Been awhile since I've done anything on the Fairey builds.

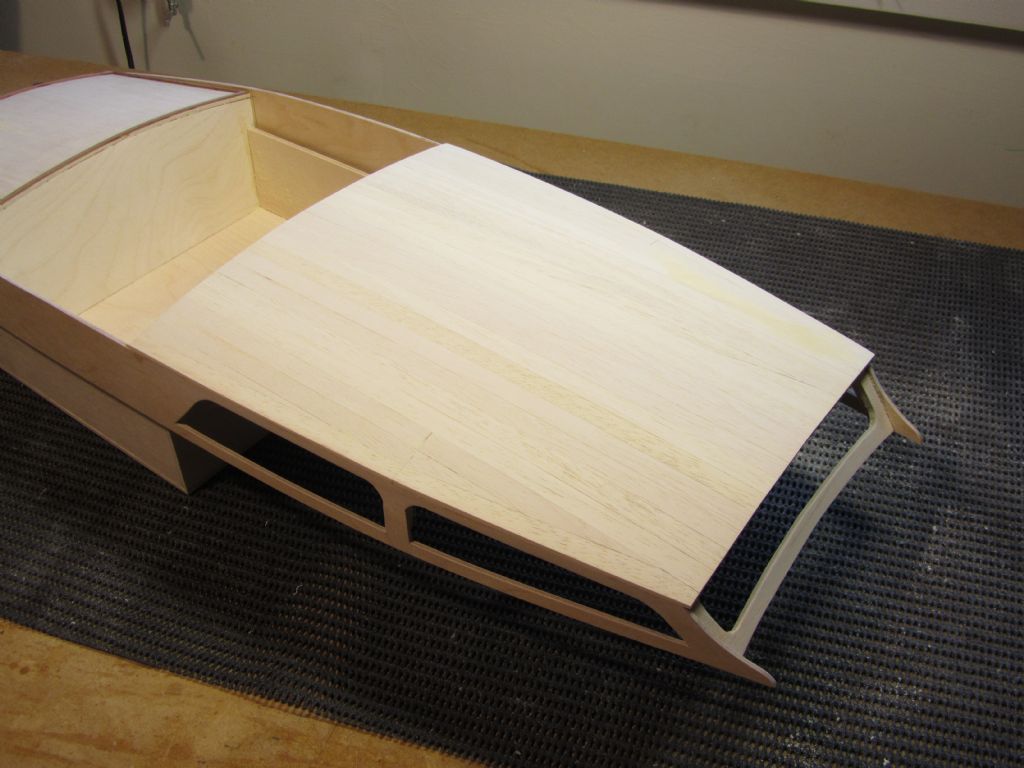

After the last posting I removed the screws, filled the holes with P38, and sanded the chine rails to a more rounded profile but keeping a sharp lower, outside edge, where in the water, to aid turning.

This week I've started fitting the strakes – another of those jobs I'm not too keen on! I've searched on more than one occasion for triangular section timber, but apart from short lengths for dolls houses, you just can't get it. It can be cut with a band saw, but I don't have one, and I've had ideas about using my router to produce the section but the other idea was to use styrene.

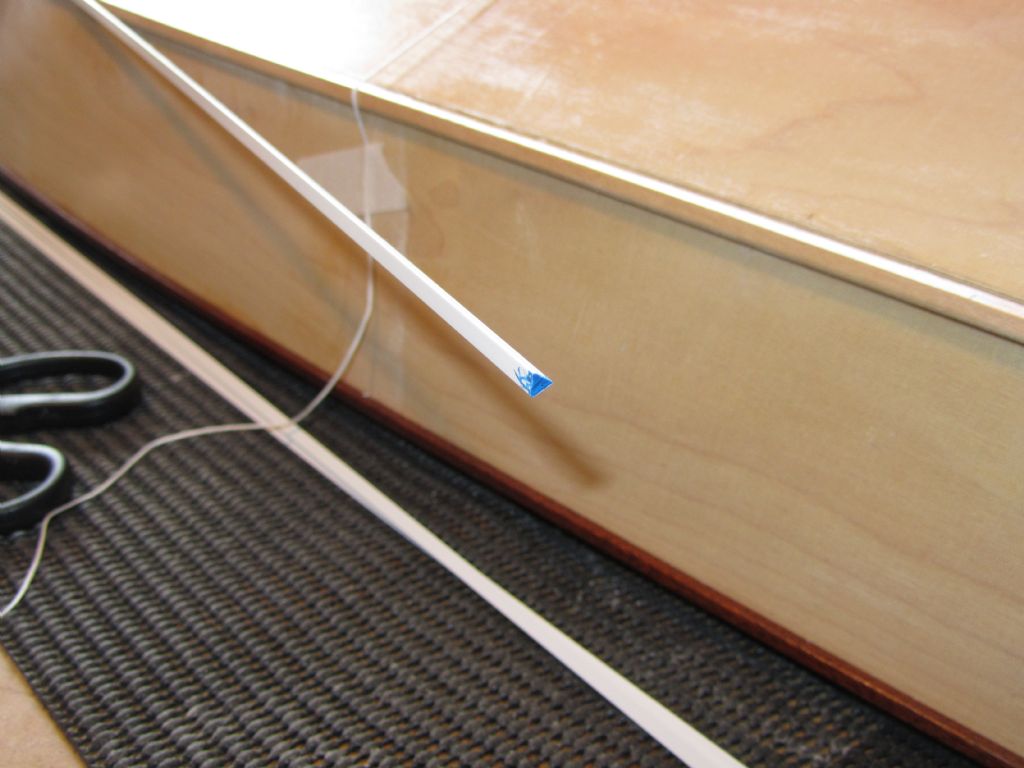

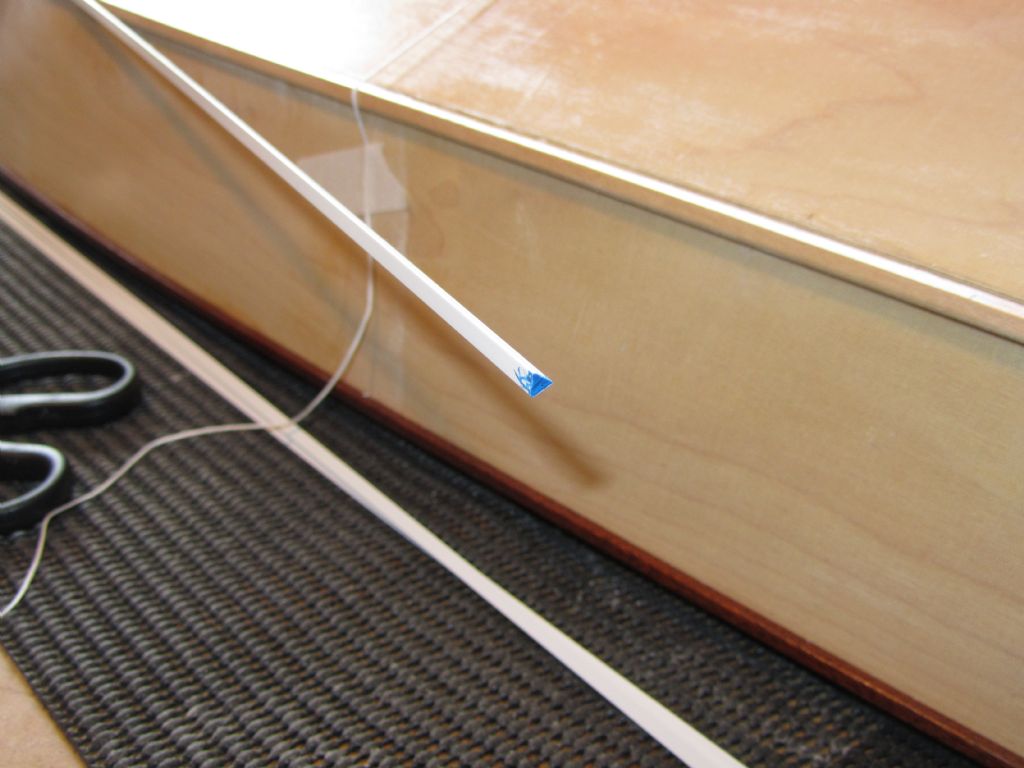

The sections are available in different sizes but finding a stockist of the longer, 1m lengths isn't so easy, but Deans Marine came up trumps. Postage is expensive though, because of the length, but I bought some brass rod for the bow rails etc. at the same time to lessen the pain. I decided on 60 degree 4x4mm for the Swordsman.

What I like about using styrene is that it's a very accurate profile but I was concerned about getting a strong glued joint with the Eze-Kote and cloth. I did a test using Slo Zap slow cure CA but despite being left overnight it pulled off quite easily. Knowing that canopy glue sticks plastic to a number of surfaces I looked up the details and appearing that it would do the job I ordered some from DeLuxe Materials. I then did a test and it provided a very strong bond.

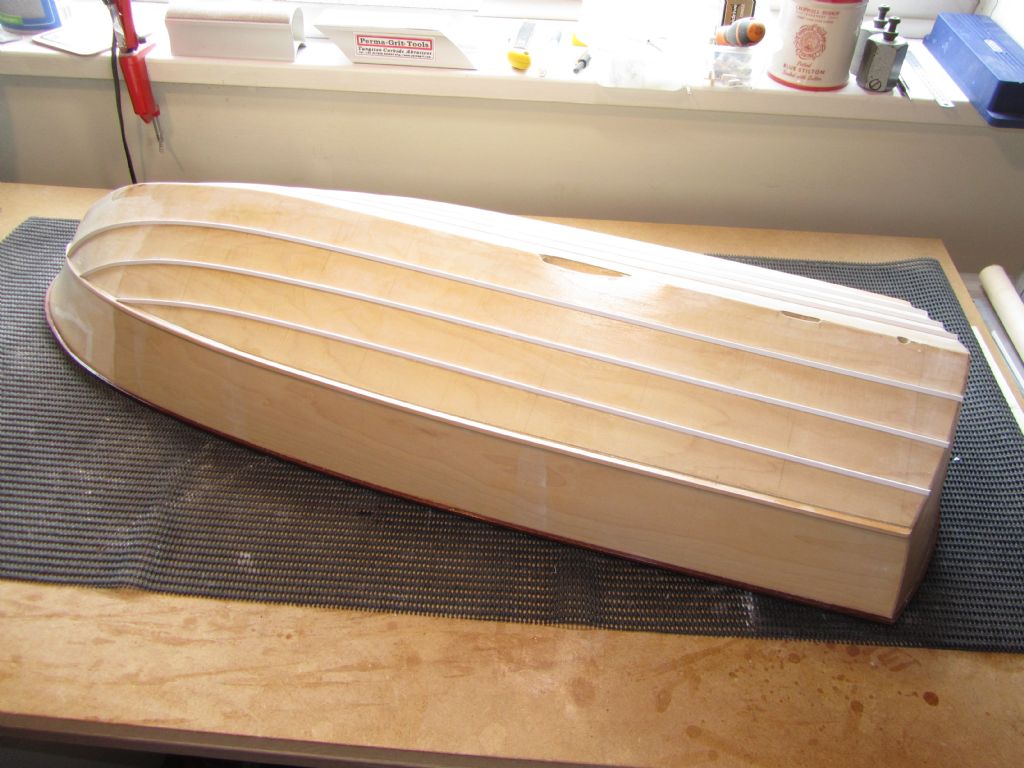

With that good news I could start fixing the strakes. First job was to check the number and position of those on the full-size boat. Fortunately Tireur, which I'm loosely basing my build on only has three strakes per side, though others have more. I then marked the hull up in pencil with the strake positions parallel to the keel and at equi-distance at the widest point i.e. the beam, which looked right.

First strake, nearest the keel, was a bit of a pig. The glue has some grab and dries in about 30 minutes but no way was it going to stick the strake to the curve of the bow. I held it in place for some time and then taped it down and left it for a lot longer than 30 minutes. It partly held, but the end sprang up, but it was enough for me to glue the straight part of the strake which was no problem and once dry held firm. It took me two attempts to glue the bow section with it being held in place with my cork sanding block wedged between it and my scroll saw. Trouble is you just can't clamp it.

I then did its opposite number but lessened the spring by saw cuts on the underside which I will fill with P38. Still some spring but that has been left taped down and fingers crossed it will hold OK.

Then on with the middle strake. When using timber I'd steam it to a bend, but had dismissed this with the styrene. But thought I'd give it a go using my usual steamer, the kettle, and it bent a treat, even easier than timber! B*gger, if only I'd tried it on the first one! But you live and learn.

That was then easily glued and taped in place and will be left for a while before gluing the straight section. A slow process but I will get there. Only another two hulls to do then!

Chris

Edited By Chris Fellows on 11/05/2021 15:41:01

cheap superglue from poundland faired in with lightweight filler.

cheap superglue from poundland faired in with lightweight filler.