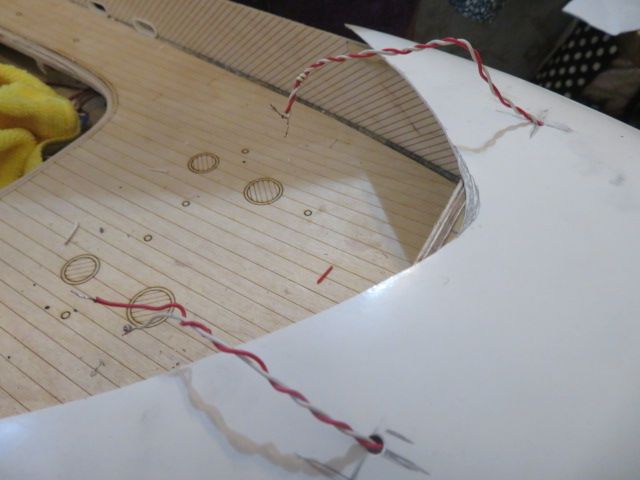

I have the hull of the Liverpool sat on a warm radiator at the moment, as I have added some milliput white into the cut outs in the belting to get a nice clean surface to the inner recesses once filed and sanded…

But more importantly I have had to put a strengthening fillet of milliput all around the main bilge keels. the reson being………I'm a clumsy sod and over the period that they have been fitted, I have kept knocking them as I have worked on the top side of the boat, and on has become loose at the foreward end…………..the fillets will be sanded to blend in once set, but for now it has hampered progress for a few hours.

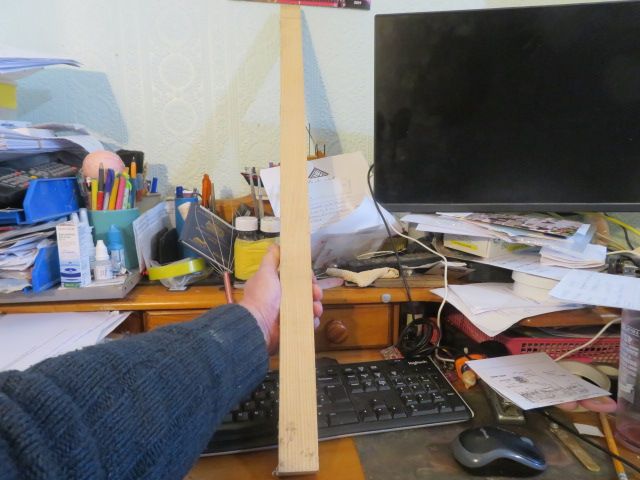

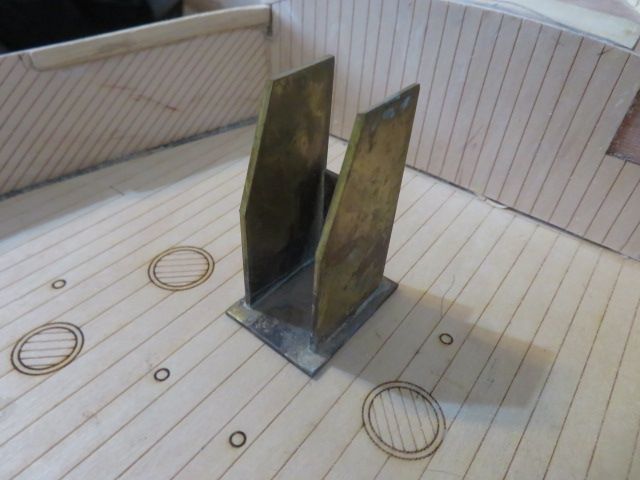

And so, I have turned my attention to something I can do off the boat……..the tabernacle for the main mast.

I wont be using the one from the kit, as I think it would take too much hammering whilst on the Windermere sail should the winds be strong.

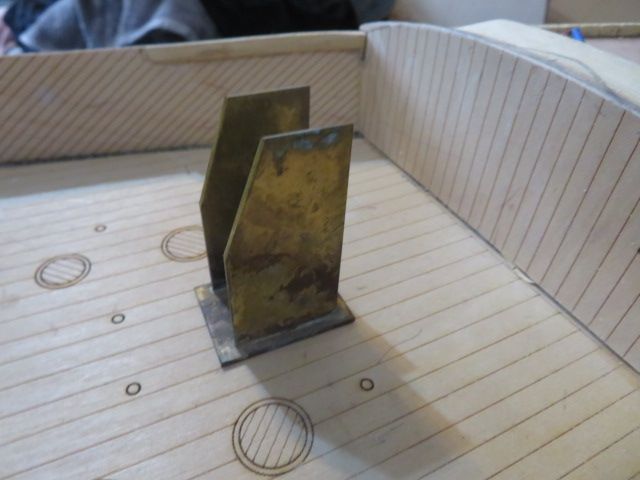

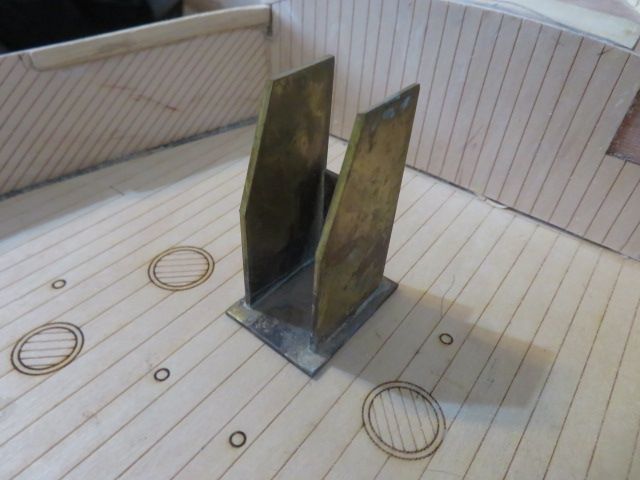

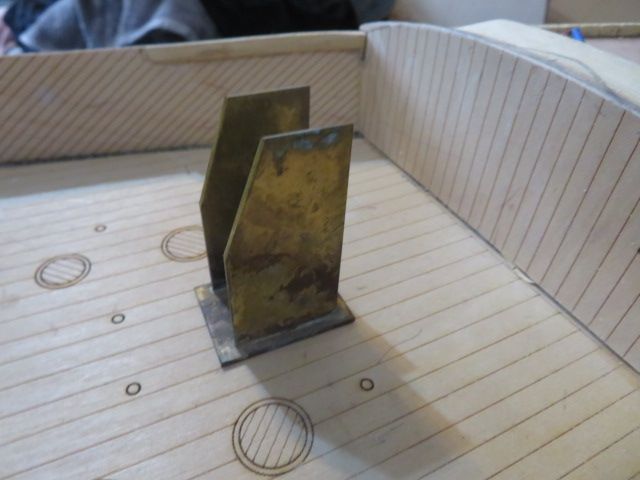

And so I have reverted to one of 4 tabernacles that a friend made for me out of 1.2mm brass, silver soldered, some time ago when I was building my two sailing lifeboats, and whilst he was working for Fleetwood Lighting Co. Ltd……….and what a lovely job he made of them to………probably need a hurricane to break this one.

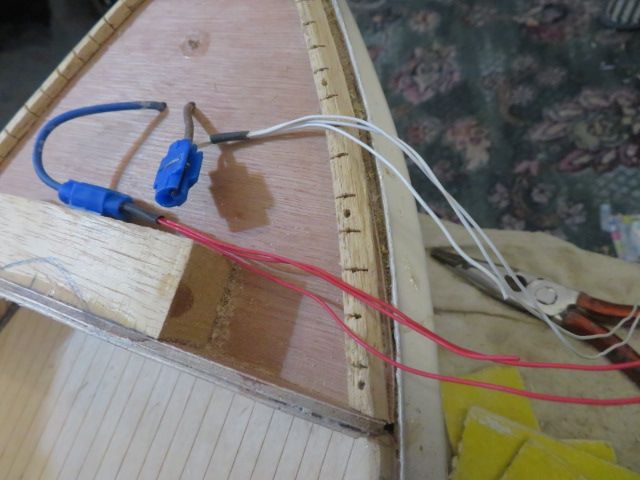

The base will be drilled in 3 places and screwed to the deck which was strengthened underneath with 6mm ply in 3 seperate layers. the upright sides will also be drilled to take the mast pivot and the locking bar as well, once I have made the mast, which itself will be a custom made mast from Ash rather than the dowel supplied in the kit………..ABSOLUTELY NOTHING wrong with any of the timber supplied in the kit, in fact it is excellent quality. But i'm just taking extra precautios of every kind to avoid anything going wrong mid lake knowing what the weather can be like on a very open large lake. If such weather can break masts of actual yachts on Windermere, It can certainly do so on a model.

I failed [or my boat did under the command of my friend Dave Forrester] on the Loch Ness sail in 2011 to reach the end because I hadn't made provisions for what we were facing, and one failure in an endurance sail is enough…….I have learned my lesson, and treating this one more seriosly.

Hence the modifications to the boat I have chosen.

?

?