And then into second gear….

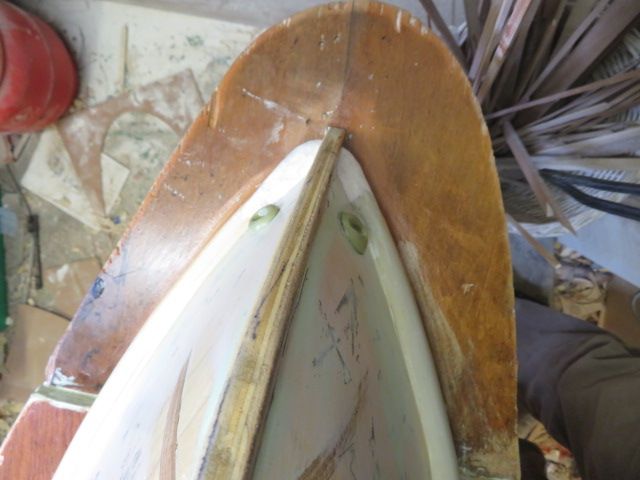

I refitted the wooden blocks that anchor the flange at bow and stern, and screwed the flange to the blocks………not quite a perfect fit, and i have never ever managed a perfect fit, as there are also some gaps between the keelson, stem and stern posts and the flange. But what does one do about the gaps.

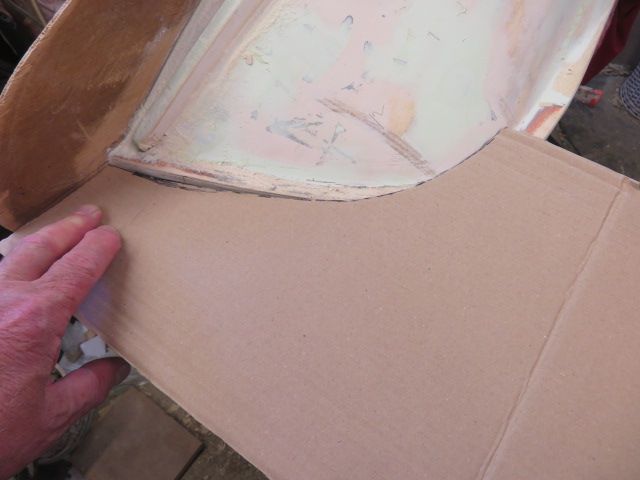

WELL, first of all, the flange has to be held in place so as not to wobble when laying up the first half of the mould., and at nearly 70 inches long on the outer dims, this 5mm flange wobbles in the middle.

Normally with a shorter hull, even up to 46" there isn't a great need to steady the centre as the next process holds a flange in place. However on this length I pinned both the object and obverse side with some fine veneering pins [about 0.5mm diameter] and these did the job holding the flange still and from wobbling. They will be removed from the object side before waxing up, and the holes which will be so small will be filled with the wax that will be added .

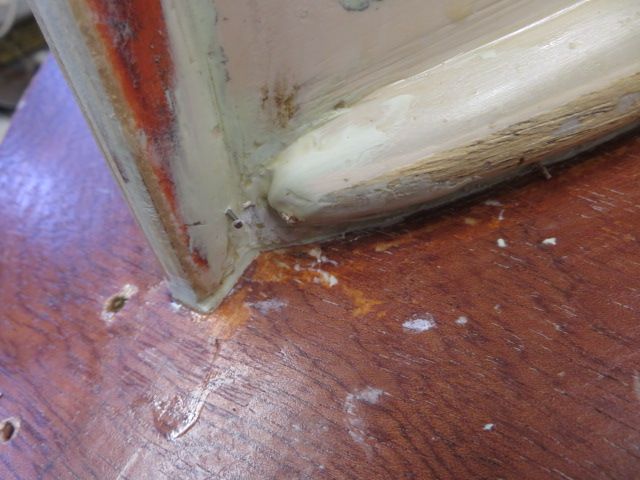

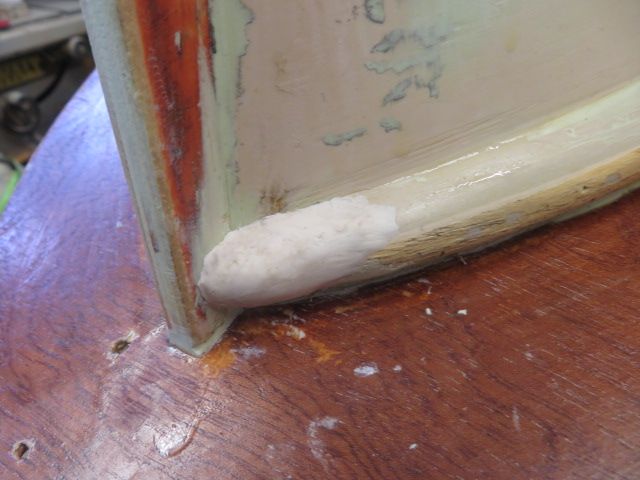

And so the job of securing the flange to the keel began, using at first lumps of nice new whitetac [blutack, black tac or any other combo will do] I stuck the flange and hull together every 20 mmm or so, and then between the lumps of whitetac I stuffeffed into and over the white tac lumps of nicely softened plasticine. [be carefull to use architects modelling plasticine, NOT childrens playdo stuff as the former will go hard after being left and will hold its possition.

Once that is done,………back to the object side and fill all the little gaps with rolled up lengths of plasticine, pressing it in to the gap, with either a chisel, or a thin spatula with a flat end [macdonalds coffee sterers are great for it with a flattened end.

And then its just a case of leaving overnight for it all to go hard, before you start waxing the boat and flange up……..simples!!!

I needed a drink after that, and all I had was a Tango, booohooo!!!

neil hp.