If you remember my keel. it is quite heavy, strong enough but strangely fragile and liable to surface damage from knocks and scratches.

This is what it looked like and I found myself moving it around all over the place trying to find a safe haven. My IOM keel is safely behind the telly and seeing as no one does any dusting around there it is quite safe.

Time to make a box for storage and especially transport. It also gave me some breathing space and think time to get back to the deck that had been subjected to a stupidity.

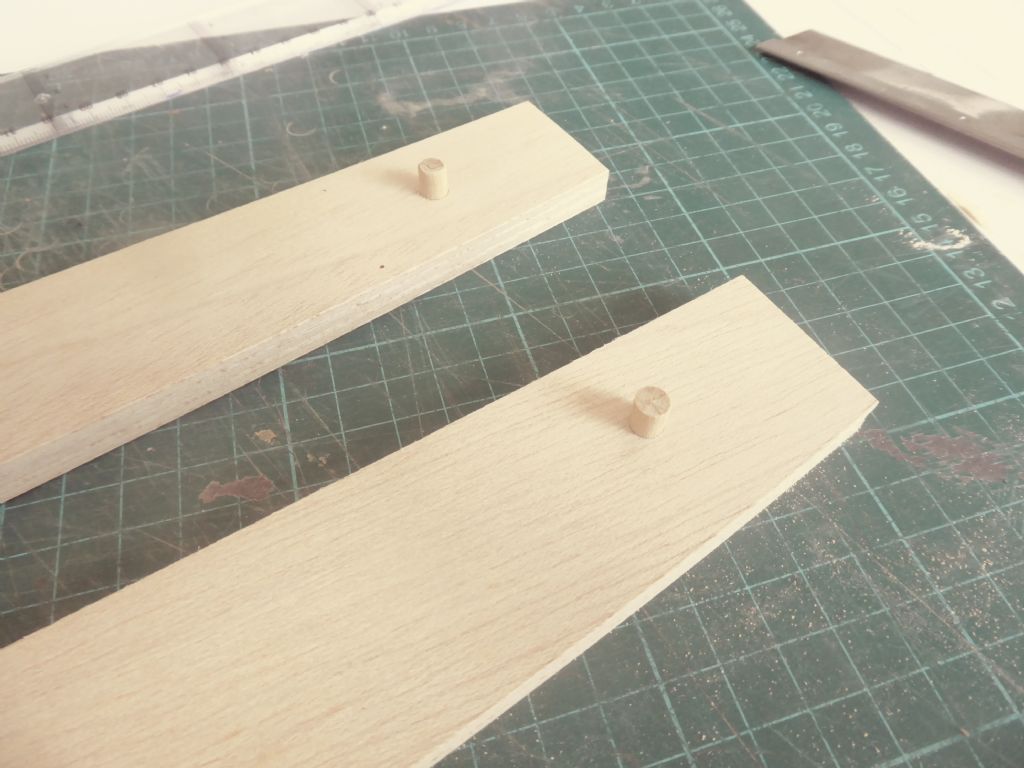

First step was to make the cradle for the bulb. Various bits of balsa from the scrap box glued together and arranged to give the bulb plenty of support.

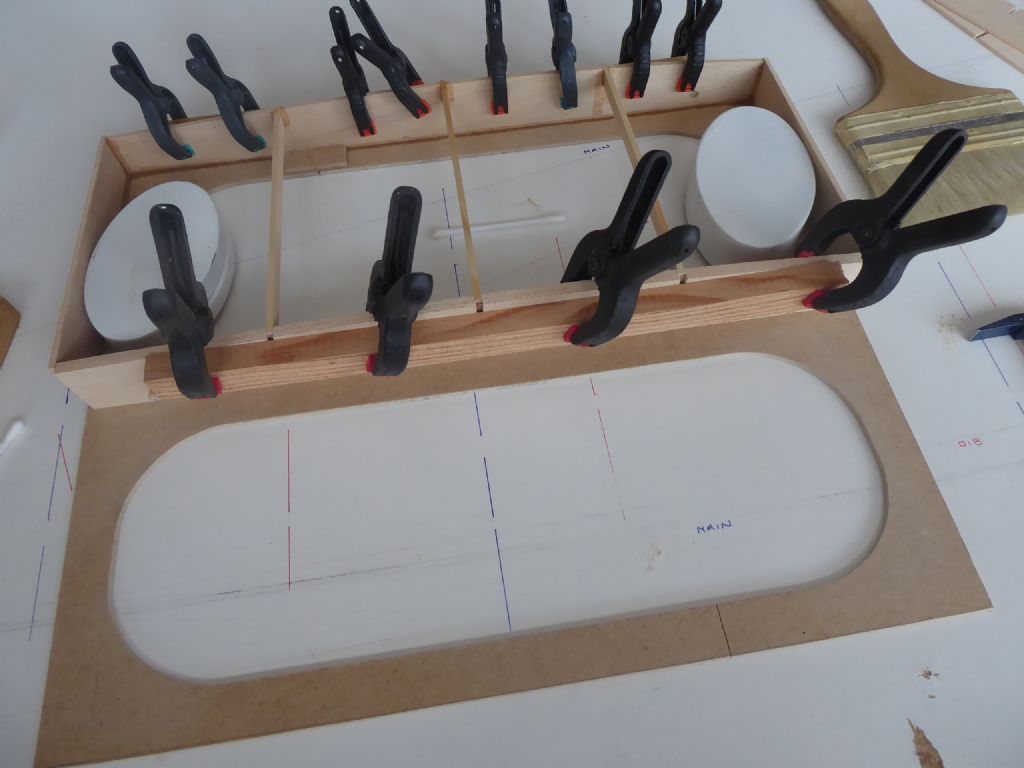

Test fit to make sure the keel was vertical when in the correct position.

Pre-painted and nearly finished with the felt bed.

Felt complete and the sides and base made up. The sides are two pieces of 3mm MDF stuck together with one 3.5mm wider than the other. This make the slot for the slide in cover. The catch is a chromed fitting costing a few cents from a Craft shop.

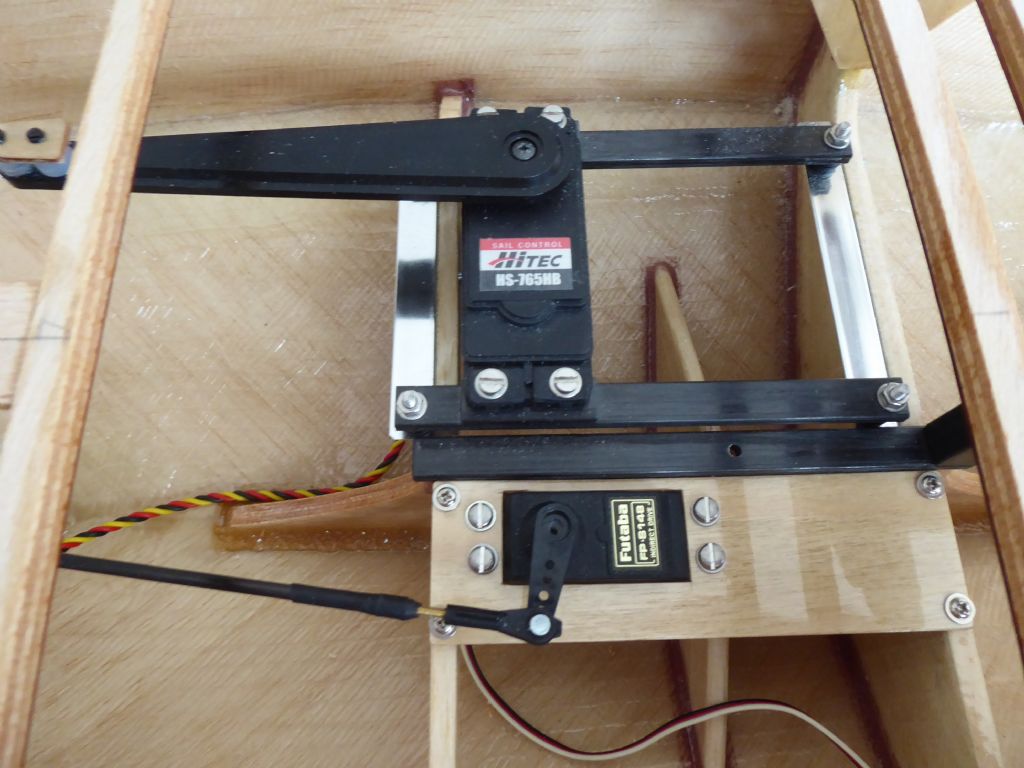

This built-up MDF block locates the alloy tang of the with matching tapers.

Showing the tang in the retainer.

Clamp now fitted to the retainer and the keel cannot go anywhere. The two cross points are M4 machine screws to hold the keel in the boat. One to use and the other in case I lose! The screws are fitted into blind nuts.

The sliding door nearly shut showing the two parts of the clip.

Finished case with pine carry handle hanging on Terylene braided cord. Knots underneath hold the cords in place.

And here is where the keel has been hiding since Novemberish last year. Must have a look.

Tim R