Its good to see other boats and how they have been made – most welcome

Its good to see other boats and how they have been made – most welcome

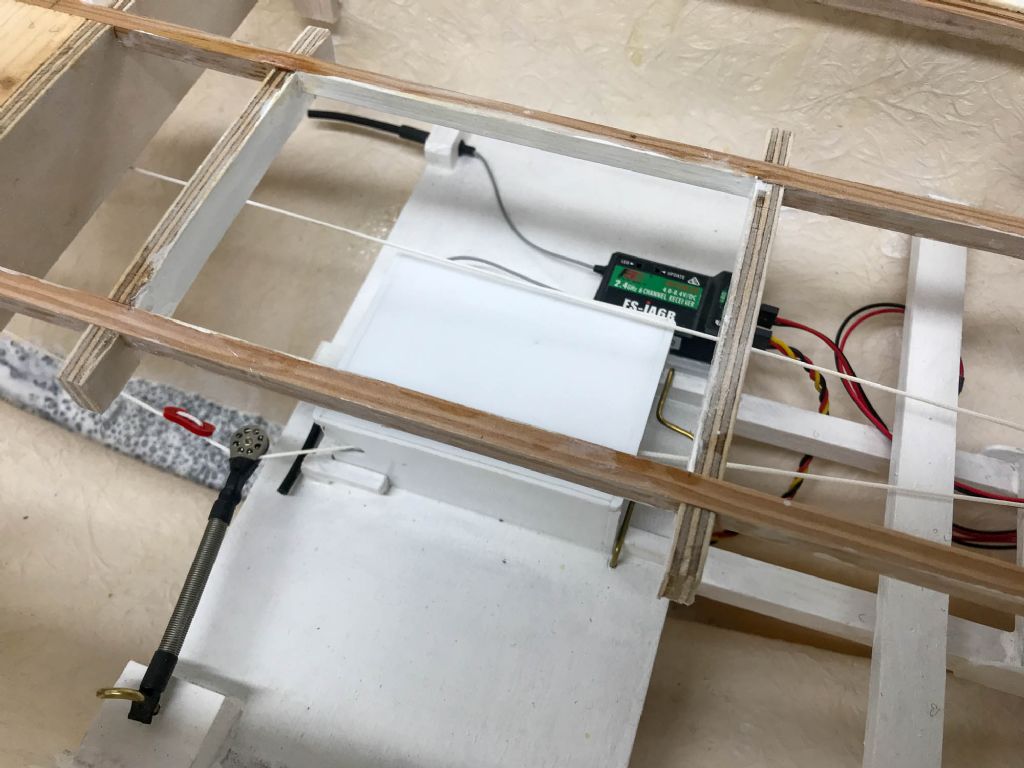

Have added the sail winch and this seems to work, using a spring to keep the loop in tension. Am using a FykySky FS-i6, have set the end points to 70% and this gives around 400mm of travel, which is far greater than the recommended 300mm, so will reduce the end points some more. The plan is to use some bowies on the loop to attach the sheets to. The instructions suggest that the rudder spindle is soldered to the arm, but this seems a little permanent, so have decided to use two lock nuts and some Locktite. The brass arm is also threaded M3.

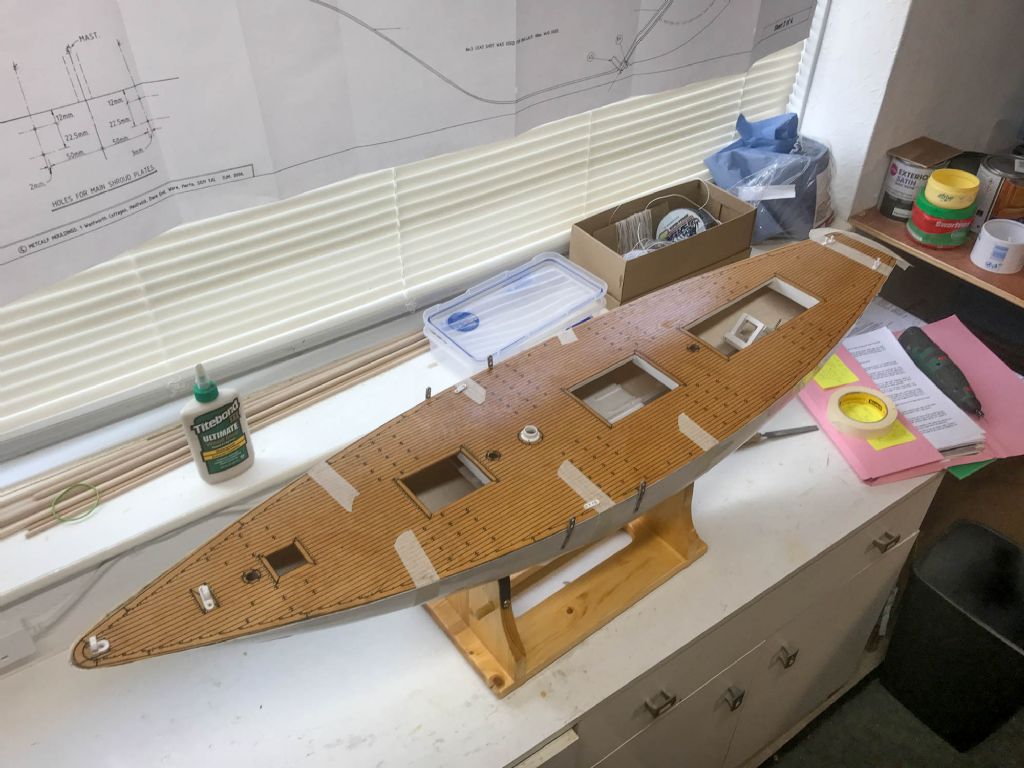

It starting to feel things are getting permanent – as once the deck is on, things become much harder to modify. Have tried a dry fix, using some of the fittings which can be screwed down, helping to hold the deck in place, (along with some tape etc.) while the epoxy sets.

Nothing is permanent yet !