Blackpool Show was a great weekend, due much to the organisation on the thursday and friday of Dave Stav|ros Jones who managed to get all the table possitions for traders and clubs to set out their stalls, and make the setting up on the friday easier for those coming in and out.

Sadly Dave officially retired after the prize giving on Sunday, due to his health and well being, so one hopes that other persons will come forward next year to hopefully do what dave has done for a good number of years to make sure everything runs smoothly over the weekend.

However the show went well and many great models of all kinds, [not just ships] for everyone to feast their eyes on, and some good traders offering show prices.

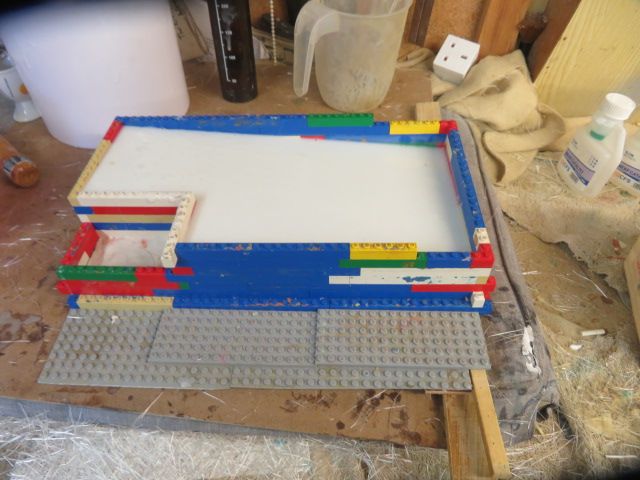

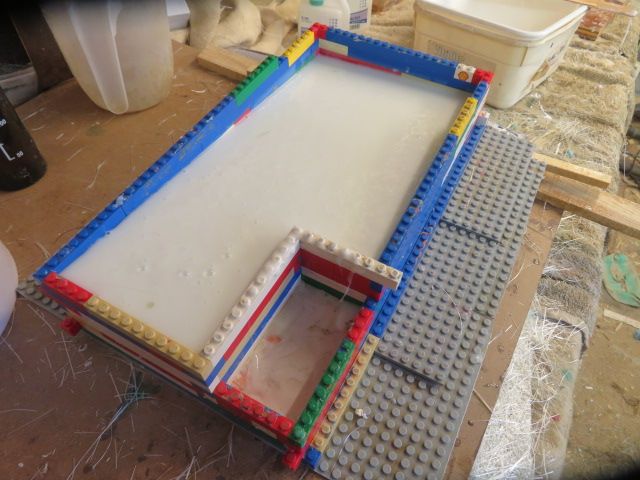

I myself showed the hull and cabin for the RNLB Princess Mary which gained some interest and encouraging comments.

And then i set off to by some supplies to bui;ld mine and one for a friend. SLEC for ply wood and epoxy, Tony Green Steam for supplies of plasticsard. Mike McGough for a box of EMA Plastiweld, Mike Alsop to order a George reign RNLI Flag for the lifeboat, and lastly to Propshop to buy shafts'tubes and 55mm bronze propellers…the only company that i will entertain for my boats props……..they are just beautiful works of art.

And today i started using my plasicard and glue for making some benches and graitings plus companionway covers for the two boats…building has begun again after a weekend of meeting old, new and good friends, models of all kinds mixed with great cake supplied by Martin Kinghoward, all mixed with a great deal of merryment merth and happiness, but also tinged with some amount of personal sadness.

Edited By neil howard-pritchard on 17/10/2022 21:56:25

neil hp.