Hi Ray,

Batteries at the stern was my thought as well. It would make it sit naturally in the water.

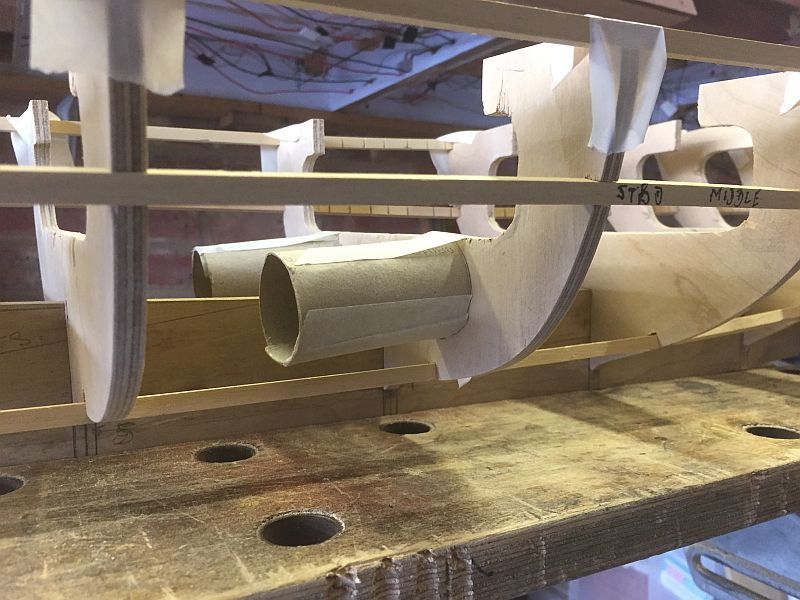

With this dry run I can get some idea of how much to cut out and from the best places.

I`m going to use the 1/16" marine ply that I have here and double diagonal plank for as much as I can. A lot of cutting out making planks ahead!!

My only problem at the moment is that the hull starts as a double chine at the bow and changes to a round bilge from mid boat to the stern, something I`ve not tackled before.To me that means I may have to plank differently at the bow end. Possibly plank at a different angle, we`ll see.

Ray , a few blogs back you asked what the boat would look like. During trying to find pictures , I Googled, " The Pilot boat Vanquisher" and found very nice,17minute video of it on it`s last trip from The Camber at Portsmouth to Port Solent on it`s way to Africa. The superstructure in the film is white but I shall paint it orange, as I used to see it. What also was useful in the film was the amount of detail to be seen. A bit of a bonus. This is going to be quite a project for me and using two motors will be a first. I`m afraid I shall be asking a lot more questions soon.

Regards,

Jim.

. So far, no leak problems despite the inevitable beginner's crashes !

. So far, no leak problems despite the inevitable beginner's crashes !