I must have MUG tatoed on my forhead, but people see me coming!

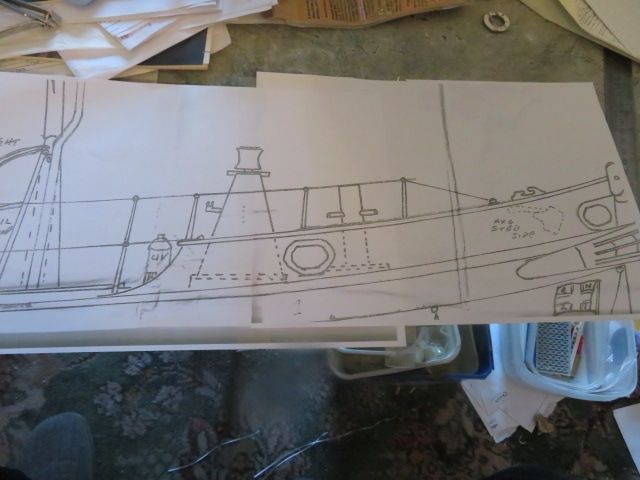

Was asked nearly 6 months ago if I could sort a friends jet drives out on his MBD Shannon……..so went round and had a look………..It was still sunny and warm/.

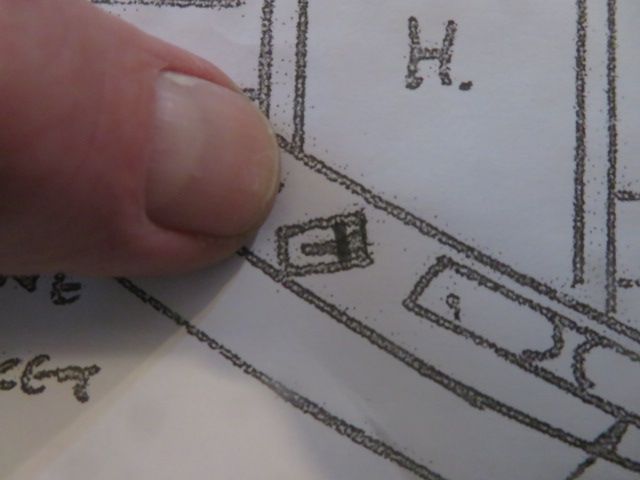

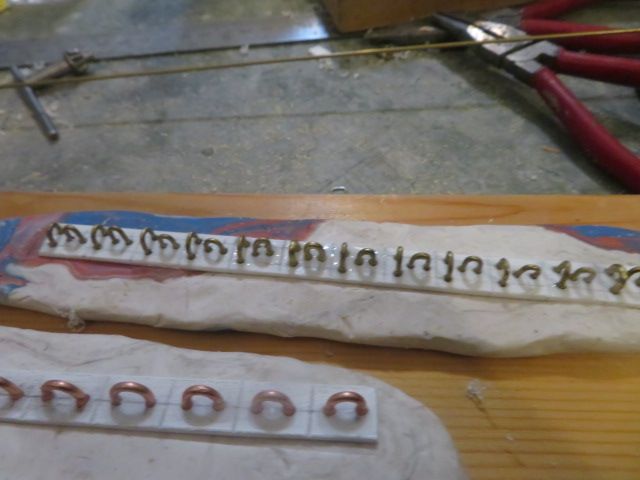

Told him to get rid of the brass rods between the servos and the KMB buckets, that seemed to be broken the buckets And buy some aeroplane "snakes". all quiet for two months, then a call can you come and look at it as I've been told you can buy better looking buckets……..so off I go!

That was 3.5 months ago……..the brass rod still in place but the snakes were there…….which I showed him how to order on ebay.

Can you have a look and see what I can order……….so on to the internet and found what I was looking for…………there you are……..just order them………can you and I'll pay you back…………..NO! YOU order them and if they are wrong, then you can send them back……..

10 days later………….can you come round as I cant remember my passwod to get on………….

An hour later we had found his passwords and ordered them.

9.5 weeks and a lot of moaning because they hadn't arrived within 2 weeks from Hong Kong later and I picked everything up!

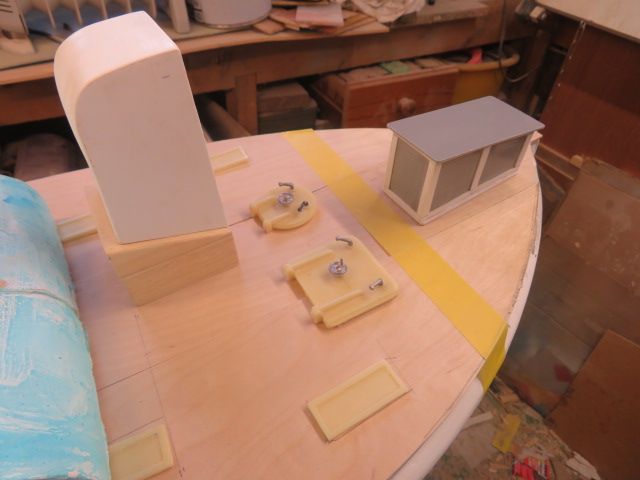

Three days later, and a lot of progress I hope to have it ready tomorrow,…….. day four!

I HATE MODEL SHANNONS, AND JET DRIVES, with a passion……..as nothing fits universally, and EVERYTHING needs to be worked on and adjusted to fit!!!

please someone put my name forward for a humane society medal.

neil hp.