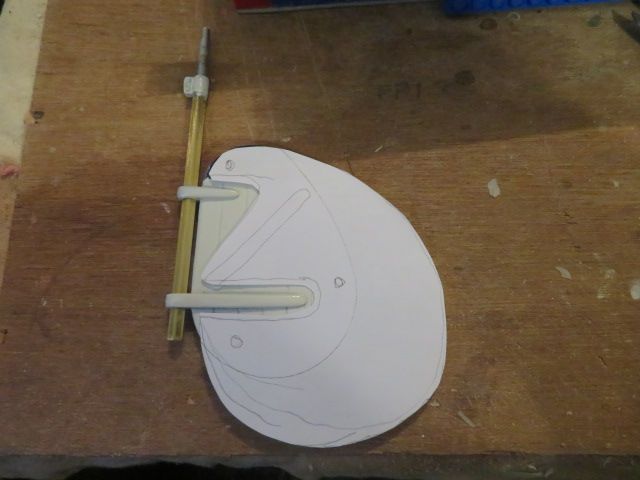

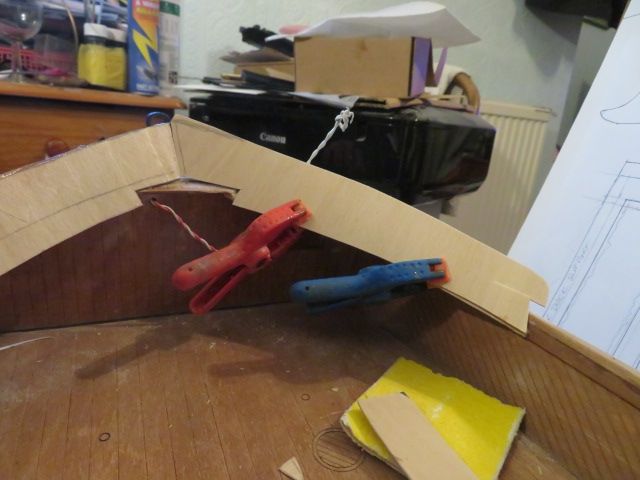

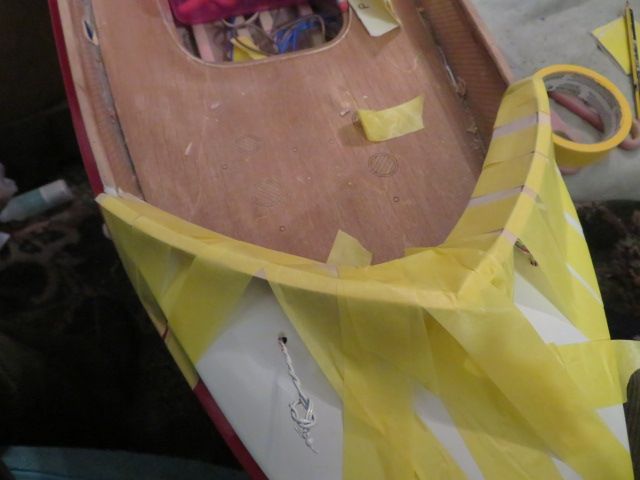

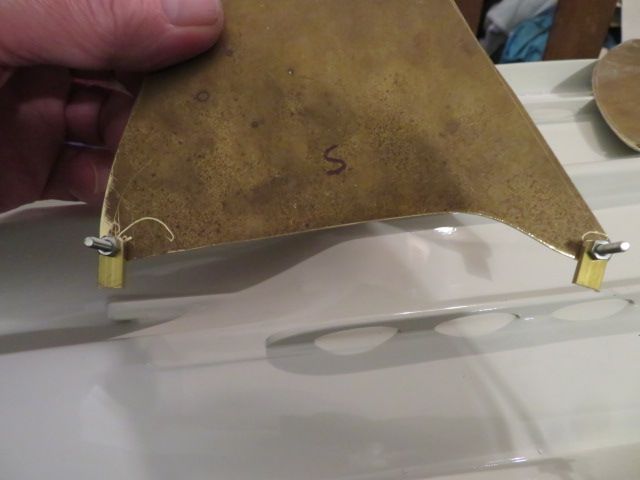

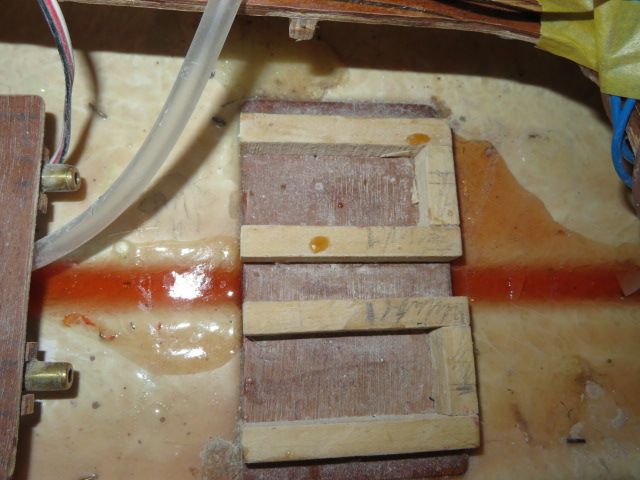

The parts for the rope bins have been cut to size and will be glue together this evening.

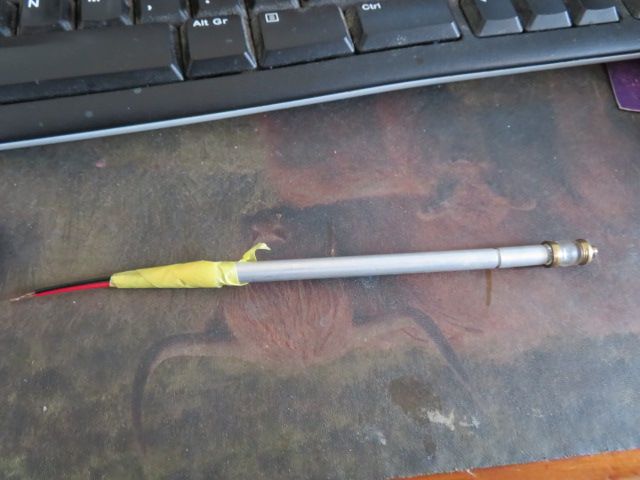

I bought some new band saw blades at 10 TPI to cut the thin box wood timber I had [ I'm saving the lovely timber supplied in the kit for my next scratch build lifeboat, come 2023] to size.

They always do and always have come as a 3 "spring" coil and to simply uncoil without slicing your fingers and wrists on the sharp bladed, you cut the zip ties and then drop them to the floor where they happily will un coil themselves.

Then just a matter of mounting them on the two wheels of the band saw, tension it all up and cut away.

Which I did friday, as I have done hundreds if not a thousand times for the past 48 years of my career………… AND set to work cutting the softest thinnest piece of box wood.

Within the first second of offering the 10mm thick timber to the blade, it was "running off"……..just wasn't following a perfect line and veering inwards, and for a new blade this just shouldn't have been happening, but as I was fealing rough I chucked in the towel, and left it all, thinking that the "new" blade from a packet was a duff blade.

I came in and ordered some new 4/6 TPI blades and left until today when my new blades arived.

Went out to fit a new blade but before I did, just looked at the "duff" blade, and suddenly realised why the blade wasn't cutting! When it sprung out from its coil, it also sprung inside out, [not looking], I mounted it so that in fact the blade on the down stroke at the table was cutting the timber with the back of each saw blade and not the front sharp edge……

That will teach me to take my reading glasses out with me so that I can actually see what i'm doing………….but in all honesty, I HAVE NEVER had a blade do that when uncoiling in all my years.

So the cutting of the timber then went to plan, plainly and easily.all I can say is………….i've neve cut my medium rare steak with the back edge of a butter nife, and that is what it was like.

And the rope bins went together quite easily using aliphatic quick grab waterproof wood resin glue. There is one under the camera but had a very slight twist to it so is gluing square and "flat" with the weight of the camera helping.