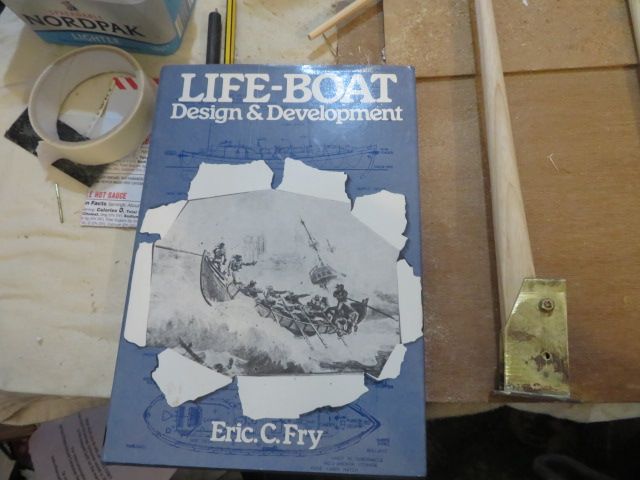

Masts for my Liverpool next, and so I visited one of my favourite books, and for some reason have 2 copies, lol

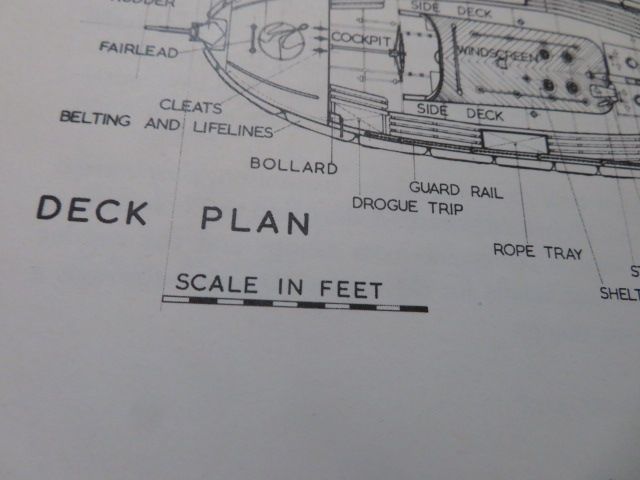

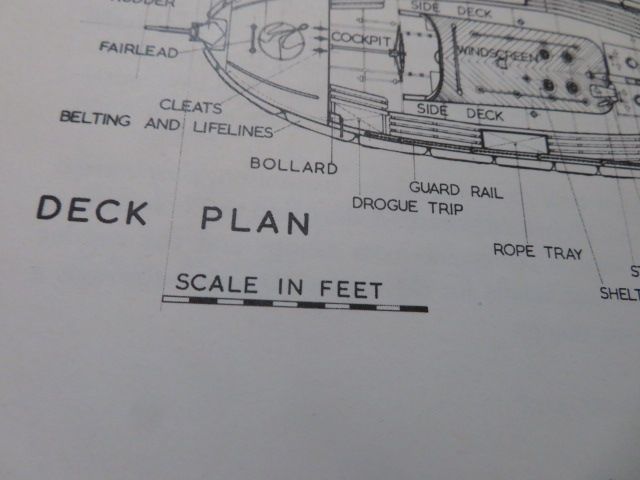

Looked up the Liverpool class and there it was as remembered….a scale for the profile plans, including lengths of masts ,spar and boom……….

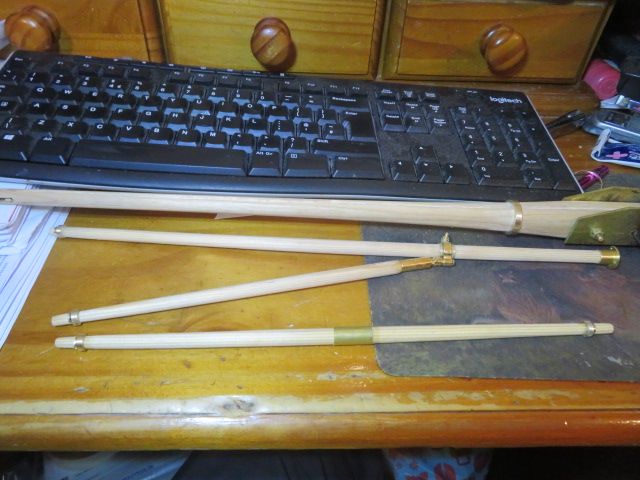

So cut these to length from 8mm ash doweling that i had in stock.

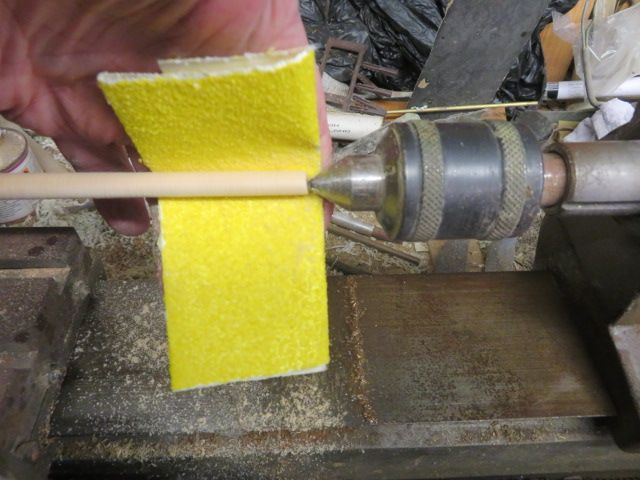

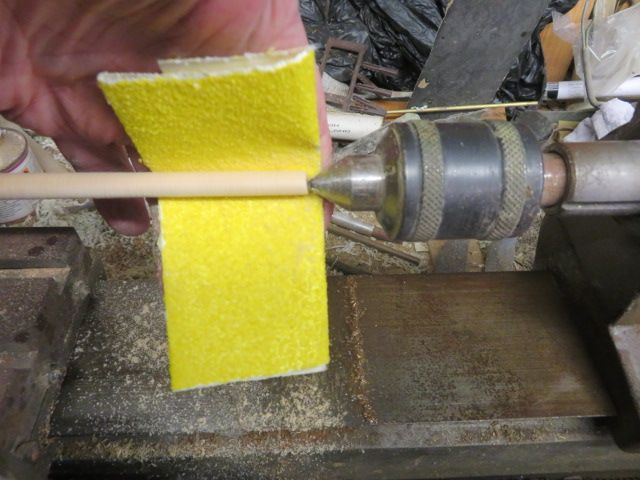

Both ends of the mainmast spar, the mizzen mast and boom at one end needed to be tapered, and so marked centre of each end to be tapered and then drilled first with a 1mm and then a 2mm dia x 4mm deep hole, to take the "live centre" in the tail stock of the lathe.

Mounting each length of dowel into the head stock and pinning up with the live centre in the tail stock, I turned the lathe on in reverse, so that the dowel was running away from me as I began sanding the taper with 40 grade, then 60 grade and then taking out of the clutches of the lathe to sand by hand.

The final sanding, to get rid of the circular scratching left by the abrasive paper cutting across the grain, was done length ways up and down the length of the mast, with 120 grade abrasive paper, leaving a nice smooth finish to the timber.

Tomorrow I shall be using the lathe again to turn, from brass the step for the mizzen mast, and other mast rings to fit each part of both masts, spar and boom……….

Might take a little longer than the 35 minutes it took me to taper the other pieces,

AND AT ALL TIMES……..safety first with a powerful lathe……roll up your sleeves and keep loose fitting clothes away from the head stock whilst in motion.