Hello again, back home in the cold!

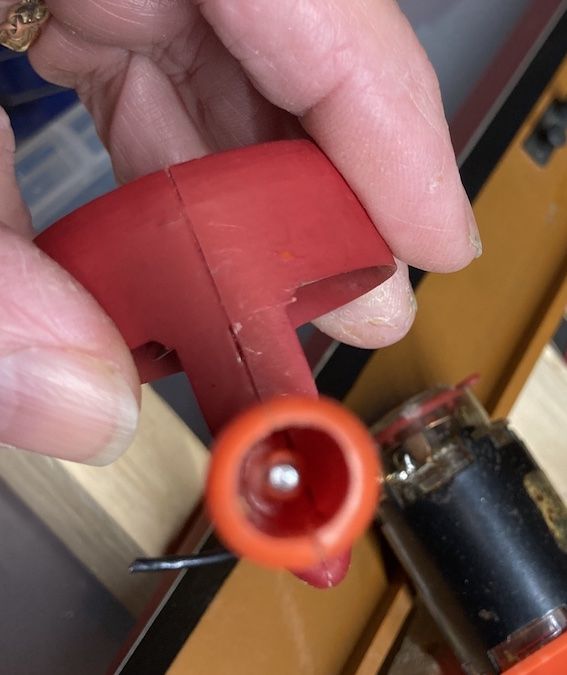

Right, update for those interested, and again thanks for the searches made and the material produced. I prised apart the drive assembly for one unit very carefully and luckily age was on my side as the glue used broke apart easily. The two halves are slightly different, one having ledges to hold the shafts the other capping plates to keep the shafts in place. No grease inside but this unit had a feather jammed into the inner part of the propeller drum.

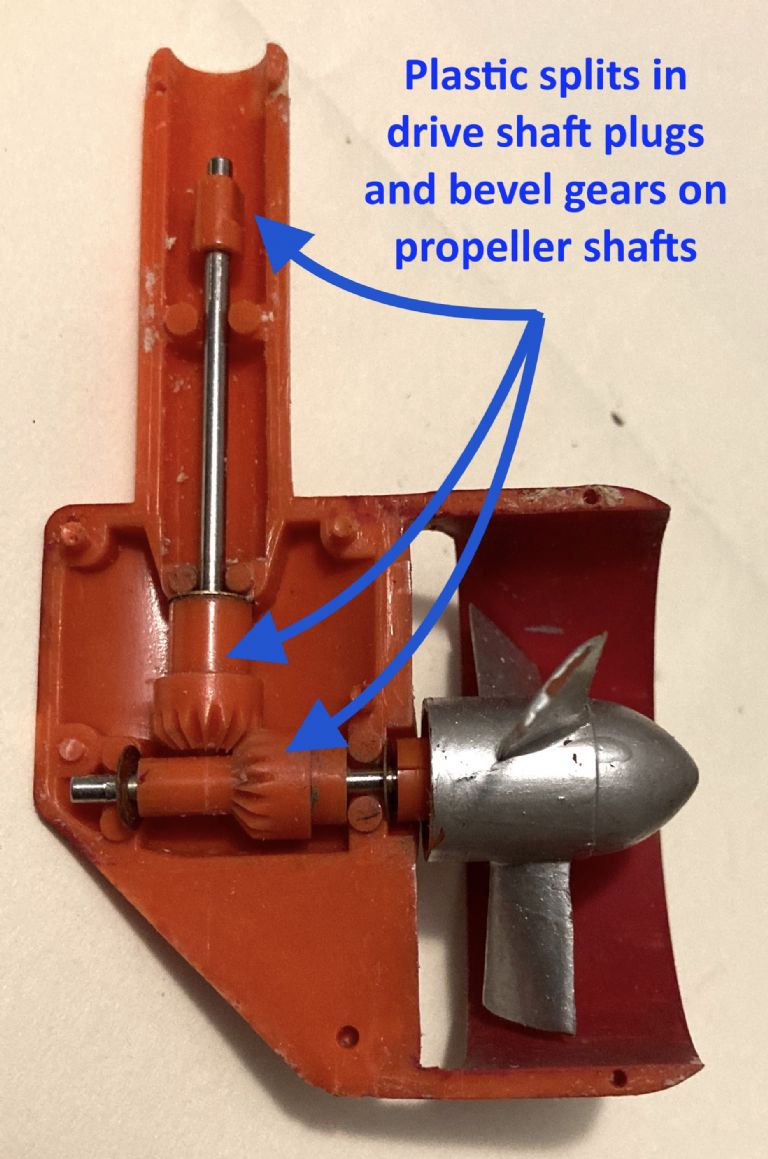

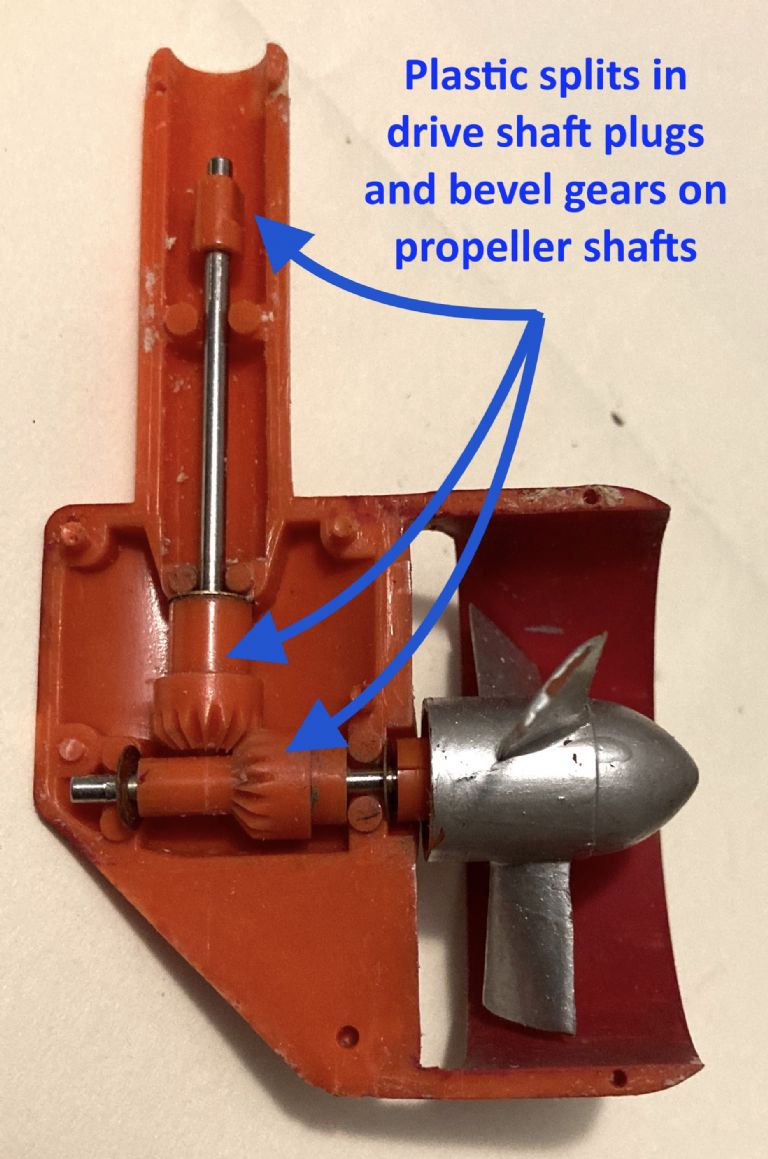

Hers's the assembly as opened.

Hers's the assembly as opened.

Examination revealed more damaged parts, splits in the plastic parts which were pressed onto the shafts. They include the drive locating lug, bevel gear on the propeller shaft and that on the drive shaft though the later two were quite solid and not slipping when pressure applied by hand.

Glue is not going to be a solution, neither will pinning all these bits. Looking at the second unit similar splits were also present in the coupling lug and the bevel on the propeller shaft. So how to move forward?

Now the luck comes in…. A trip to the model shop (yes we still have one local) for some small brass screws when I spotted the adjacent shop had 3D printed items in the window. Popped in and yes, they dealt in some items 3D printed but from re-cycled materials, like lemon and orange peel, and used coffee granules. Interesting but not helpful until the owner mentioned the new shop 5 doors down from him. They do 3D printing he said.

Well hurried there and YES eureka!!!!! Not only was the shop set up with 3D printers operating and spool upon spool of material all about, these chaps were fully into back engineering and making bespoke items for anybody.

Went back with the drive units. No problem, they could easily replicate the drive gears, in a much stronger UV activated polymer, in fact could do the whole assembly at the same scale or whatever. Initial cost to create the files for just the gears and plug estimated at £30 with production cost of £5 per set (plug, and two bevels). He's working on them right now, when I left yesterday he was hoping to complete for today.

Anyone want a Bongo unit? Just kidding…. or are we?

Aye, Kimmo