Spent about 3 hours this morning sanding the bulwark trim line to the deck, above the belting on the Will and Kate, and then progressed on to the 4 bilge keels, and finally giving the hull its first sanding with 80 grit to remove all of the dimples left by the pva release agent [ the blue stuff on the cabins] after moulding.

The PVA isn't as good as it used to be, anymore, as it dries in streaks and blotches, leaving impressions in the gelcoat, and have decided that if I were to make anymore moulds, I would just add an extra couple of coats of none silicon based wax instead of release agent……saves time rubbing down.

ANYWAY! the first hull is ready for sanding next wih 280 grit carburundum paper, used dry, and then a final sanding of a fine abrasive wet and dry paper, USED DRY.

But as my right arm, hand and shoulder are now aching like hell, I will leave Princess Mary for its bilges and hull to be sanded till later today, or even tomorrow, as the bilge keels have been worked on already a few weeks ago, cutting down time.

But now, at least I am on top of it all, instead of procrastinating and not going in to my workshop.

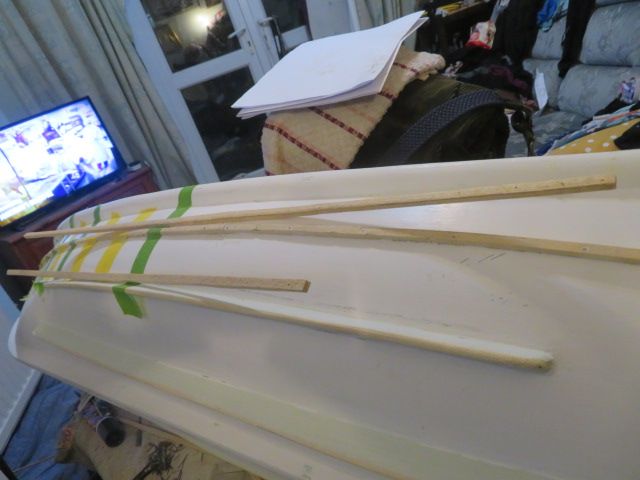

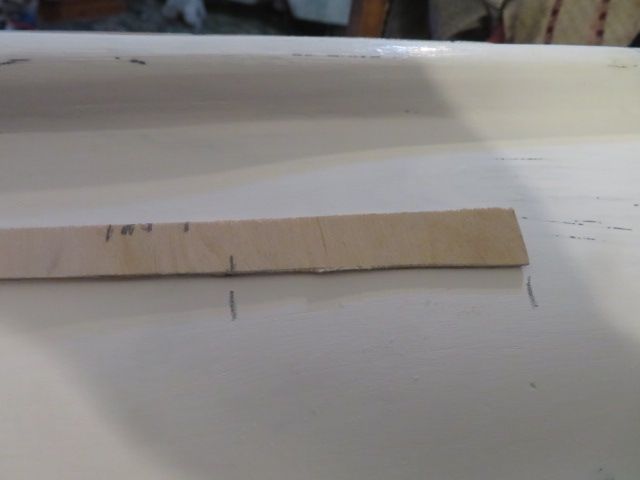

I ALSO have started cutting some timber [obeshe'] ready for adding the above waterline belting extra to the main hull belting, and which I forgot to add to the plug before moulding it all in the first place…………whatta mistaka to makeaa!!!

neil hp.