After sanding smooth all of the hollows in the laid up cabins, yesterday I set about readying the insides of the cabin cockpits for detailing.

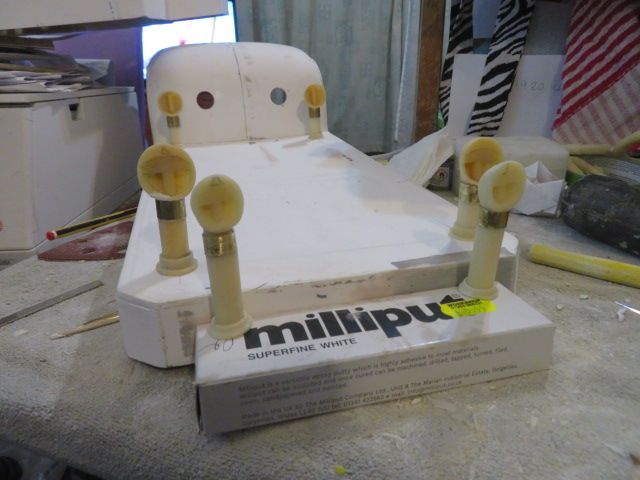

Firstly I made sure that the instrument/access [to the inside of the "engine room" ] on each boat fitted correctly ant marked the outside edges of each structure to the inside of each cabin.

This would allow me to fix the first strakes of the inner framework that would hold together the "planking" making up the actual boats' cockpits.

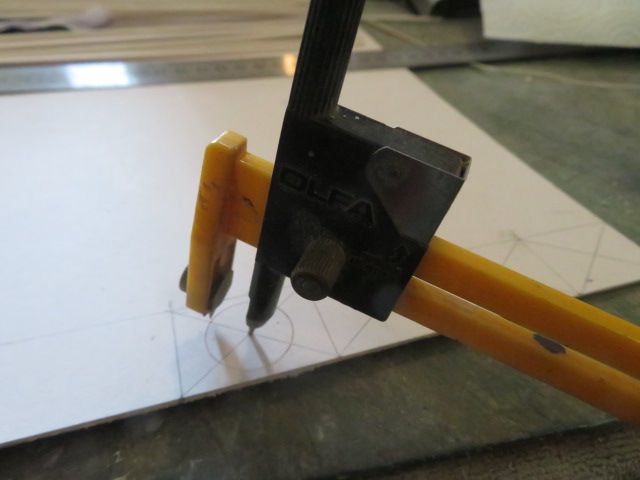

Then the task of marking and cutting the strakes was next.

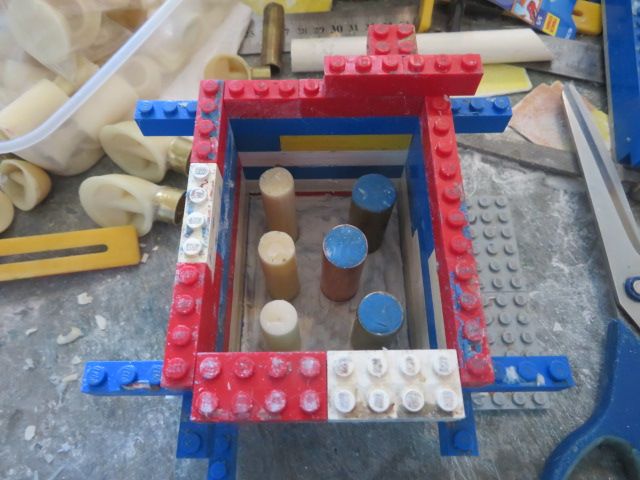

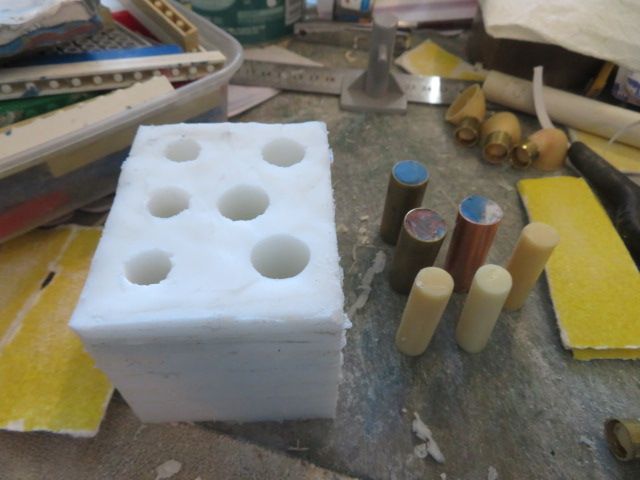

I am NOT a rivet counter, and even on the original Ann Letitia Russell and the Liverpool class prototypes I cheated and made those inner frames from picture framing mounting card, 2mm thick.

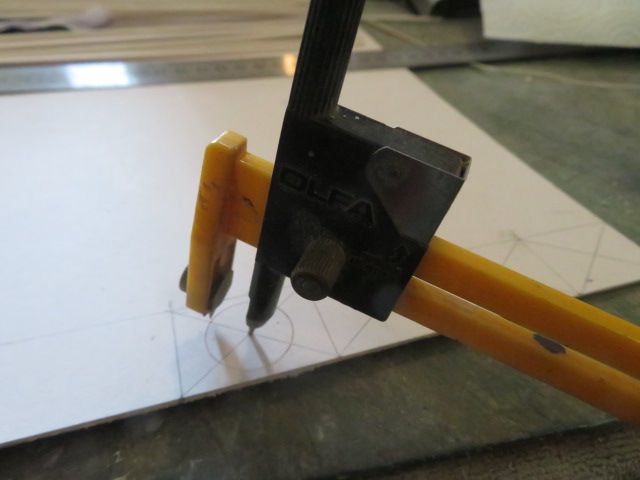

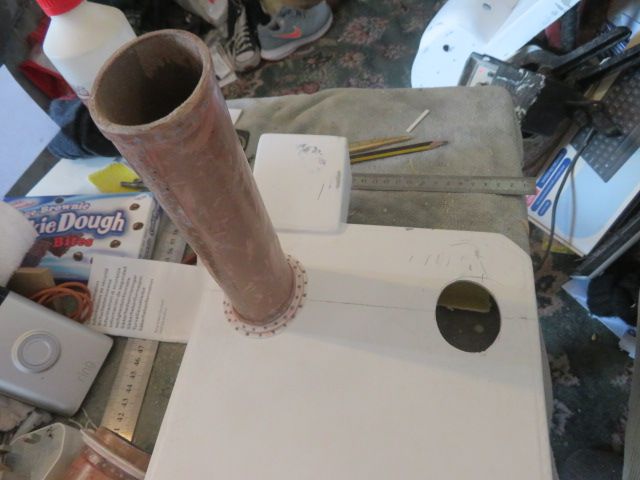

I cut a whole pack of them, 3mm wide last night, and then this afternoon also cut the backing plates for the inside port light closures, that I have cast in resin already. The front port lights have a 20mm dia hole in the centre of the plate, whilst the side lights have an 18mm dia hole, all cut with compass circle cutter.

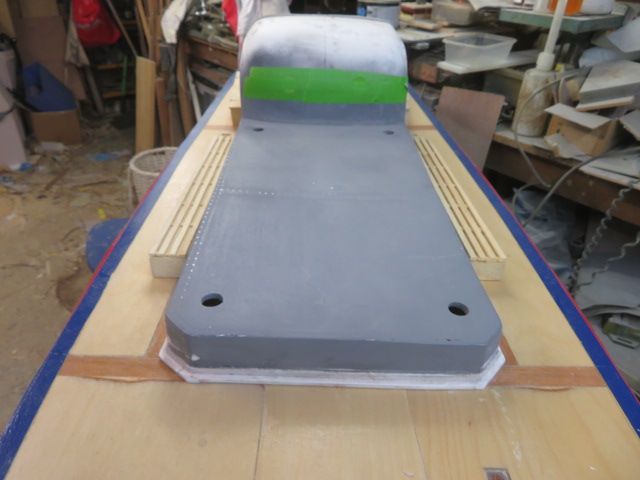

Finally I glued the first frame strake in to the cockpit of the RNLB Princess Mary.

I will leave the card to glue to the GRP Cabin, and then this evening I hope to have the interior of both cabins "decked" out with the full frameworks.

The glue I used for gluing card to GRP is Aliphatic wood glue.

neil hp.