Hi Richard,

I agree with Ray, please reconsider your decision as a lot of people have been really enjoying the build and want to see it continue.

I think the gap in your postings has resulted in people forgetting a lot of the earlier detail in a 30+ page thread going back to 2015 and the recent postings simply zeroed in on your report of lower hull issues in isolation. Hence the comments about wood problems.

I have just spent a while reading through the whole thread again and I think you are wrong in interpreting comments as negative. On the contrary, all the comments on the build from page one have been universally positive and most express sincere admiration for your work.

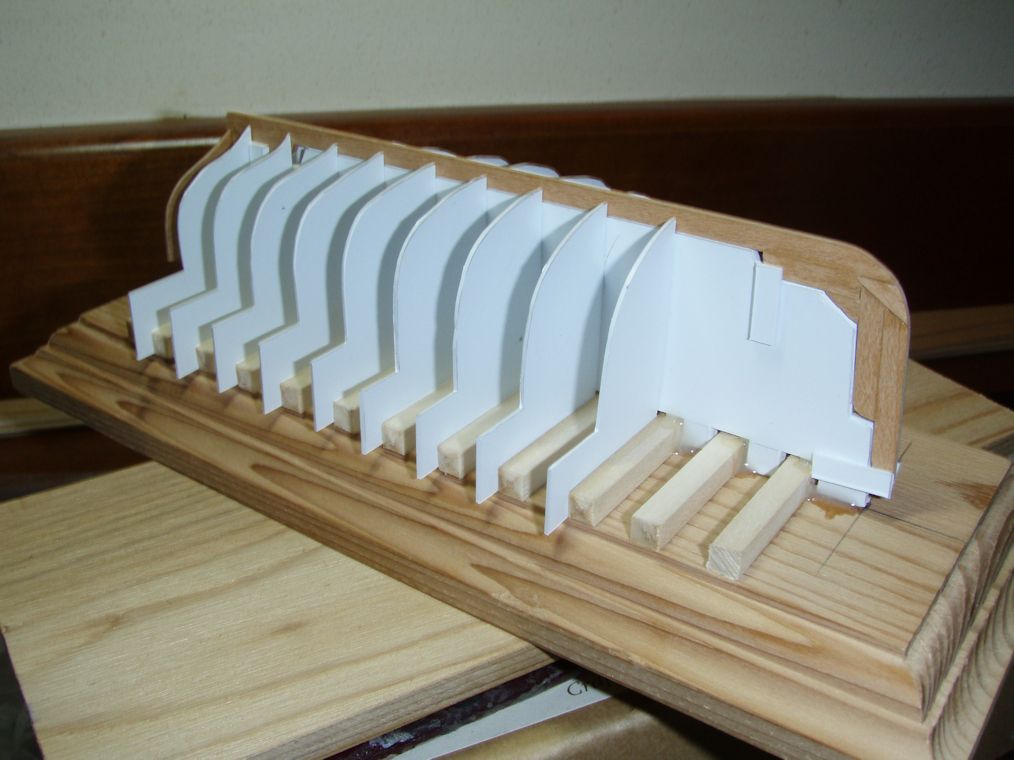

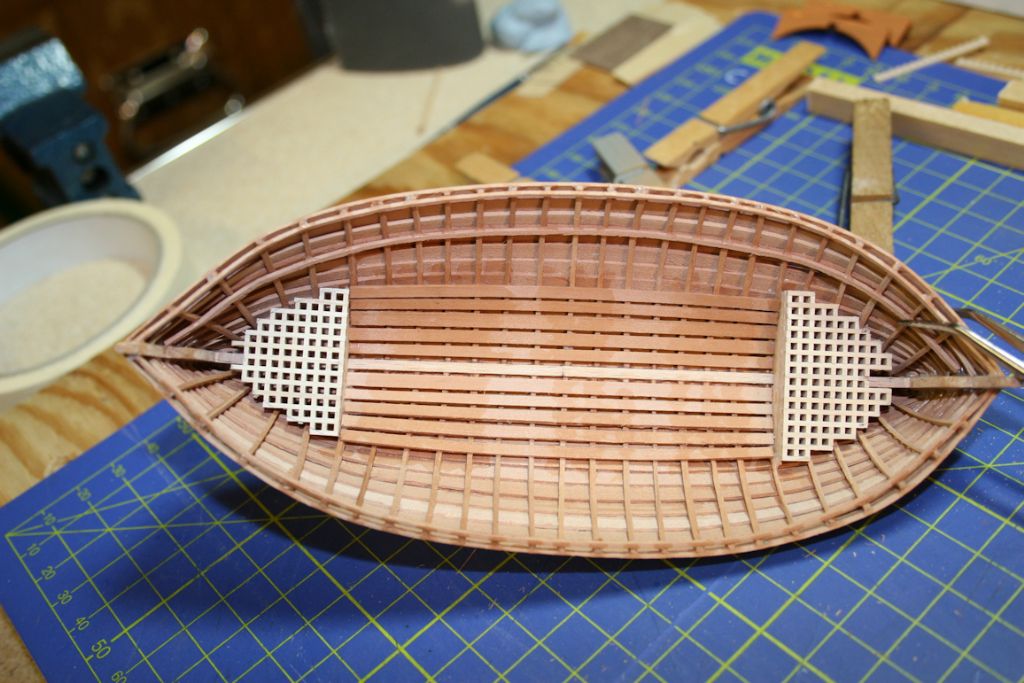

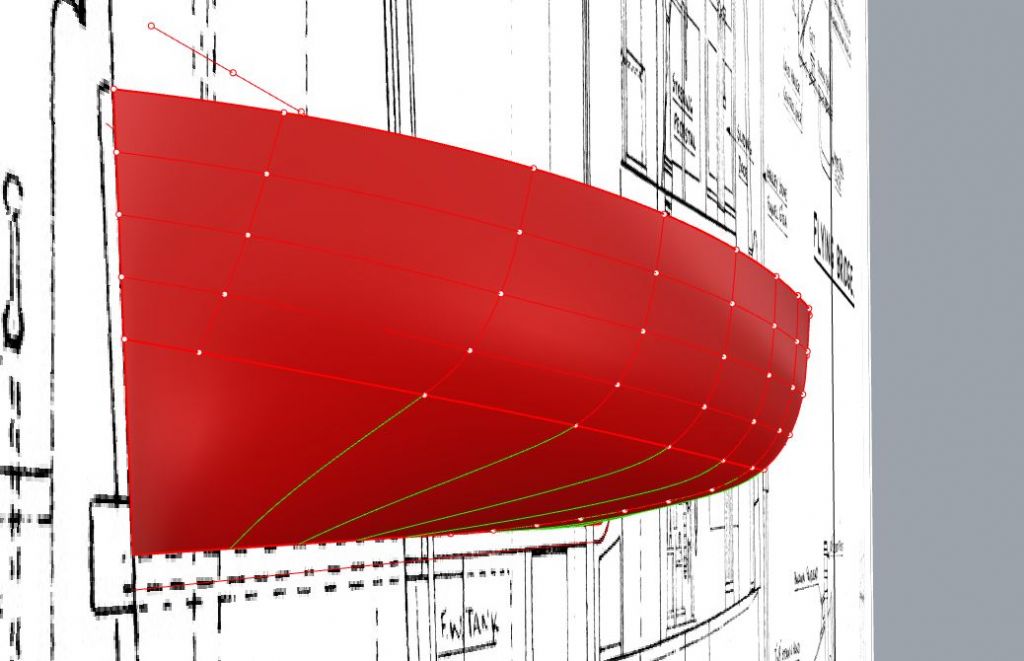

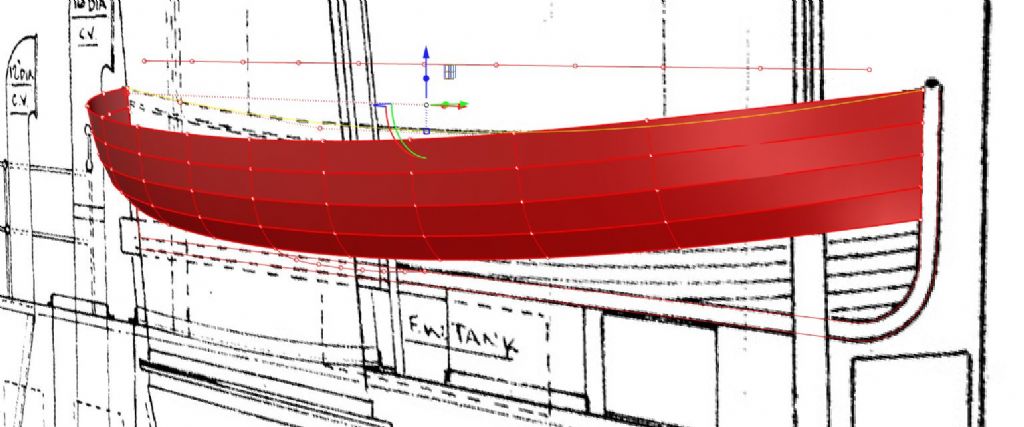

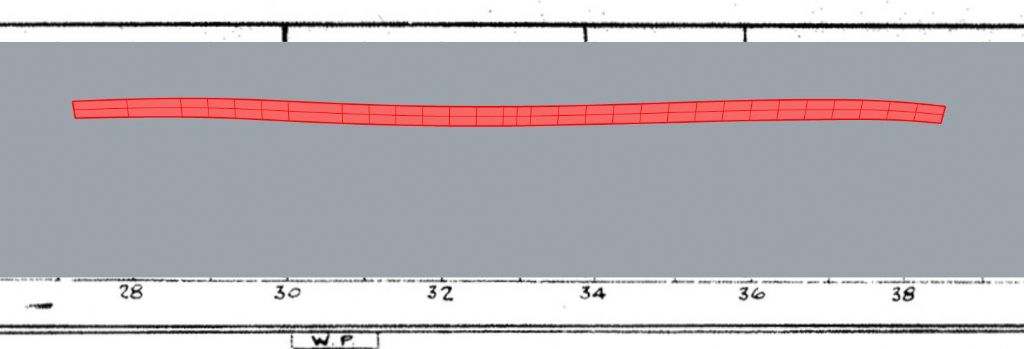

Looking at your original construction description and photos, the splits in the lower hull appear difficult to explain. It is conventional plank on frame using western red cedar and should have given no problems at all.

However, reading further reminded me that after glassing the inside and applying tissue to the inside you detached the lower hull from the sheeted topsides and removed much of the supporting framing, (inc. all cross beams?), relying on the GRP/Cedar/Tissue 'sandwich' to maintain the shape. (Page 18). This in turn reminded me of problems I have experienced with several kit review models I have made which featured GRP hulls. In almost all cases the hull had distorted after being removed from the mould and boxed up for sale. In most instances this manifested as the hull sides curling in to a considerable extent and in some cases the bottom would bow up amidships as well.

It is a common problem and caused by the hull continuing to cure after mould removal. The solution is to force the hull back into shape either by judicious internal framing or forcing the deck into place and then applying heat from a hair dryer. The hull will then cool and take on the desired shape. A bow in the keel can usually be cured by forcing it flat with a heavy weight and again applying gentle heat. Some internal framing and the deck still needs to be in place to maintain the desired shape.

These are usually polyester resin hulls but it is quite possible that epoxy exhibits similar plasticity. If so then your glassing, by a combination of curing, thermal movement (with ambient temperature changes) and removal of some of the original support has permitted a degree of movement which has overstressed the ‘sandwich’ and resulted in the splits. Wahine is an unusually large model and this sort of problem might not be apparent in the smaller models which most people build and sheath in GRP where stresses would be much less.

I am no expert but I suspect that this may be at the root of the problem. Like Ray, I’m not a great enthusiast for glass sheathing as I don’t like mixing materials with different thermal coefficients. I have done it on the LitePly hull Fairey powerboat kits but they are only a couple of feet long. My 48 inch Fishery cruiser has a balsa planked lower hull and ply upper hull but the ‘plating’ is in fact gumstrip paper saturated in shellac. All natural material and no problems!

With Wahine it is difficult to be definitive but it does seem that the root of the problem is the GRP/cedar sandwich and its supporting structure. I can’t believe the application of the cedar planks to the original frames should have been an issue. Your replacement lower hull may well be better off with conventional sealing and paint finishes which match the wood.

Colin

Edited By Colin Bishop on 27/05/2021 18:47:25

Ray Wood 3.

Ray Wood 3.

![dscn8512[1].jpg dscn8512[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/894651.jpg)

![dscn8513[1].jpg dscn8513[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/894652.jpg)

![dscn8514[1].jpg dscn8514[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/894653.jpg)

![dscn8515[1].jpg dscn8515[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/894654.jpg)