This morning wasn't a great start to a Friday and weekend, as I had a "date" with destiny for a dear friend of mine, and from the turnout at the Crematorium a good friend of many. Even the coxs'n and crewman fron our lifeboat were there as Allan spent many an hour collecting for the station and photographing the crew and boat for publication for the station.

A man called Allan Macfarlane, whom I met a good 15 years ago, when he was serving my daughters and I our favourite sweet………ice cream. at the ferry cafe close to the RNLI Station in Fleetwood. we got chatting and I found he came from one of our favourite haunts as a family, Milport, on Cumbrae, on the Clyde river.

Hit it off and became freinds immediately. I have highlighted his name, as he was a brilliant photographer, and if anyone is interested in photography, his name lives on through his photos on facebook………have a look. **LINK**

So after the service, the best way for me to celebrate his life was to go and have an ice cream on the prom at fleetwood, and wish him good travels where ever he is, in this great universe.

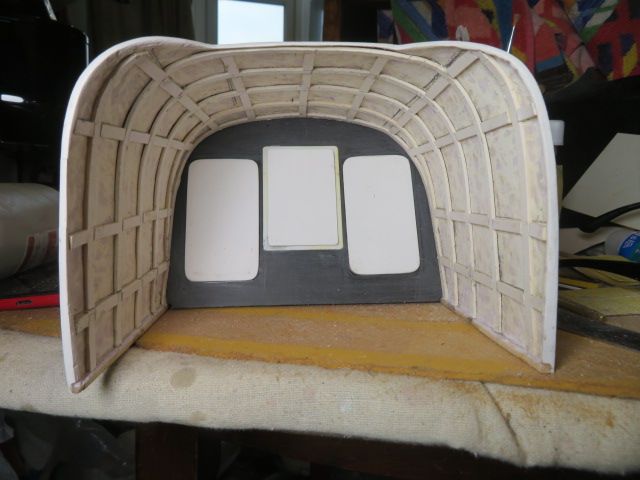

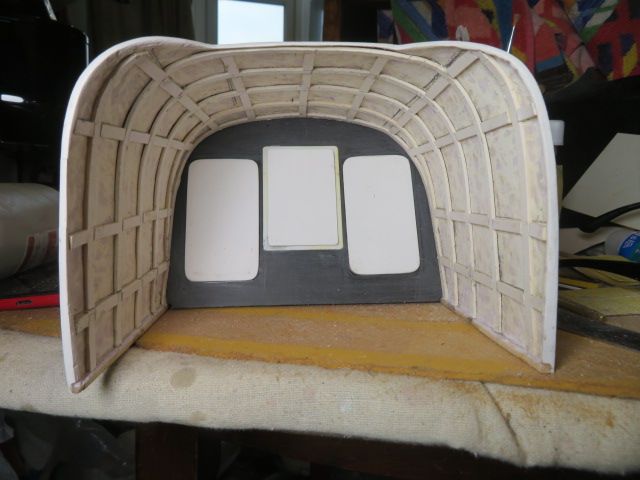

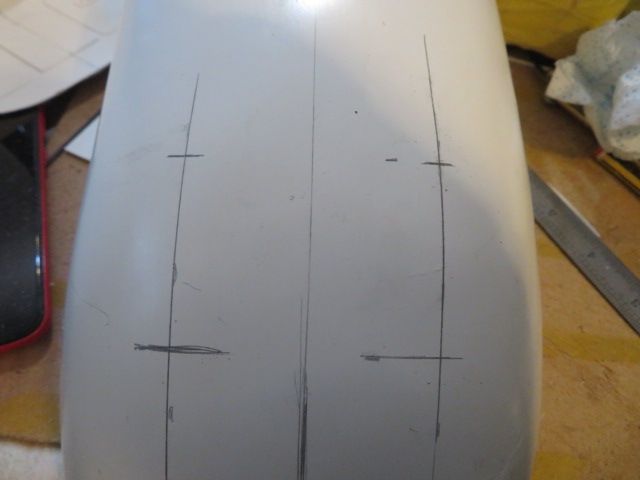

After an hour or so I came home, changed out of my suit, sat down and decided to make a new inner bulkhead for the cockpit, or should I now start calling it the proper name that old crew men on Liverpools did………the "whaleback".

Because of my tinkering with it to get it to fit tightly into the recess I have made on deck, it has widenned by around 5 mm, and as such the grp formed bulkhead and deck were just slightly too narrow.

As such I made a card template for a new bulkhead, shod it with the panels for the motor dials, switches, gear wheels etc from 0.5, 1 and 1.5 mm plasticard, and mounted them on to the 2mm thick bulkhead. and then sat back waiting them to set.