I receive my brand new CNC in 4 days, finally a dream realised.

I will be able to cut parts, carve, and mill aluminium and brass.

I have got the Stepcraft 2/600 with the programmable head.

I also need it for guitar building in the future.

Also considering a 4k mono resin printer in a few weeks.

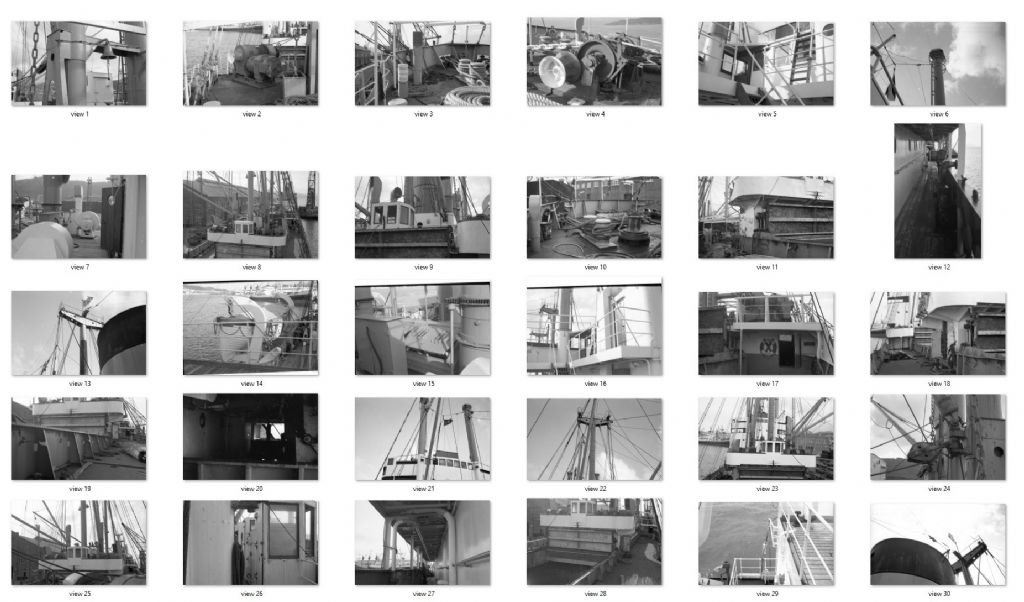

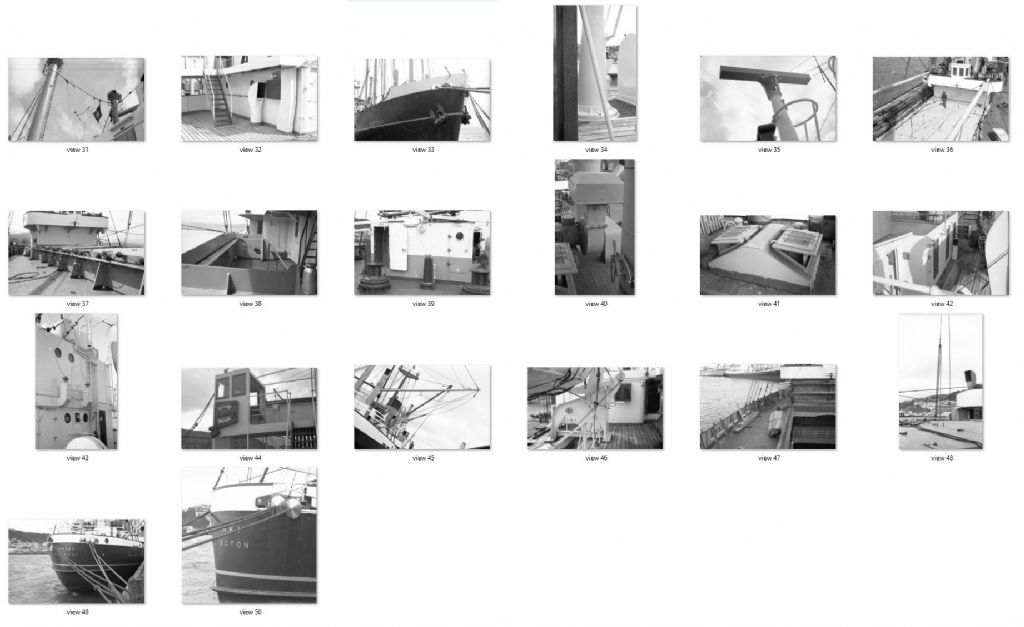

After seeing the result of the KA models 1 /200 Titanic fittings I think it could be a very valuable tool for fittings, and because I have decided to prototype a semi kit of Cutty Sark at 1/48 scale based off my data from the ship I will need both.

I will do a separate build blog for this in due course, once I design the wooden hull structure in cad, however I plan to make it very accurate, I am planning on strong frames at every web frame on the real ship which is about45 frames over the length, why is that needed you might ask, the answer is I want to have accurate planking on hull in 2 woods with the butts in the right locations on every strake so by having every 3rd frame its possible to fit buttstraps in between those frame that locate into notches.

Considering weather to pre taper planks for hull or leave it to builder.

I don't want to build a kit at a small scale as that's been done to death, but I think 1/48 is something most could handle? thoughts on scale?

Edited By Richard H Dunn on 25/06/2021 07:56:22

Edited By Richard H Dunn on 25/06/2021 07:59:44

Edited By Richard H Dunn on 25/06/2021 08:07:02

Edited By Richard H Dunn on 25/06/2021 08:12:43

Edited By Richard H Dunn on 25/06/2021 08:20:56

Ray Wood 3.

Ray Wood 3.