Yes I rang Simon last night.

They are making them custom to the plans , even the little bolts that hold on the nose cone will be on it and working.

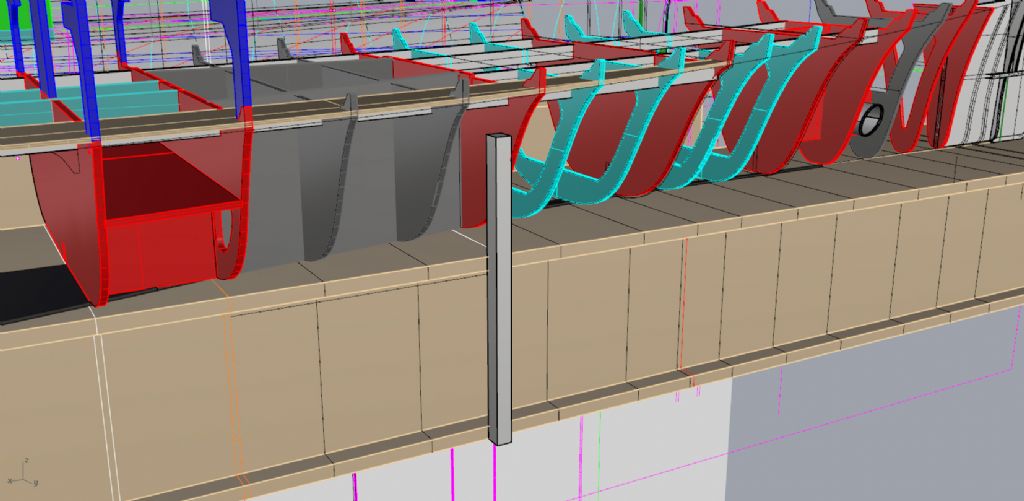

So today just kept framing, I added the sides of the ventilation trunks, the top of which shows the height of the main deck.

The notches in the top are the joining points for the main deck/ hull side frames.

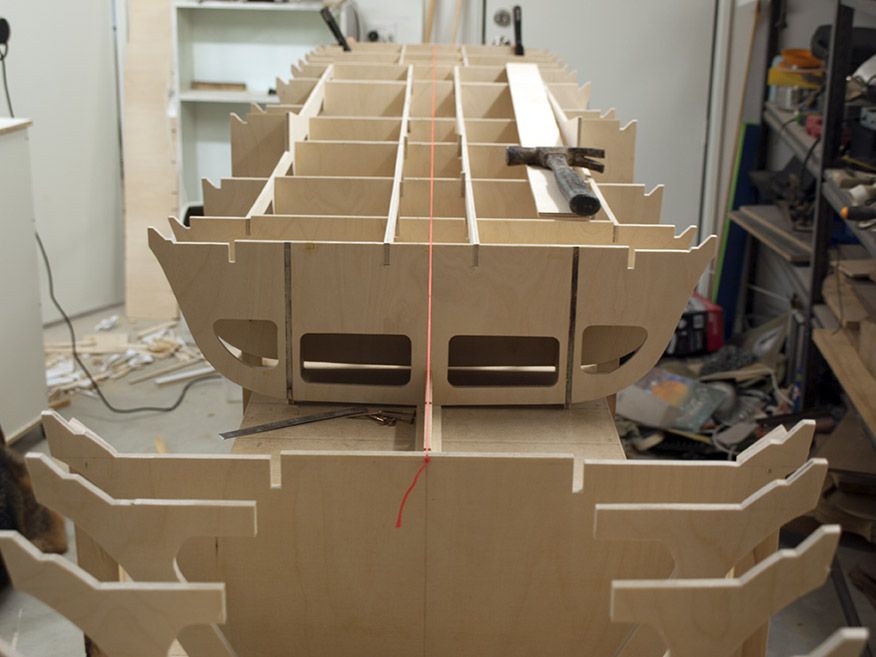

I started finished the bow unit as well minus the solid stem but I will do the after planking.

They are aligned here just loose.

I also had some help testing the fairness of the frames , I am reasonably happy with the result.

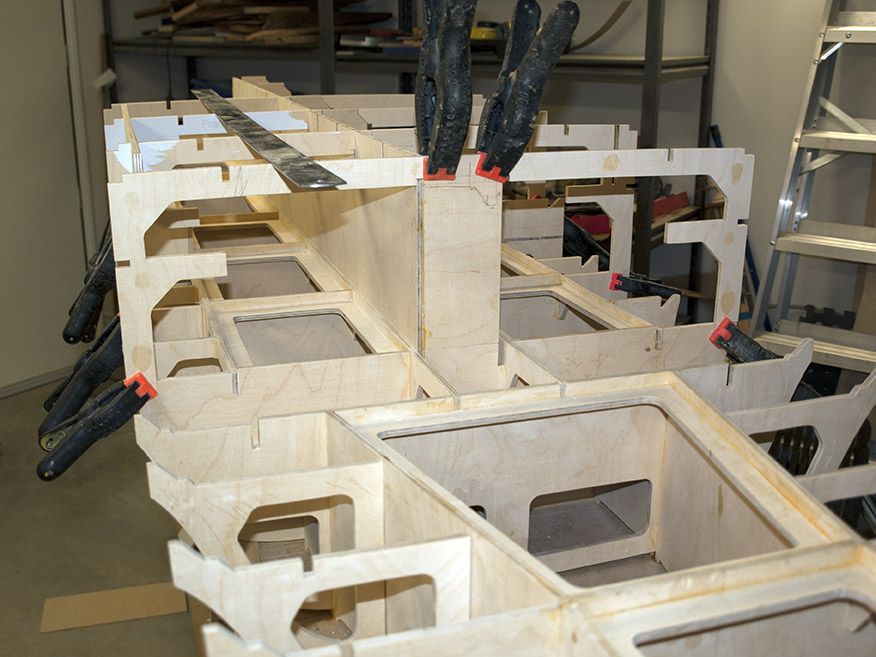

I have also done a close up of a hatch surround and I also decided to use glue blocks in the corners as further reinforcement, I imagine it will also help any glassing to have a less than sharp corner.

This is all the framing will have as well as the deck sides which run up to the girder(the step for the 3.5mm ply can be seen)

I have also started the aft unit and cut out the steering gear flat on the centerline.

Oh and I could not help myself, don't you love it when you look up the shaft holes..and they line up!!!!!

Edited By Richard Dunn 3 on 10/09/2015 08:18:32

Edited By Richard Dunn 3 on 10/09/2015 08:21:26

Ray Wood 3.

Ray Wood 3.