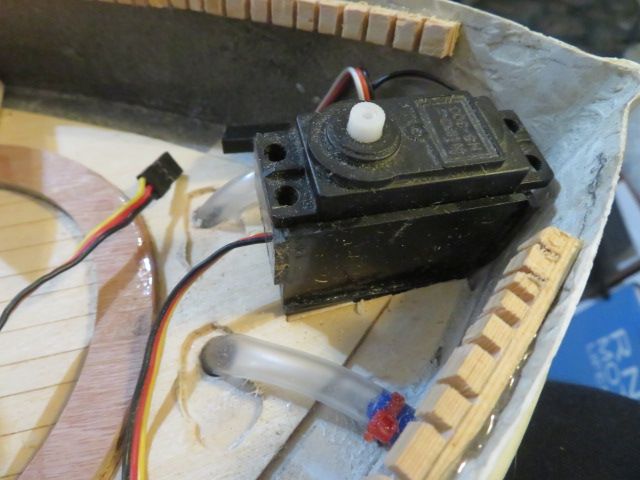

And so!, the last deviation in the kit build of the Liverpool class lifeboat, from the kit as designed and produced, and of course the expectations that this wee boat at 37" long, compared with the monsters that Steve Bennett, Martin Kinghoward and Mike Pendlebury have built for the run, is going to get swamped, have had to come up with a way of freeing the water from the deck.

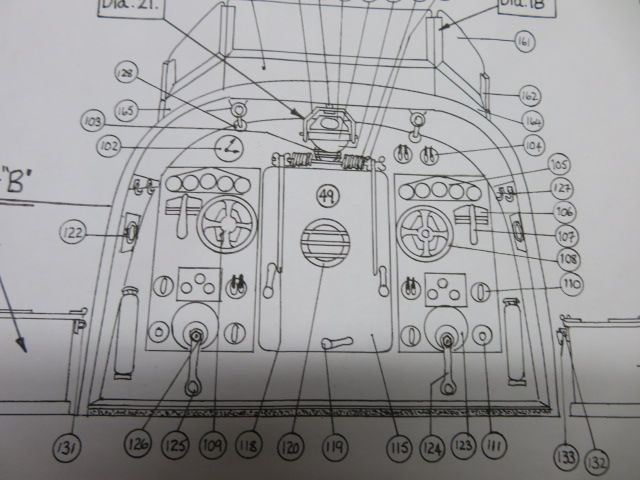

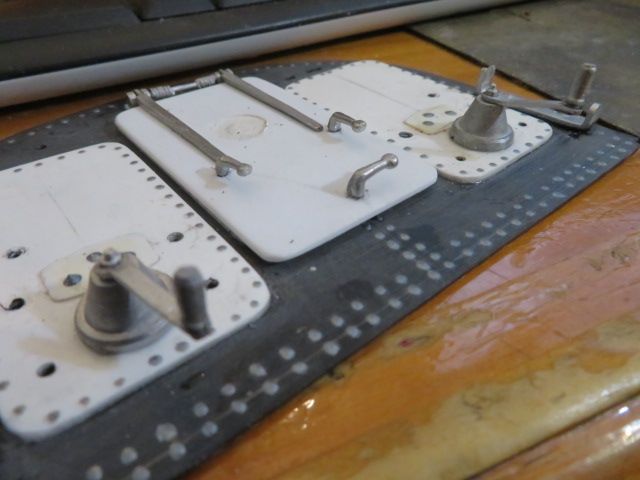

The real boats had a series of none return deck valves, allowing the water to drain out through tubes to the hinged plates on the side of the boats hull, but the feasability of me getting these to work was beyond my patience or cababilities.

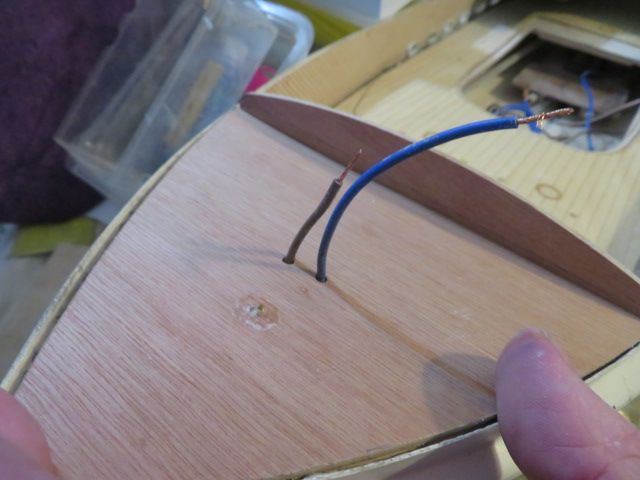

So, I resorted to cutting some oval holes into the scuppers, just below the belting and at deck level on the inside. of the bulwarks.

The inners were made from the plastic "weight" of an old roller blind, and I had just enough to cut on the band saw to a width suitable for my needs.

As they are tucked immediately under the hull raised belting

[painted red], these will be sprayed blue along with the hull, and from a meter away, I dont think they will be too visible, camoflaged by the hull and belting……….and to any rivet counters……….raspberries to them and the winnie victory sign.

Of course once the inner printed ply bulwark capping strips have been fitted, before spraying, the inner holes will be drilled and sanded in the ply, and then the holes filled with milliput and moulded and sanded flush before the hull is sprayed blue.

And finally I needed some liquid refreshment after all the dust of cutting and shaping the holes had been done.

Edited By neil howard-pritchard on 21/01/2022 16:25:58