Hi Bob

LOL

No nothing too exotic…it's too dear.

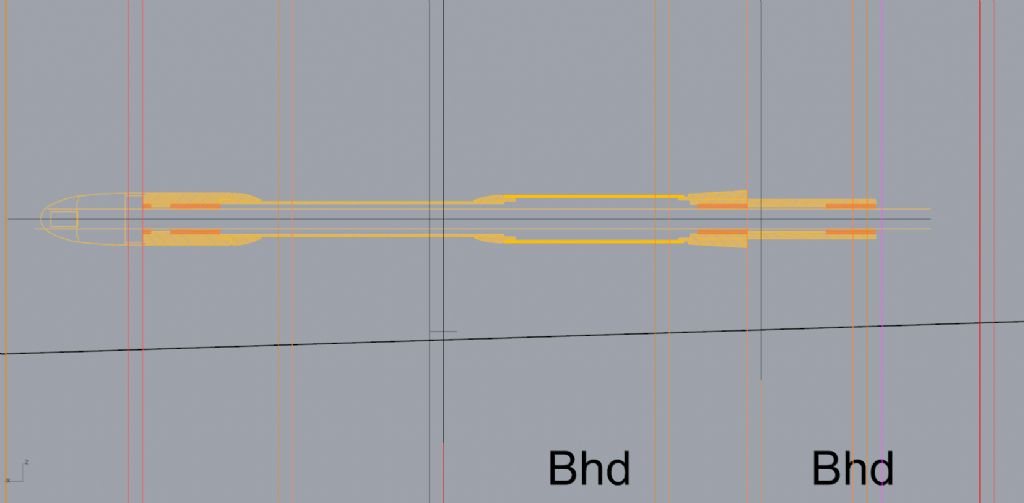

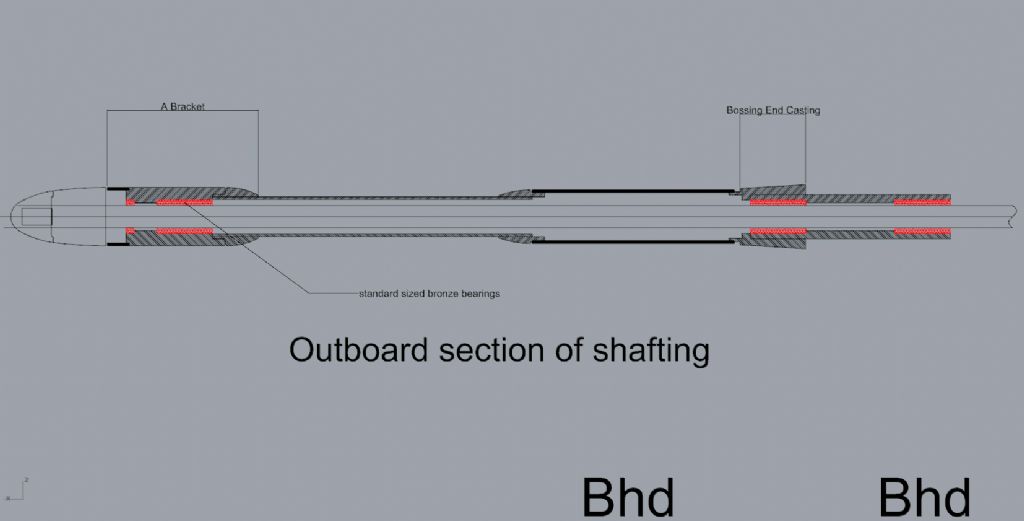

I have not considered seals yet no, just the bearings.

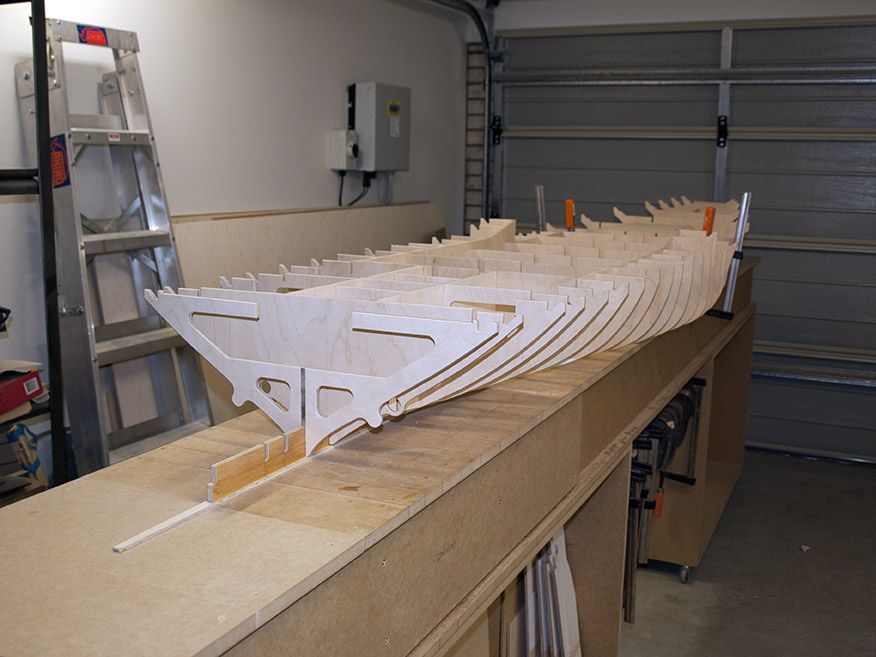

The hull is made from 6.5 mm birch 5 ply with 3.5mm birch ply deck topsides etc.

The lower hull will be planked in western red ceder, it's cheap and nice to work and epoxy really adheres to it well. I have built 3 full size yachts before this way so know it well.

I took delivery of 4 160×20 x 3900mm boards last week that I need to re saw into 3.5 x 6 mm planks.

The rest of the model will be a mixture of techniques,I want to use etching as much as possible, I have never done it but having all the CAD side covered I figure it can't be too difficult to get set up.

I have sourced the resist paper and chemicals already.

I want to use this for all the parts that have openings or the upstands around decks etc as i can then solder or braise the stanchions onto this so it's strong, I also think that using sheet gives a certain rustic realistic feel.

I have used styrene before for models but the problem here is when it gets really hot it distorts and ruins models rather quickly.

Some other parts will be resin castings, another new process, but an easy one ,I intend using for anything that would be too hard to make any other way, anchors ,cowl vents etc.

I intend to fully light the interior as well as navlights etc, I have made preparations for this very early on so it is not too much of a mission , what i have done is allow for a second longitudinal bulkhead behind all surfaces that have ports or windows , this can be used to run wires and also to stop light bleeding from one space into another.

The hull will be glassed with a light weave of some sort and then all the detail added, intakes discharges etc and also the weld seams,I experimented with this a while ago and found that by scoring the primed hull on the seams after its primed to create a small groove and then super gluing a suitable guage wire .3-.4 of a mm is scale for a half inch seam or fishing nylon into gave a very good look and to scale.

Once glued on a rub down to flatten it slightly works well.

I have a full detailed shell expansion so layout is not too hard.

I want to try to replicate the plate ripples as well but very very subtly, I don't want to ruin the hull by going too far.

I considered the technique used in the Book Building a model dreadnought HMS Thunderer but I feel it would be too large a risk gluing copper to the hull, i want to find a way that can be done in the actual coating.

I expect to have the hull and hopefully the superstructures plywood base structure done by the mid next year…..

That's the easy part for me at least.

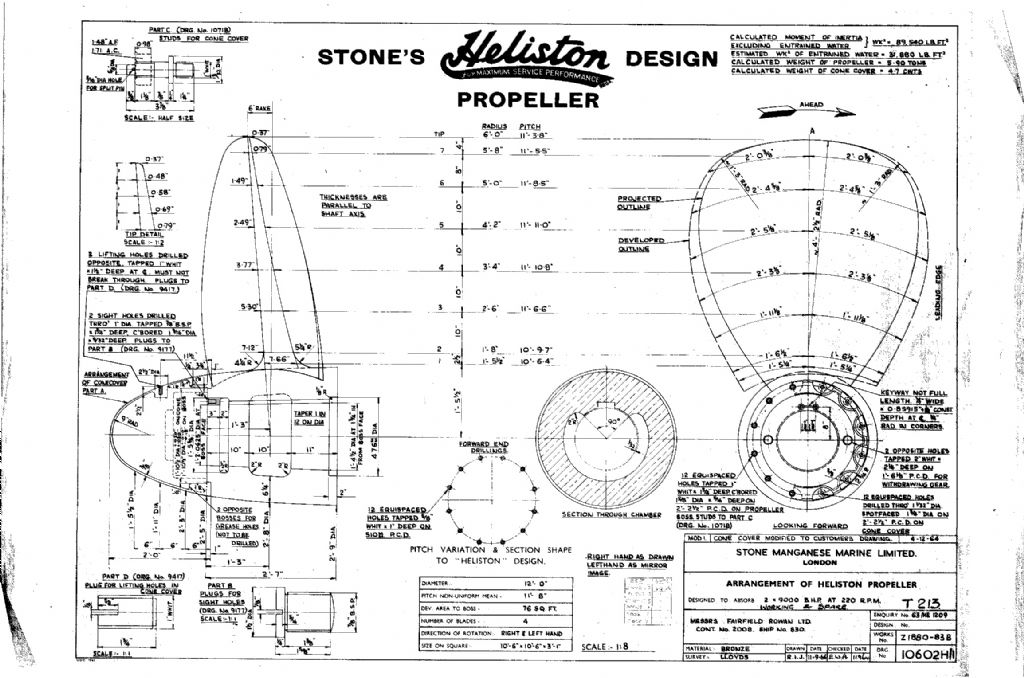

I have emailed Simon at Prop Shop again for a quote.

Edited By Richard Dunn 3 on 03/09/2015 09:16:17

Edited By Richard Dunn 3 on 03/09/2015 09:18:24

Edited By Richard Dunn 3 on 03/09/2015 09:20:06

Ray Wood 3.

Ray Wood 3.