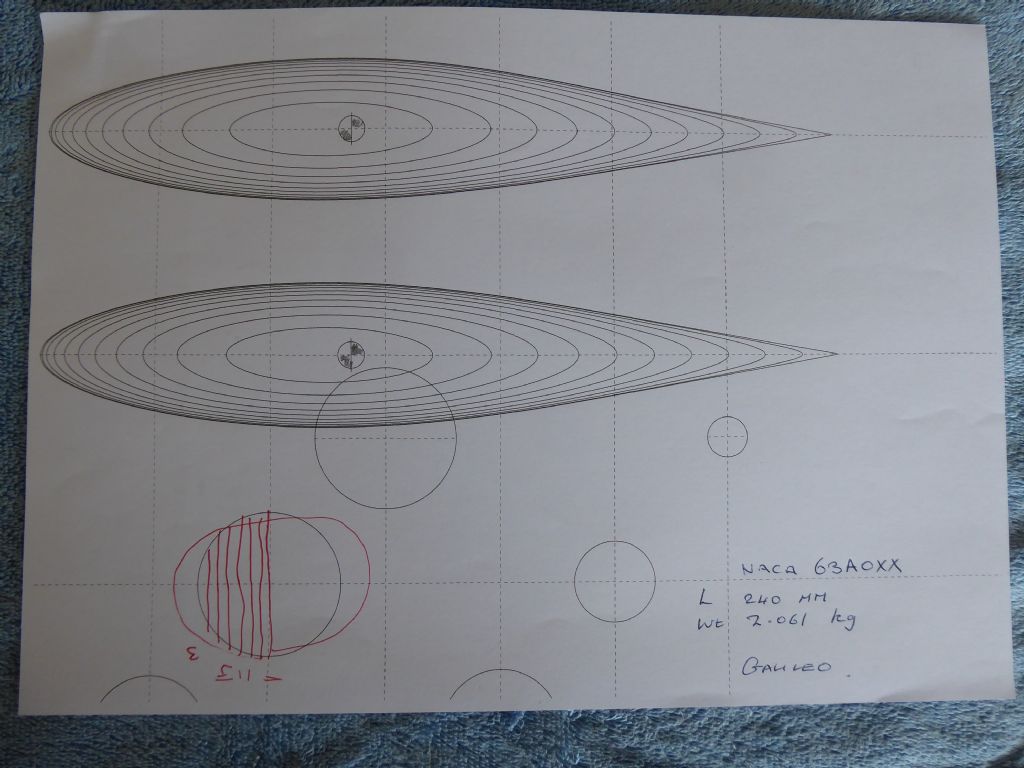

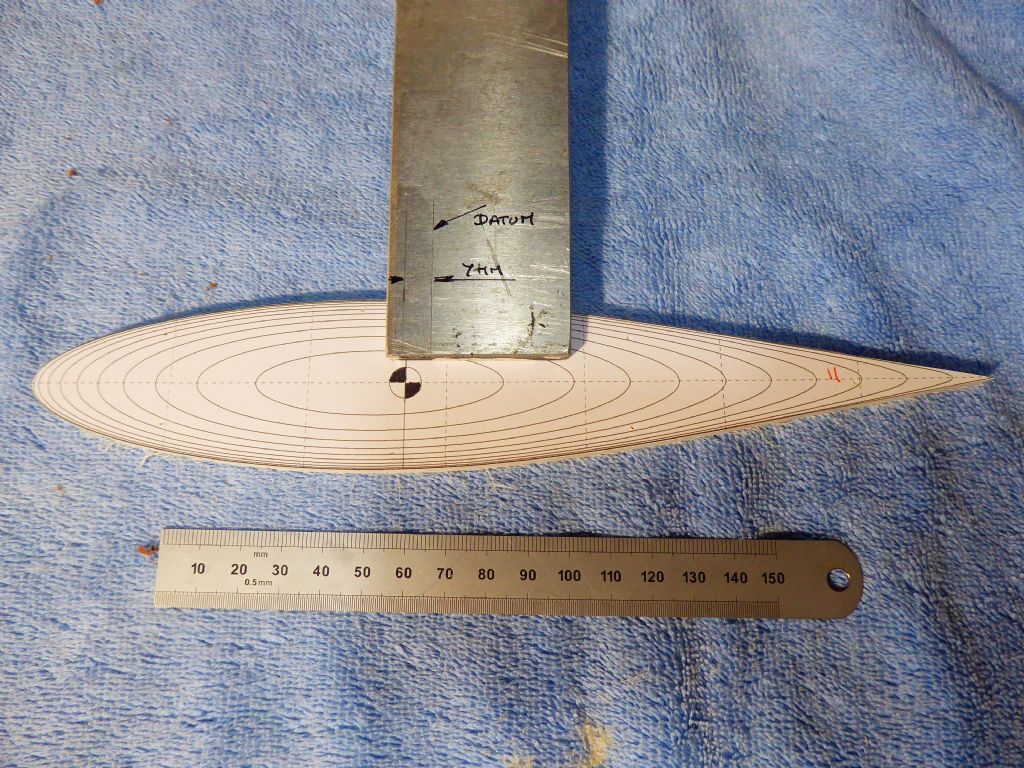

This is the design for my keel and before I go any further I should acknowledge the use of Marko's Bulb Calculator that you will find if you click the title. Thank you Marko!

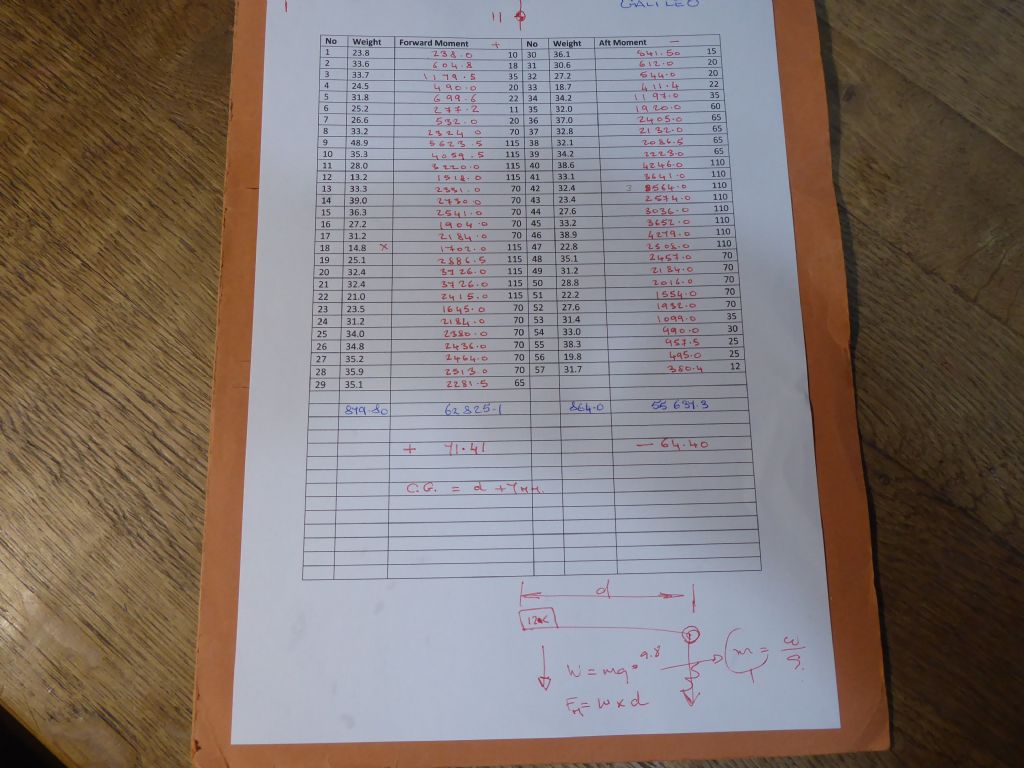

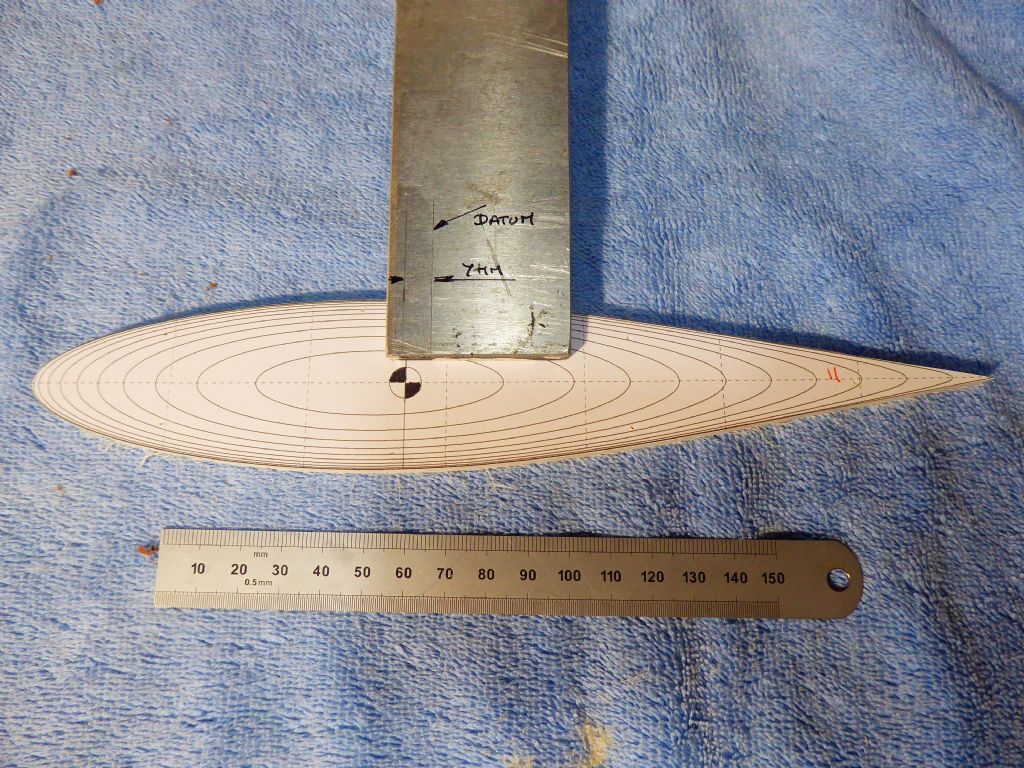

It has a selection of aerofoil sections where you can decide the ratios and proportions. You can invent your own if you like. I decided that I wanted the bulb to be no longer than 240mm and that it should weight a fraction over my target weight of 1.49 kg. The reason for going slightly overweight was to have a shrinkage allowance (roughly 1.5%) and to give me something to dress smooth if the casting comes out a bit lumpy. I chose the option that gave me 2.06 kg and chose to divide it into 2mm slices as that will be the thickness of the balsa sheets I will be using to make it.

Conveniently the cg is marked on the drawing so there is all the information you need.

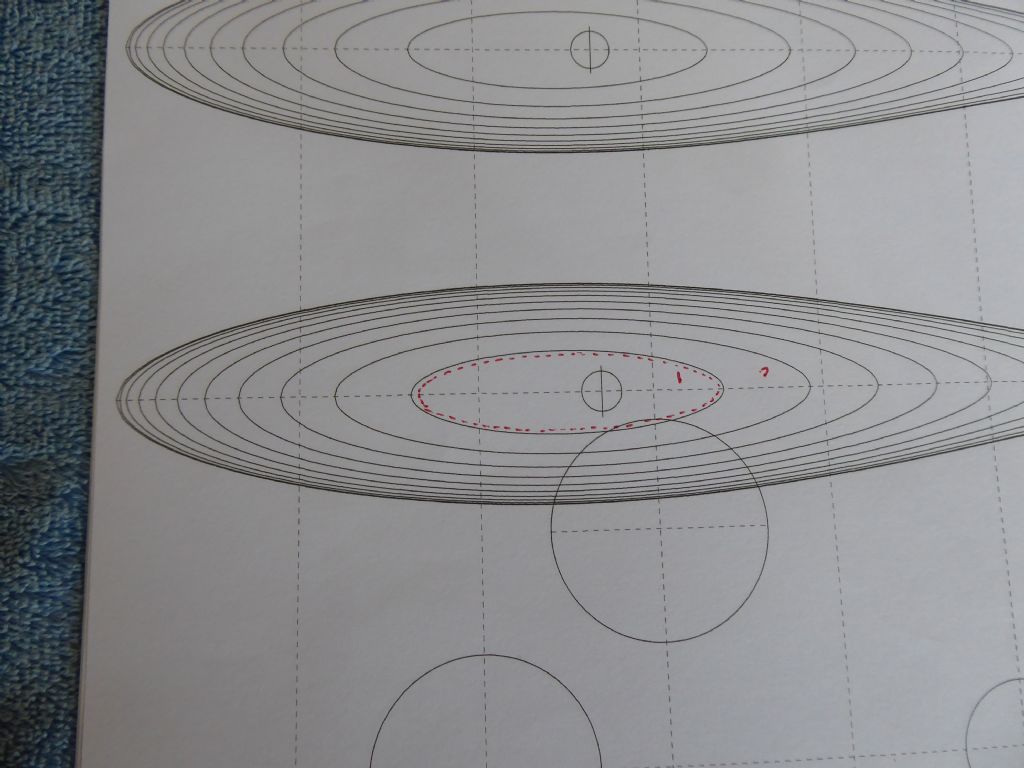

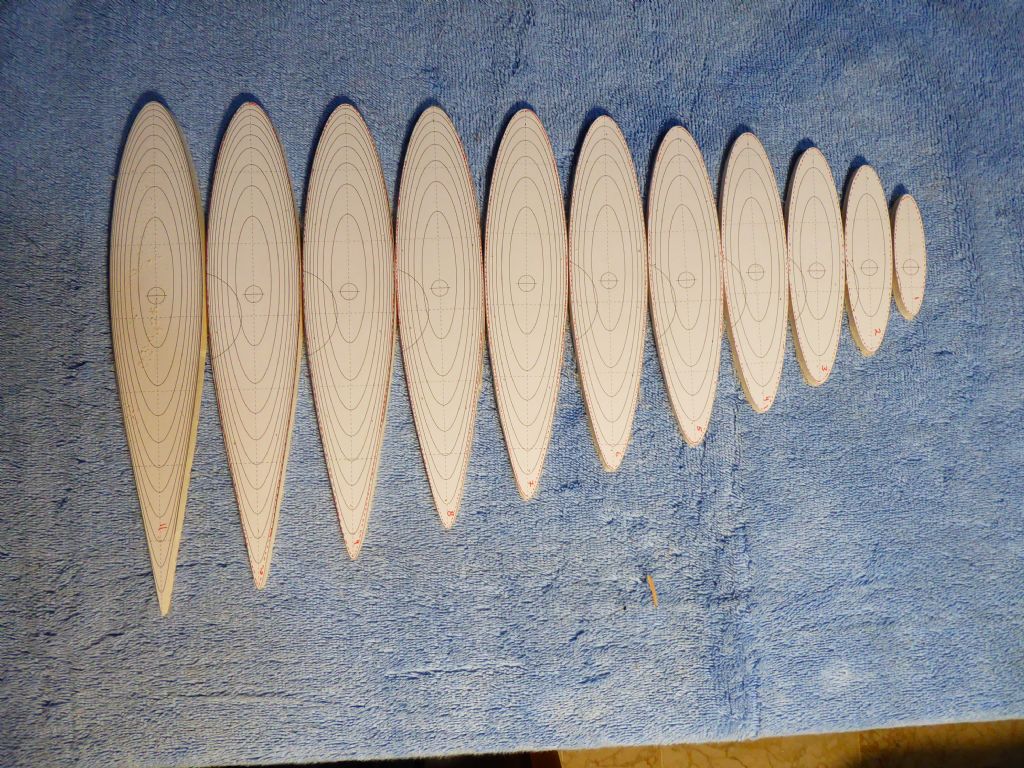

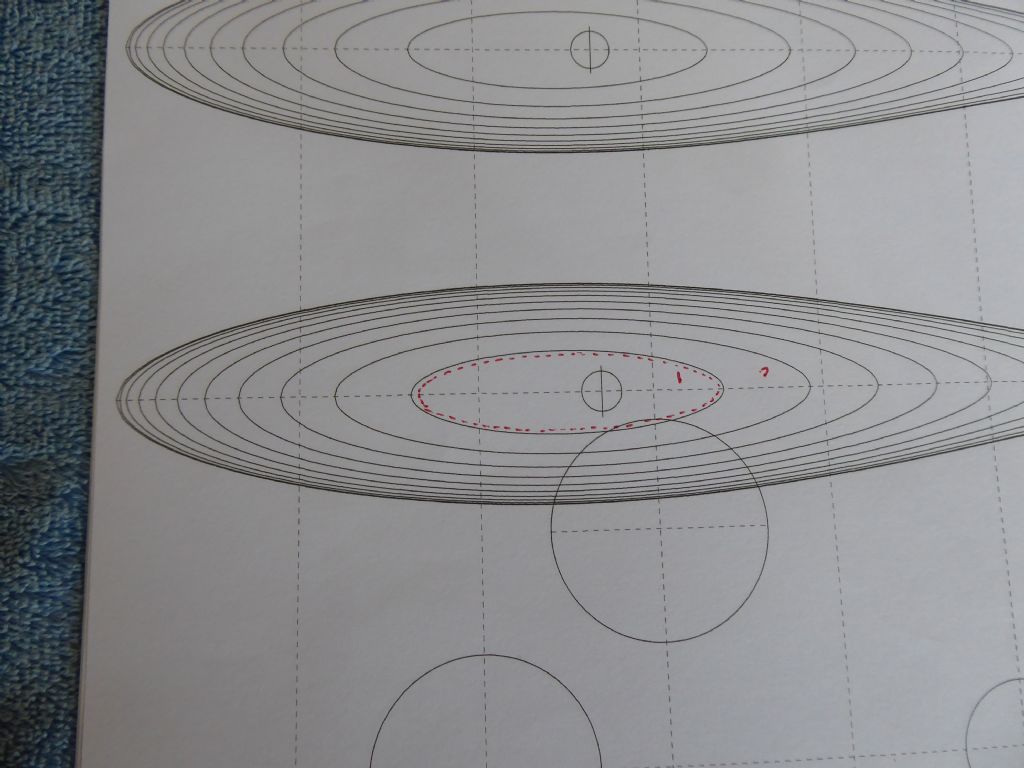

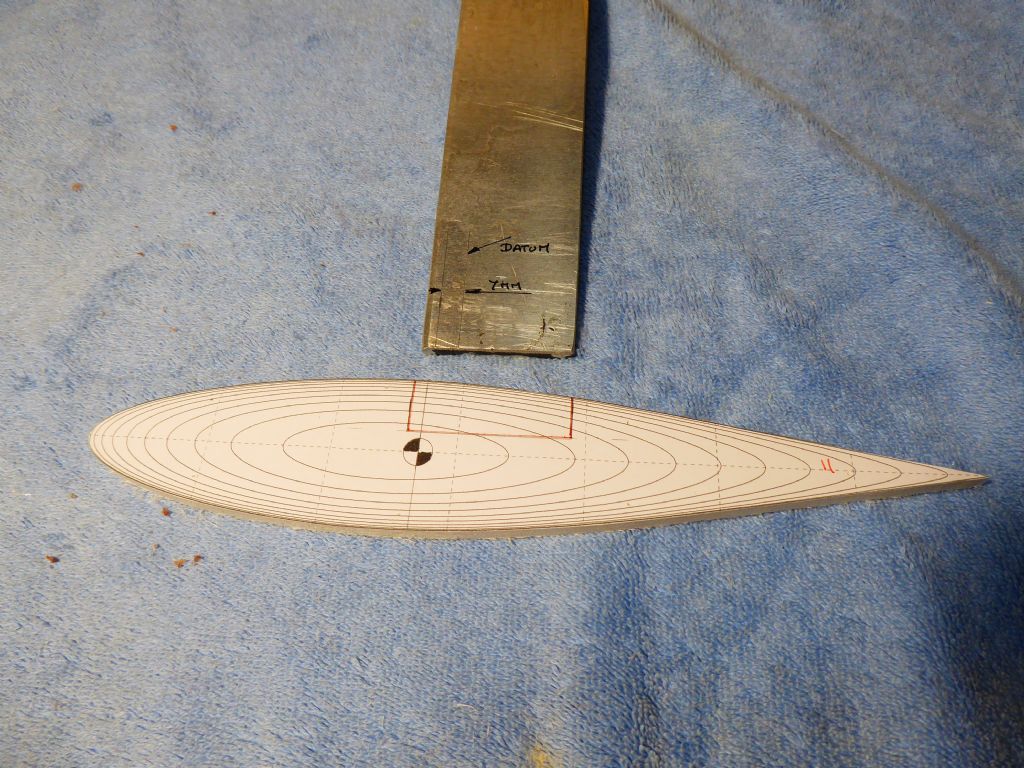

I printed off a number of sheets and outlined each laminate in red and numbered them 1 – 11. They are then cut out roughly and then stuck to the balsa sheet with Pritt Stick (easy to remove the paper later) The laminates are done in pairs and sanded to the outline using my Proxxon disc sander which is the most efficient dust maker I have ever known.

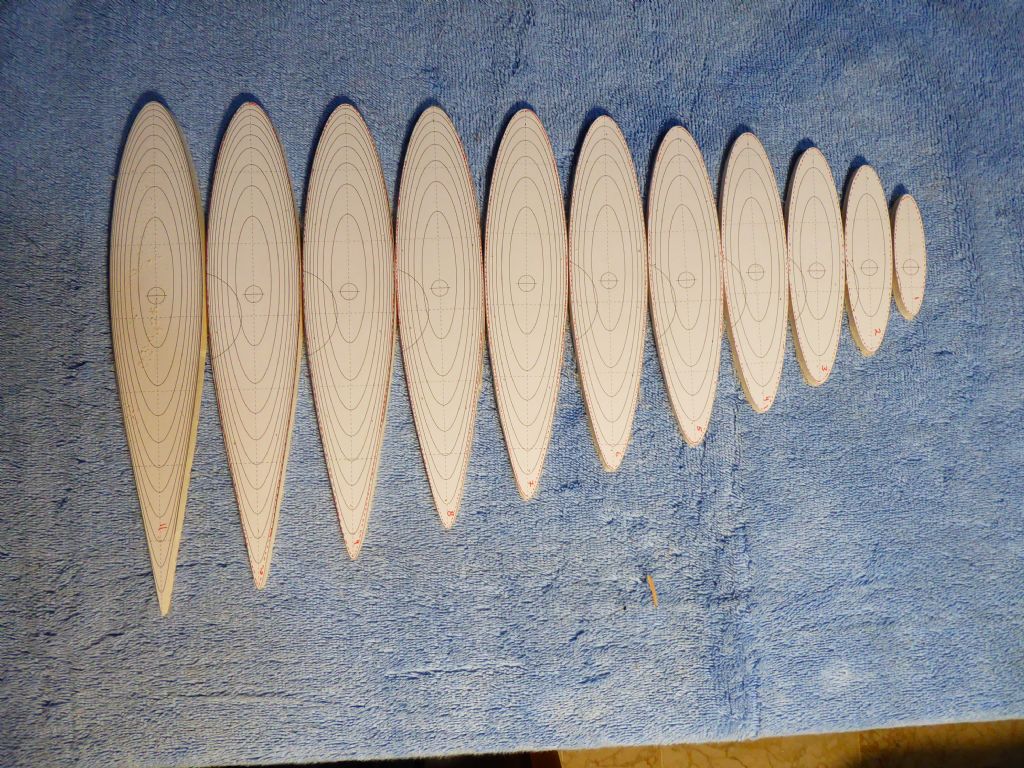

Here are the 11 pairs of laminates ready to be stuck together like building a "bread and butter" hull. The printed reference lines makes it easy to line them up for gluing.

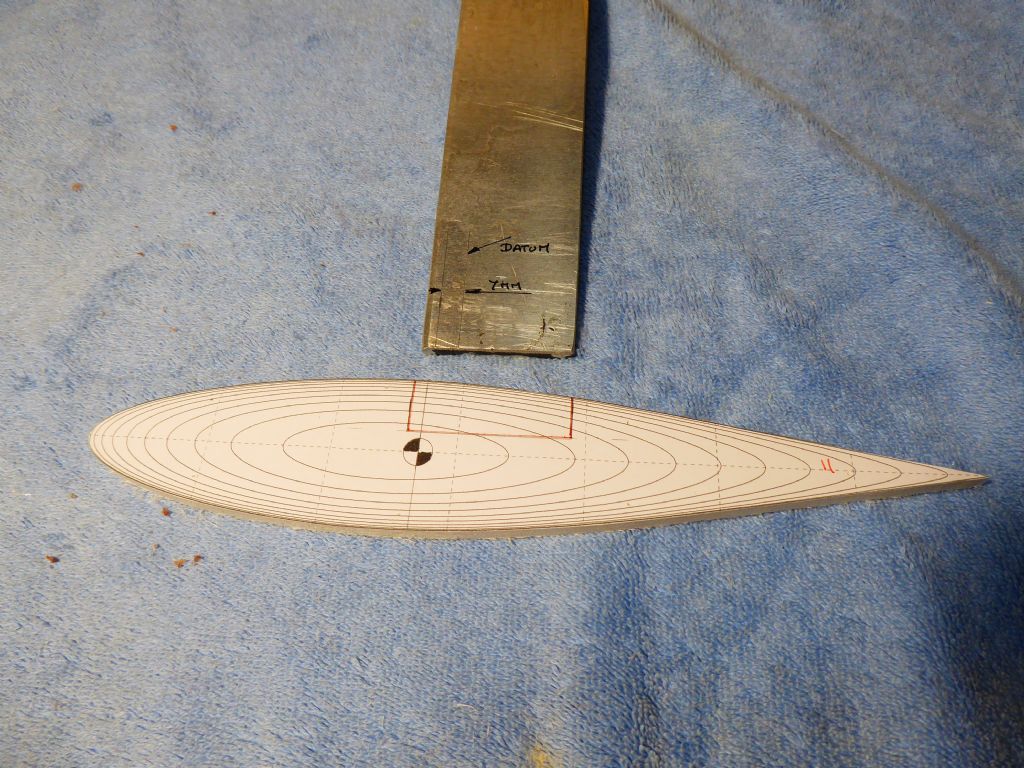

The two centre laminates were made from 3mm balsa to give me the 6mm slot for the alloy fin. This makes the bulb slightly oval in cross section and will increase the weight very slightly to my advantage. The slight ovality actually looks very nice. Here the cg is lined up with the 7mm offset that I previously calculated from the loose weights.

The 3mm pieces were marked with the slot and cut out.

To allow the fin and bulb to fit like this.

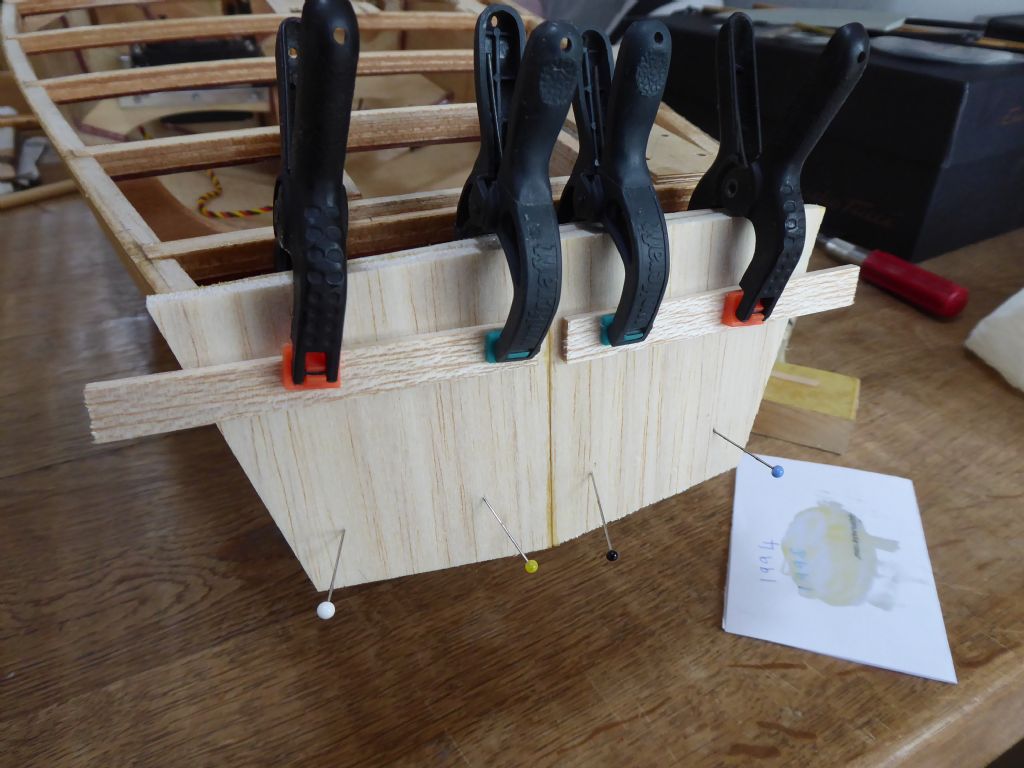

Sticking the laminates together in pairs initially for easy clamping.

And gradually building them up

To finally build up the basic shape of the pattern. Here I am using elastic to hold everything tightly together while the aliphatic glue dries.

The reference lines can be seen that makes sure each section is in the correct place.

First work done with the Davids plane taking the plank fairly close to the joints

Sanded smooth with 240 grit and 320. As soon as the lines between each piece are sanded out you have reached the correct size and shape. Really quick in balsa with about 15 minute using the plane and about 1/2 sanding.

Then a coat of sanding sealer to harden it up a bit and fill the grain before final painting.

Tim R

Tim Rowe

@timrowe83142

Hi Ray

Hasn't Leeds castle got a moat for goodness sake

Nice place but a long way from Leeds.

Regards

Tim R

Ray Wood 3

@raywood3

Hi Tim,

Yes some brilliant water around the Castle, thought I was buying a time share there, £29 each admission, but the tickets last us a year, there is also a maze which I would still be in it if our grandchildren hadn't rescued me 😀

Regards Ray

Tim Rowe

@timrowe83142

Hi Ray

I know the maze having been there myself. They give you a year on the ticket just in case you don't make it out! You were lucky, a very narrow escape. I found it quite scary.

Never did find out why it is called Leeds castle in the middle of the garden of England.

Days starting to get warmer so the beginnings of the sea breezes. That means safer sailing off a lee shore in the harbour. If anything goes wrong at least the boat will drift in.

In the summer you could sail all around Mallorca on a reach. A great column of hot air rises out of the centre of the island sucking air in from all around. Mind you, you would need quite a fast yacht as it is a long way. I think it has been done by a big cat.

Tim R

Ray Wood 3

@raywood3

Hi Tim,

Many a finger tip at risk with a David plane, essential tool 😀 one more bulb pattern and you'd have a pair of tip tanks for a Jet Provost 😁 Oops

Regards Ray

Tim Rowe

@timrowe83142

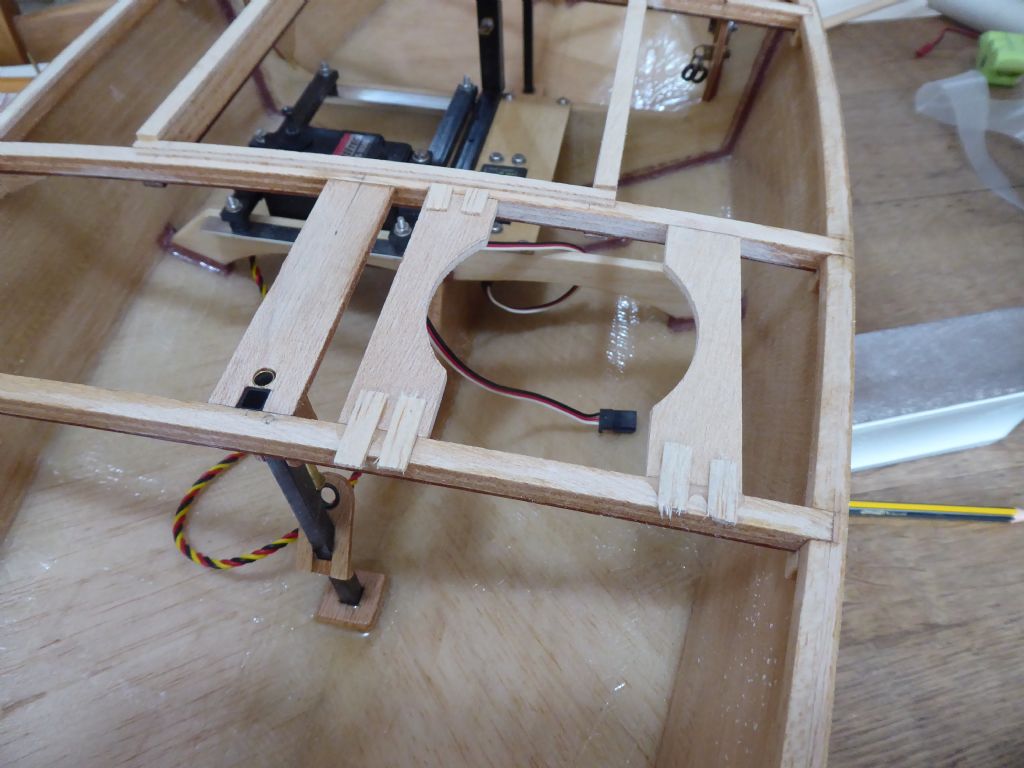

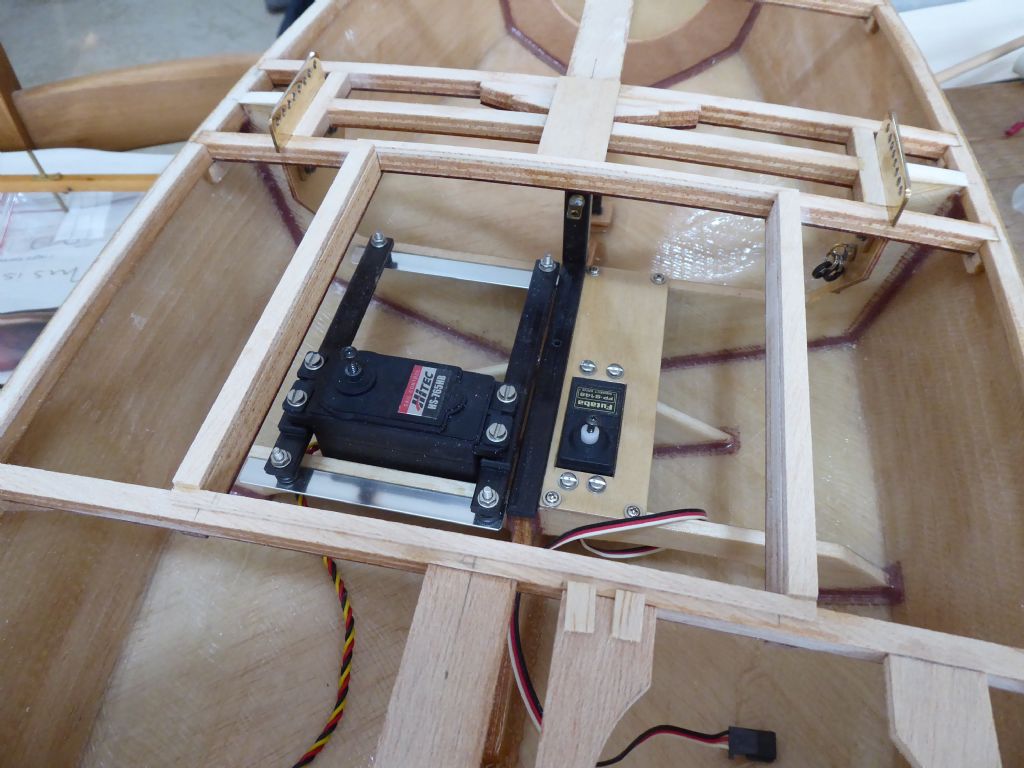

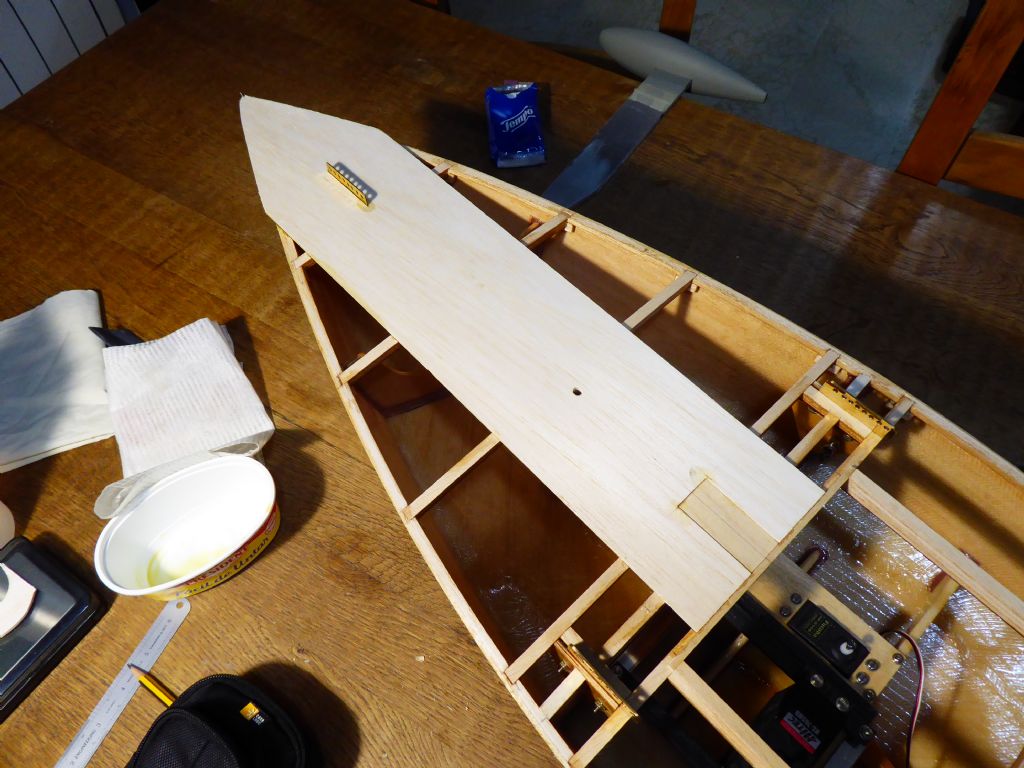

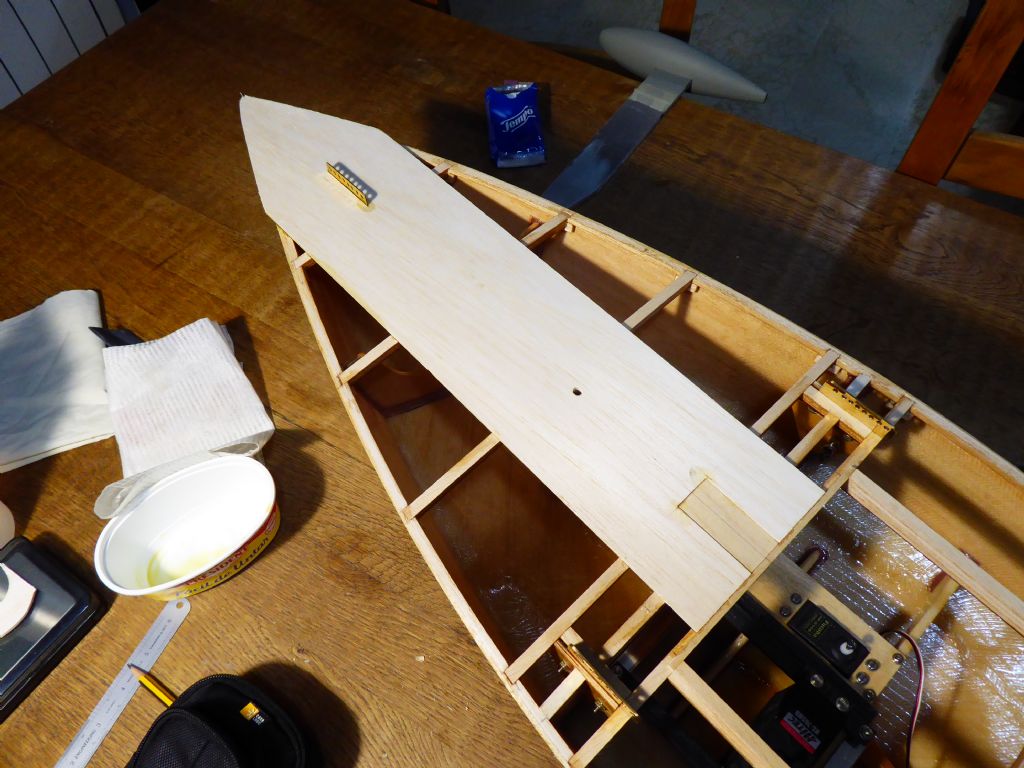

No more excuses. The deck has to go on sometime so a final check that everything is sealed, no sharp glass fibre strands and all the dust is vacuumed out. Of course one the deck is on it will not be possible to seal the underside so this has to be done beforehand.

Here are the sub-deck panels with the slots for the forestay and shroud fittings, the slot for the hard point mast step, the slot for the Go-Pro mount, the rough hole for the pot and the cut-outs for the hatches. Using the same method for the initial sealing of the hull, the underside of the deck is covered with a layer of heavyweight tissue fixed with epoxy. Only a few grams of material added keeping the epoxy to the bare minimum to just fill the tissue.

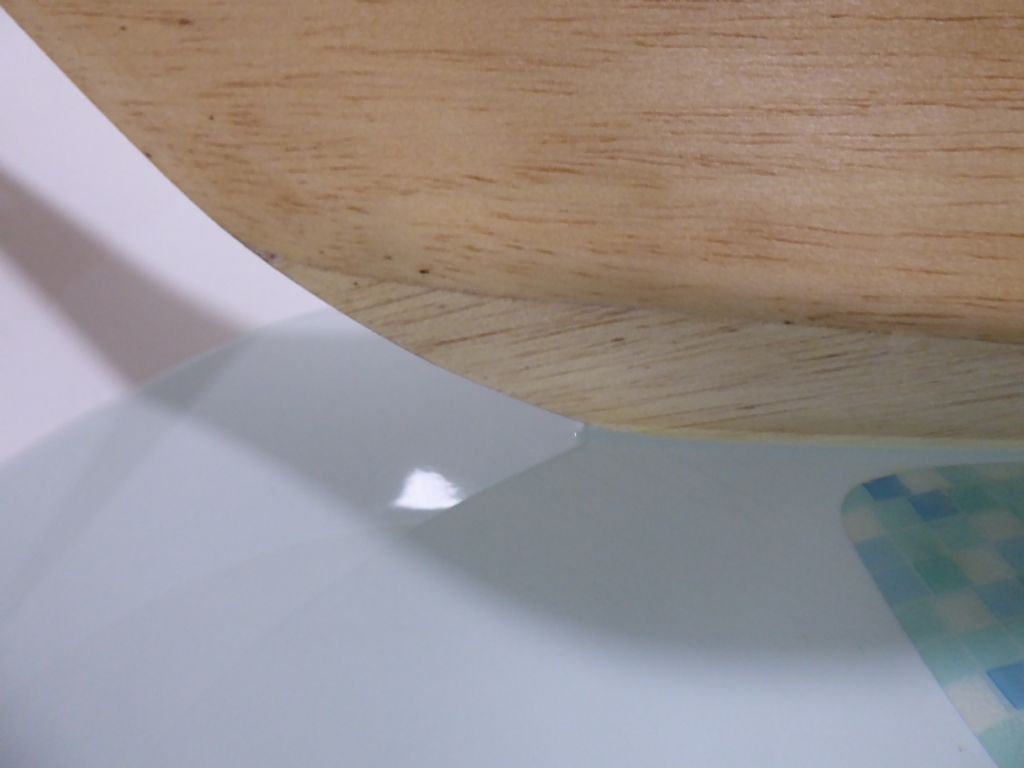

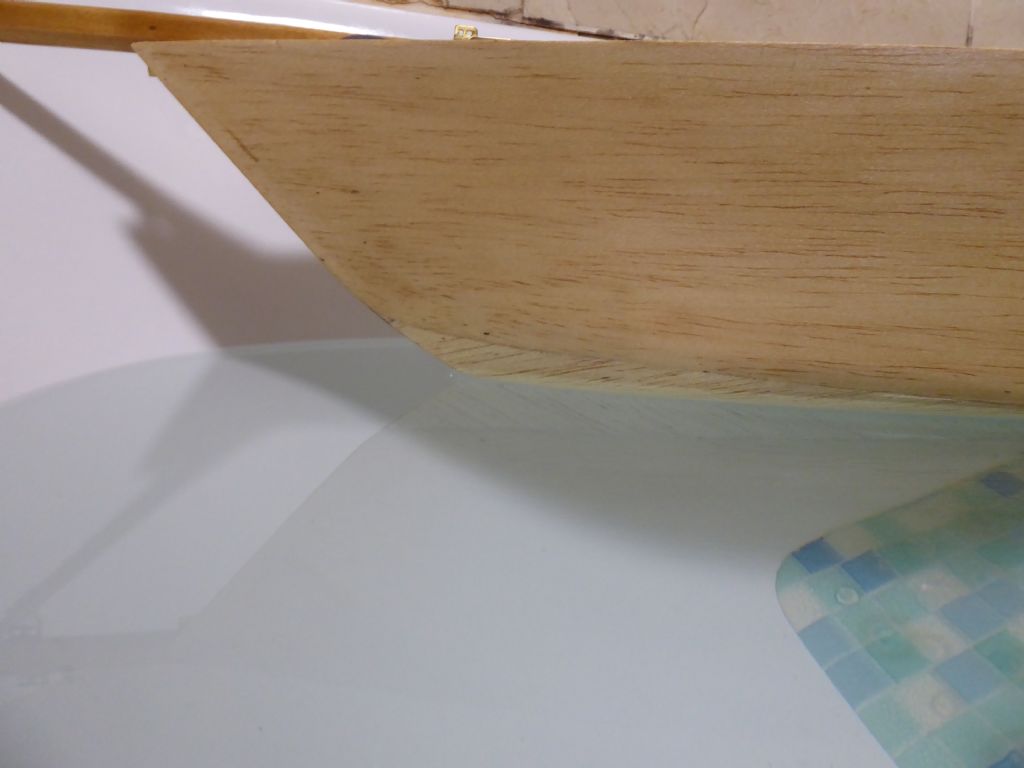

The tissue give the balsa incredible toughness. These two photos show a piece of off-cut from the pot bent over at 90 degrees. No cracks in either the balsa or the tissue.

Here the front centre section of deck is in place

And here the aft sections.

Tim R

Tim Rowe

@timrowe83142

Finishing touches to the subdeck

I am using epoxy to join the deck panels and fix to the hull. The centre section is masked meaning that I can apply the glue quickly to the edge without getting it all over the surface. Keeping the glue off the surface means that I will only have to sand a very fine glue line rather than hard lumps. Likewise, the edge of the section to be fitted was masked.

The underside of the sub deck was previously sealed with tissue and epoxy so it was only needed to "paint" the glue onto the deck beams and deck edge. By making sure everything is coated it does not matter too much if there is a slightly open joint somewhere. I won't be able to see inside if all the joints are perfectly tight but the wood will at least be sealed. With everything effectively capsulated there should be virtually no expansion or contraction of the wood due to moisture changes and I am hoping to avoid any later cracks in the finishes.

Tim R

Tim Rowe

@timrowe83142

Sundeck now complete.

A truly authentic new build as the bilges are full of dust and debris just like the real deal.

The stand is one of the first things I made when I came back to modelling. For a number of reasons working at low level does not suit me so I made this folding universal stand from stock aluminium extrusions from the local bricolage (sort of one step up from a hardware store in Spain) I will come back to the stand in another thread as it is immensely useful.

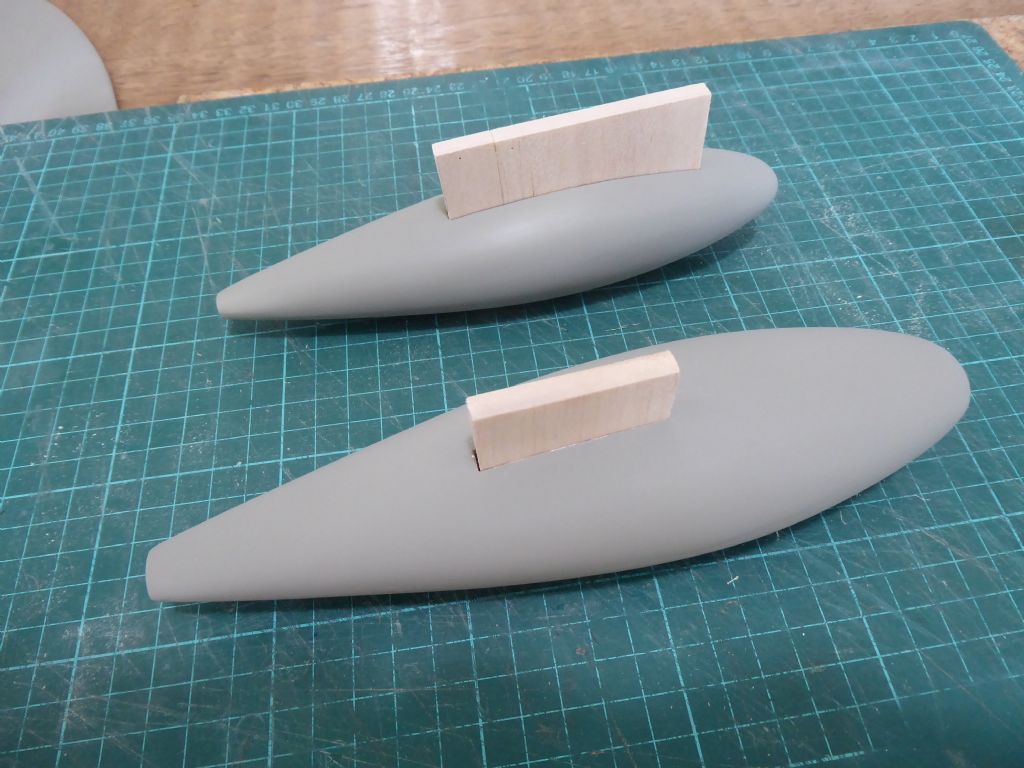

Quite a lot of work is going on "off" the boat. Rig, keel, etc but now I have got to the stage where I need the lead bulb ready so that I can finish the fin.

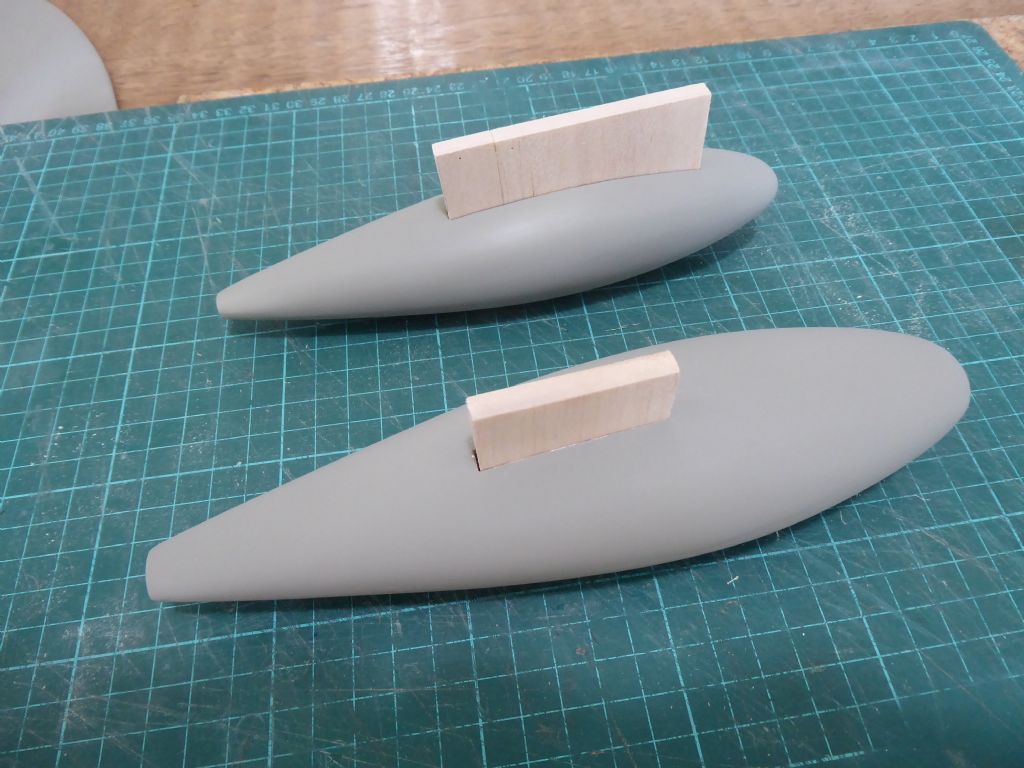

The bulbs will be made with the slots cast in. Another project has a similar but lighter bulb and it is easier and quicker to work on the two in parallel. In the foreground is the Galileo bulb pattern and I know the position of the bulb in relation to the fin to get the cg in the right position because it was calculated earlier. I don't know where the cg needs to be yet on the smaller bulb so the slot will be longer to make it adjustable.

The balsa inserts are called core prints and I will explain later how they work. A quick blast of primer and a good waxing and they are ready to go.

Tim R