well, that was a bit of a struggle.

And as promissed I video'd the split of the first half of the hull to show its release.

The second half came off after I found some leverage points at the bow and stern on the keel…….then it too popped off easily.

And the only damage to the plug was one of the card strips took a little ware and tear, and the anchor hause hole came off from the port side .

However the second side is always a little harder to get off as it doesn't have the first side to lever from…..but that too came off without much of a struggle.

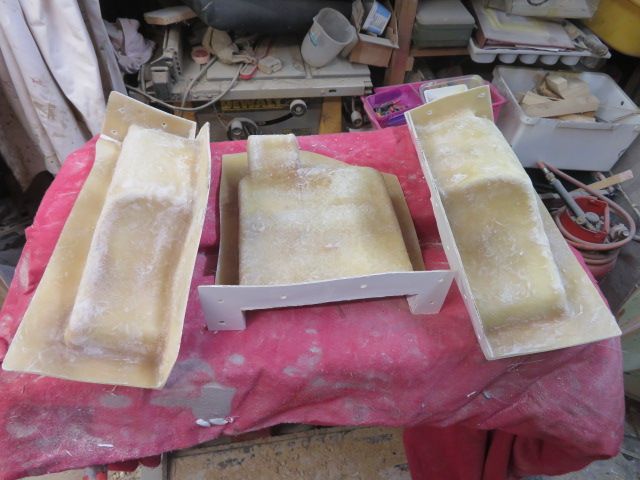

But the splitting of the cabin mould was a little bit more of a problem.

The two rear parts contining the cabin, split and came off the plug easily.

However the front section caused a bit of hard work and the use of two bevel edged chisels to use as "crowbars".

Resin matted moulds will shrink slightly when curing as is to be expected and a well known piece og knowledge.

I thought that I might get away with pulling it off with a little brute force and wedges.

However it really was stuck fast with shrinkage against the walls of the engine casing and the front stand for the companion way, and the only way of getting it off the plug was with more brute force and leverage than just a few wedges.

I had to resort to using two bevel edged chissels, driving them under the flat surface of the grp and the top of the engne casing, and using a lot more leverage than anticipated.

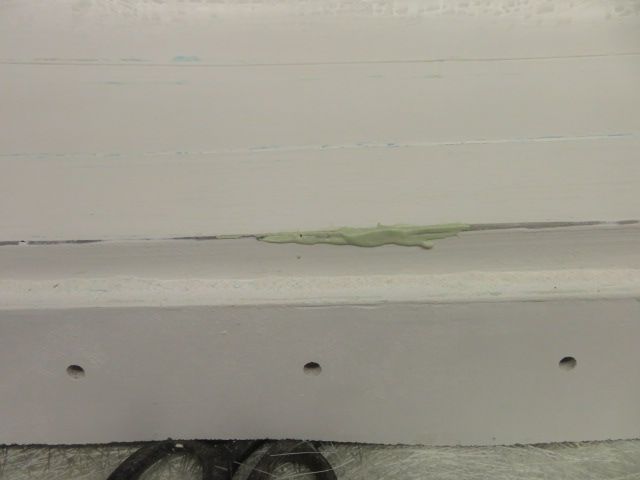

However, with a good bit of effort a lot of leverage, and much swearing and cursing i got the mould to seperate from the plug, with only a very small chip in the flange.THIS I will repair with a small dollop of gelcoat, and sanded smooth.

The good part about the mouldings is, they will also shink slightly upon curing, and I wont have the problem of them sticking inside the moulds……….as it will be they that will have shrunk ever so slightly and will then release easily too.

And then the big question is……..what the hell do I store the hull plug in and where!

(1) Facebook

neil hp.