So!!!, you want to make some simple moulds….well here are two types……the surface poured, and the split moulds.

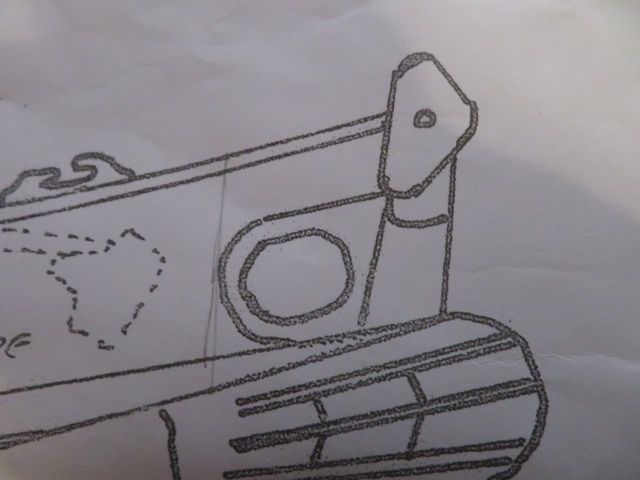

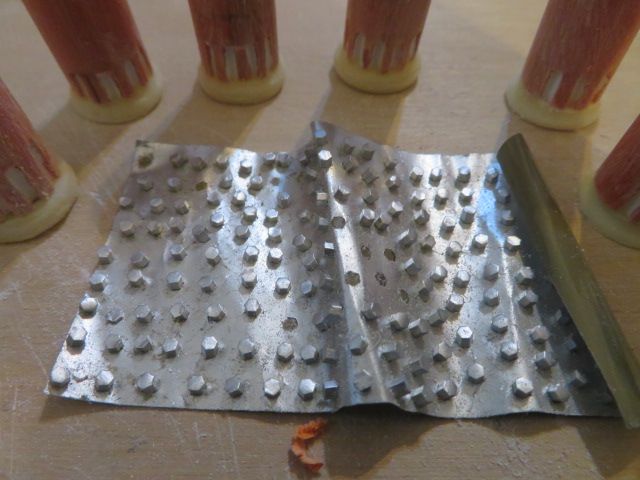

The surface mould can be used when the item is a simple item such as the vent where it has a base and all other parts have a 360 easy shape to copy without any items sticking out, or have a hole in them. As such the base is mounted on a sheat of modelling plasticine, and a box built around it. Rubber is poured in to the box, surrounding and burying the item. Once set the box [I use Lego to construct the boxes] is removed and the "masters" can be removed from the rubber, and then resin can be used to pour into the shapes left by the original masters, thus giving perfect replica's

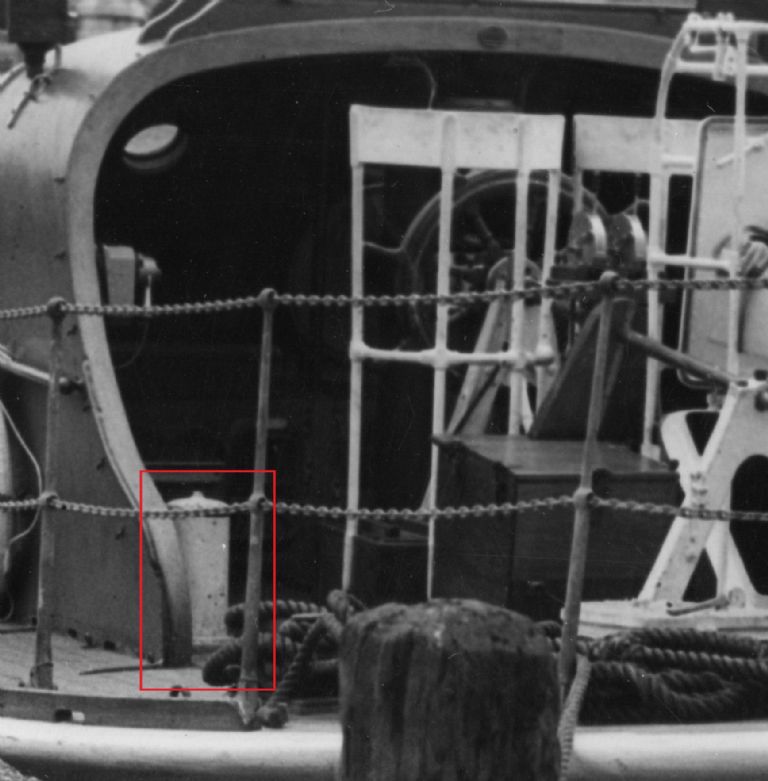

The second type as with the bow "gobeyes", has to be a split mould because of the hole in the centre of the fitting.

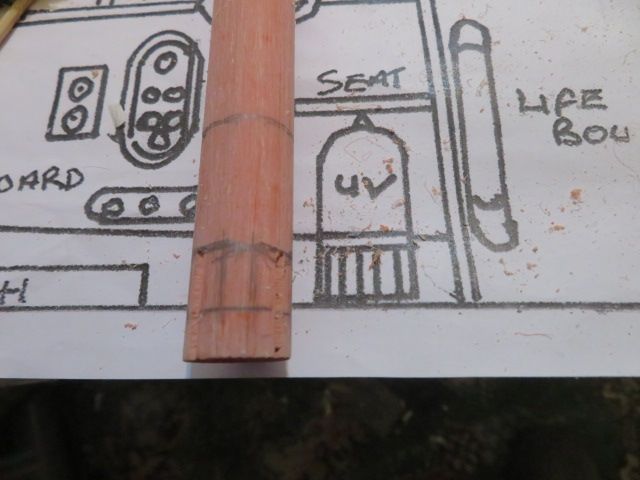

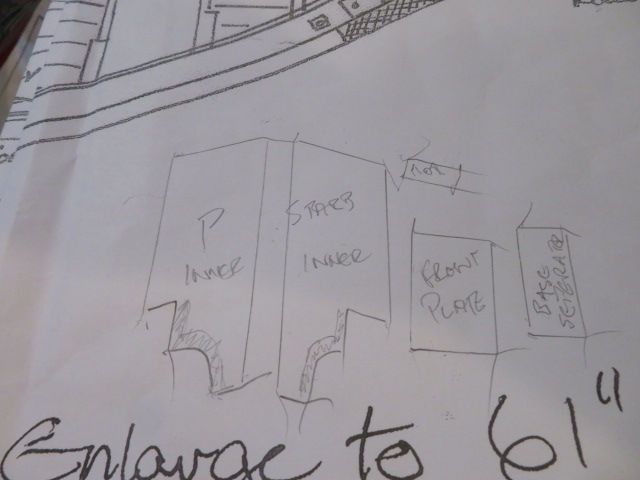

Again a box is made from Lego or material of your choice, and a layer of plasticine is laid into the bottom of the box.

Then the item to be copied is pressed into the plasticine to halfway down its thickness. And once done some indentations are made in the outer rims with the end of a pencil, pen or similar.

Once rubber is poured in to the box, the rubber sinks in to these depressions, thus leaving a "tit" to locate the two halves together perfectly.

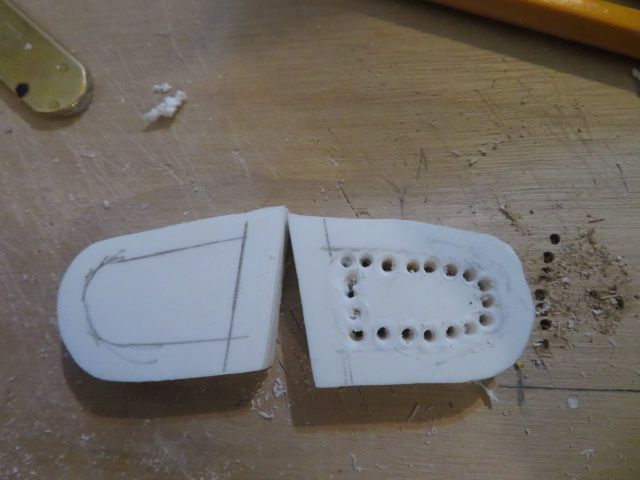

Once set the box can be opened up on the face where the plasticine is, and the plasticine is removed to find the master half stuck in rubber and the other half sitting proud and naked to the elements.

The box is built up again around the second halfe to be cast. But first, one has to put a release agent onto the already existing rubber or when you pour the second half of rubber in to the box, this new half will bond to the first half, and you end up with a block of rubber, with a master set inside that rubber block.

So what do you use as a release agent. WELL, you can buy a can of aerosol release agent from ebay for anything from £8 – 17 quid…….or as suggested to me by one of the men in know at a certain casting suppliers down in Reading, you can rub a little common or garden petrolium jelly[vasciline] or take some ordinary house hold vegitable cooking oil and paint it on to one half with a soft paint bruch at a fraction of the cost of a thumb full of spray from a £10 quid aerosol spray……and that is what i use with perfect results.

And below are the pics in order of the fruits of my labours…..even having cut the flow tracks in the split mould for the resin to flow into.

That split mould is a vert simple one to cast, but on some if there are extrusions from the main body of the item such as a steering wheel where the tongues stick out, one would need breathing tracks cutting n from each tongue to the top of the mould to alow the displacement of trapped are by the resin……..

And its as easy as that.

Go one, have a go…..I find it much more pleasurable thanwriting and printing 3 d images on a machine. But that is a personal choice of mine.

neil hp.