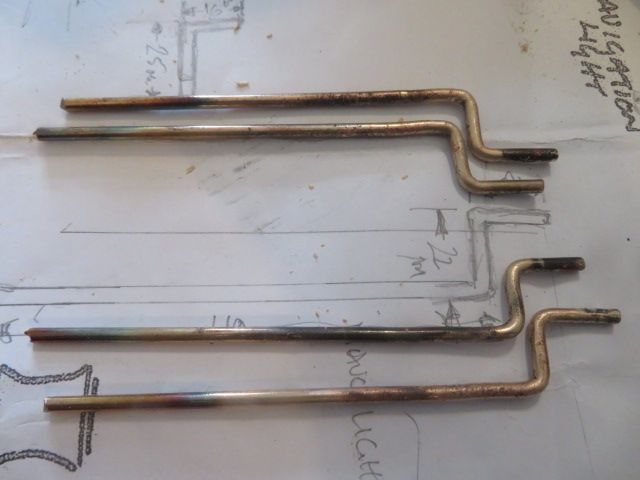

On the final stage of fitting the first rudder, the original wooden one I made for my RNLB Princess Mary, and had proposed to myself that I was going to fit all of the "L" shaped pintols with the leg facing upwards so that I could slip the rudder on to those vertical rods, and to stop the rudders from riding upwards and slipping off the pintols I would put a screw threaded rod in from the bottom skeg and into the rudder……

WHAT A CLOWN I was, thinking that this would work!!!

Having thought about the two points of fixing, I realisedthat the rudder would not have turned as it would have had two points of fulcrum acting against each other in the points of fixing being about 12mm apart, and one would counteract the other .

So I had to think of some other way……..and it came to me during a bloody dream in the middle of the night [we are never far away from modelling even in our sleep……….always thinking of ways to overcome a problem]

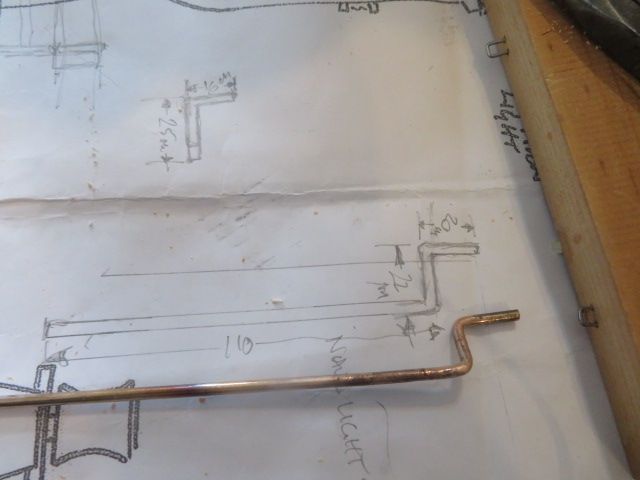

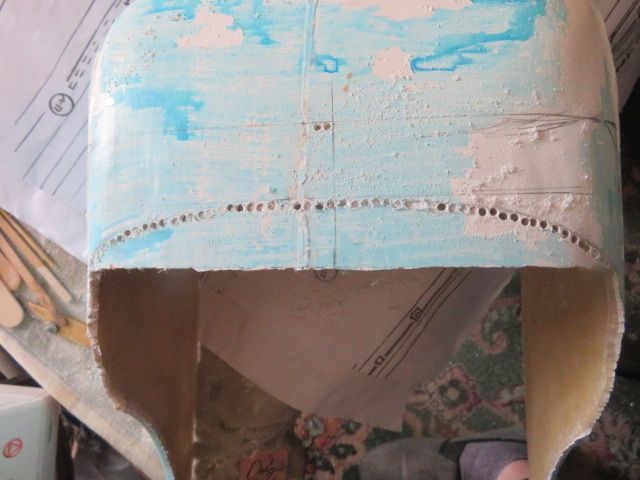

And the solution was so simple. To invert two of the four "L" shaped pintols so as to lock the rudders in to place by the horrizontal fittng rod in to the stern peice,

AND that is what I did, to invert the 1st and 3rd pintols!.

However this meant that I had to fit the rudder now, not later, in order to carry on the build in the order I wanted, but at least when it comes to painting, the rudder will be masked up and sprayed as one unit with the boat.

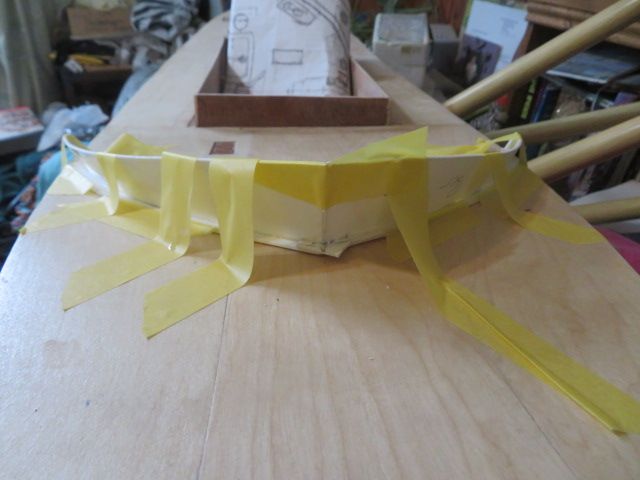

I then put the pintols in place, holding them in position using some plasticine to keep them in the right position, and marking off the pin points for drilling which I did! I used a syring to inject the epoxy into the 4 fixing holes and then fitted the the rudder up to the sternpost and have left it to set for a couple or so hours……….

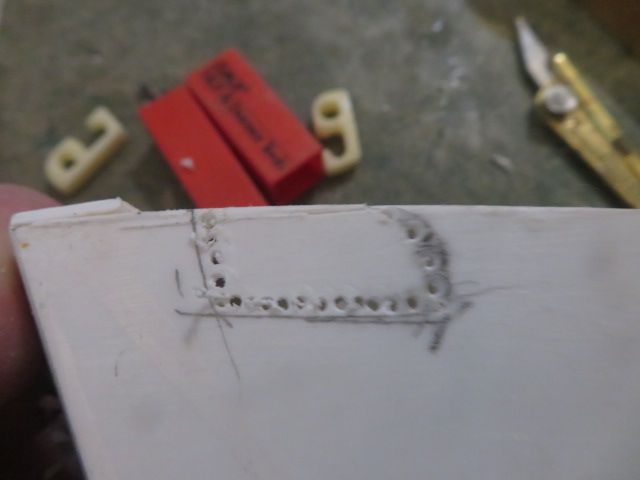

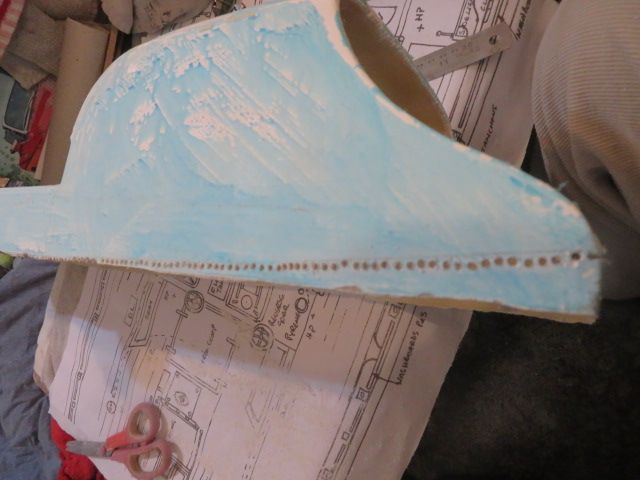

Oh and forgot to say,earlier before gluing AND just to make sure the female parts of the pintols that attach to the rudders stay attached, I drilled with a 0.8mm bit and pinned the pintols to the rudders using fine artists framing pins………..just to make sure everything stays in place 4 pins per bracket were used.

And so, using 20 minute setting 2 part epoxy I have glued the first rudder in place,

And excuse the pun, but the boats are now heading in the right direction, hahaaa!

Original fulcrum points as below, discarded!

neil hp.

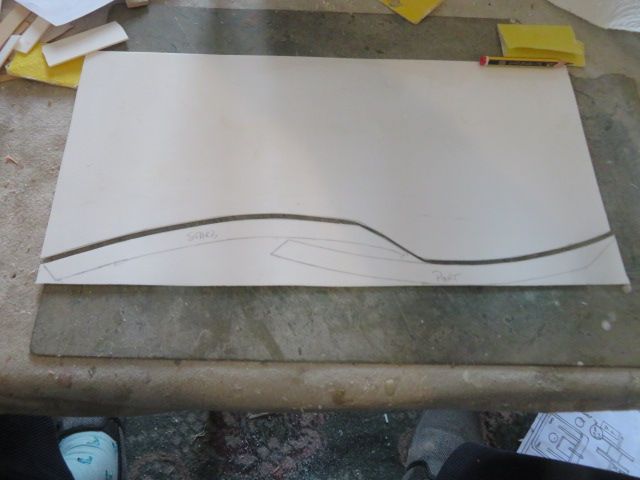

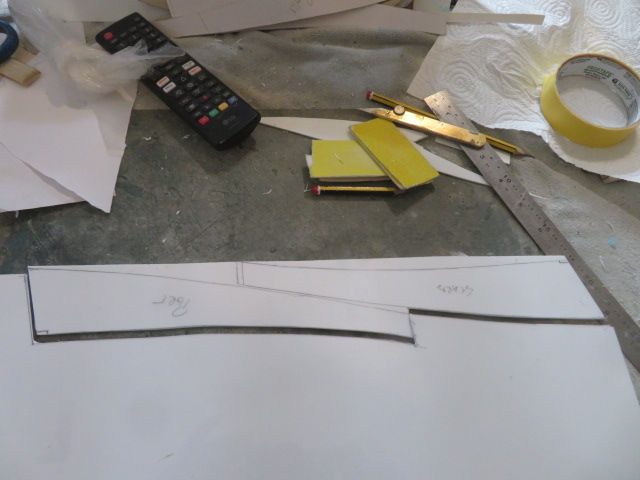

there are very few straight line on boats !!

there are very few straight line on boats !!