Hi John

Very interested in any info you have, i want to fit working lights so any info you have on colours will be very welcome.

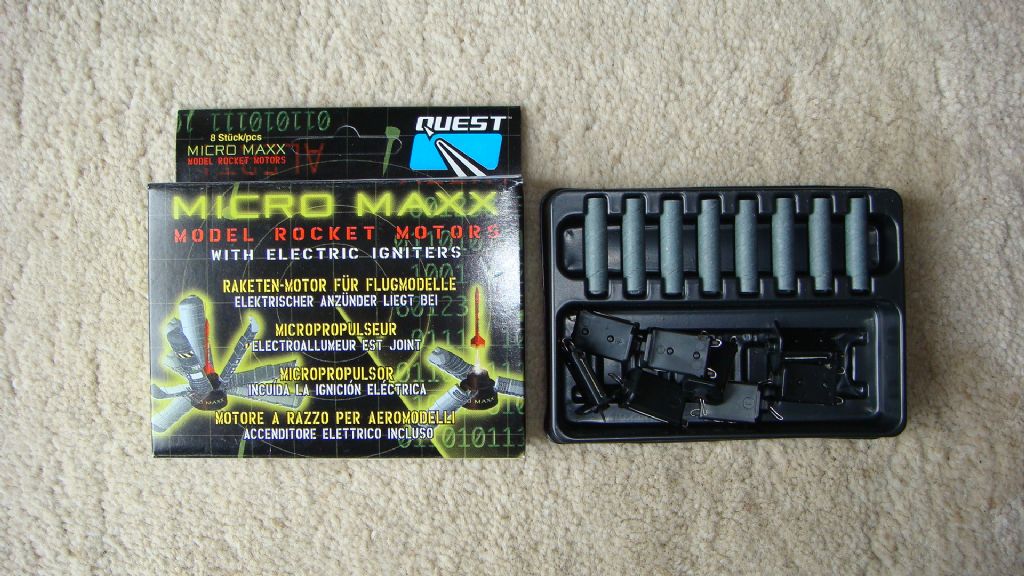

Rockets sound interesting again would like to see methods, with my luck after months of building a rocket would ignite but fail to fire, resulting to a boat resembling a viking funeral.

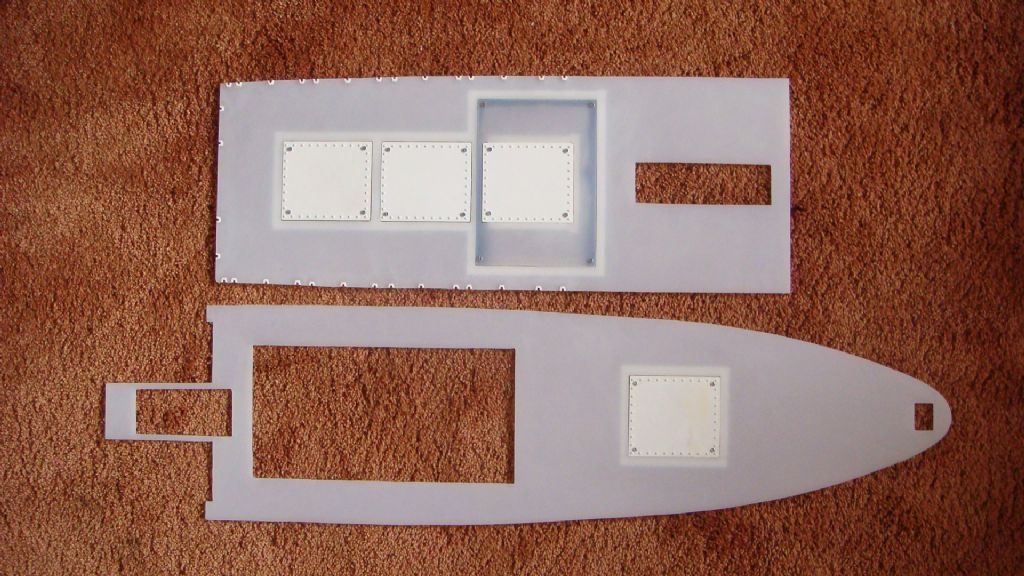

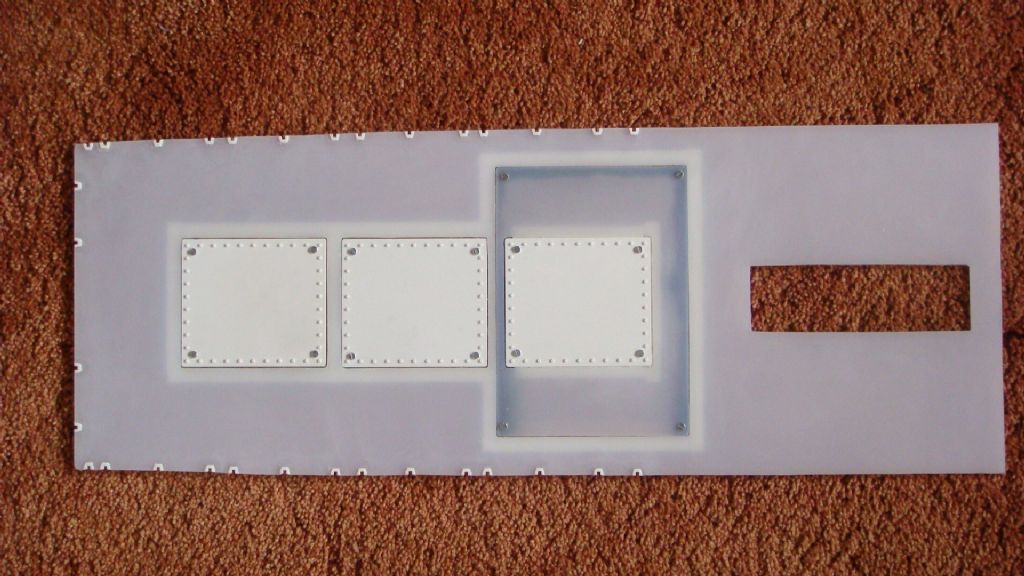

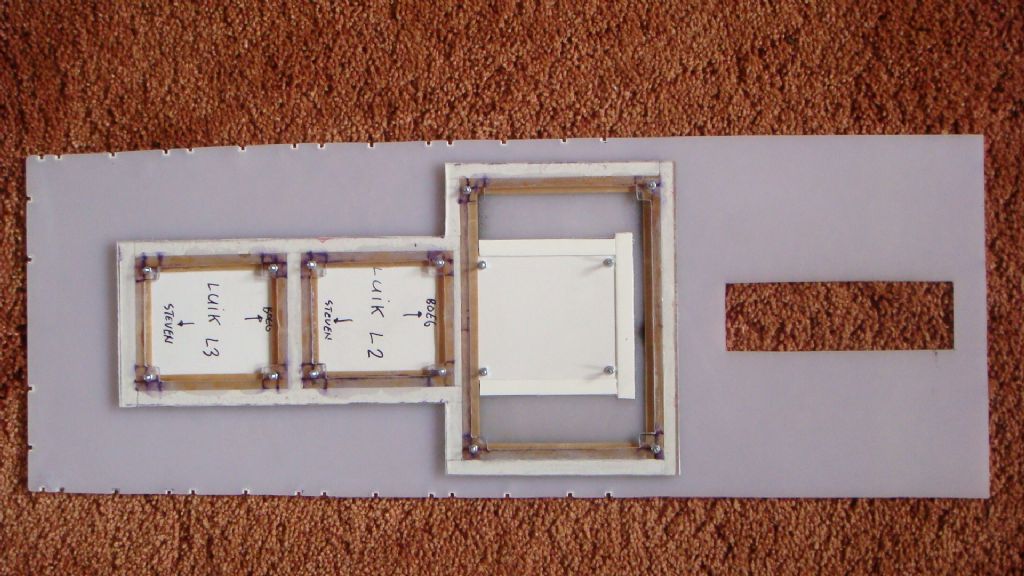

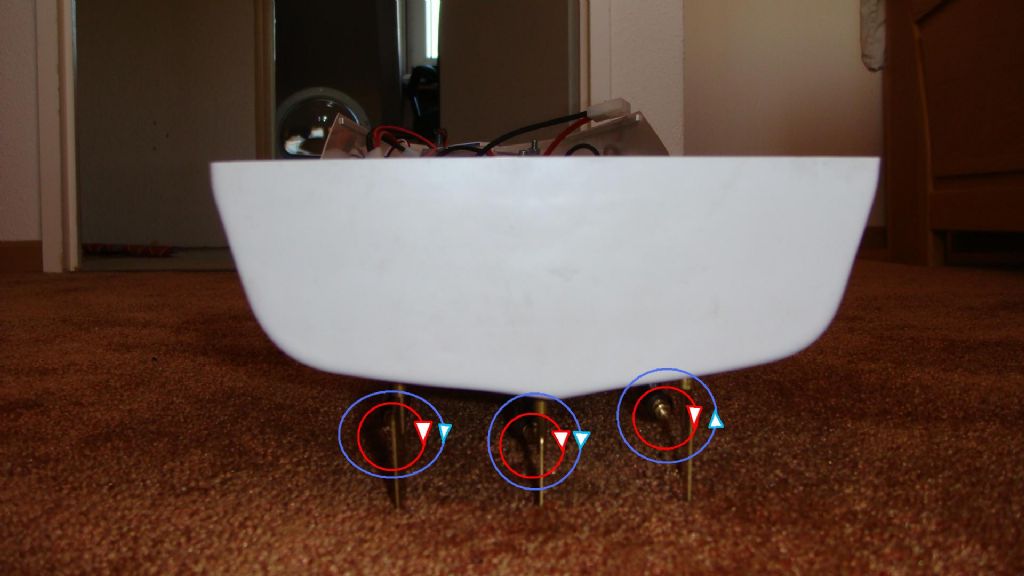

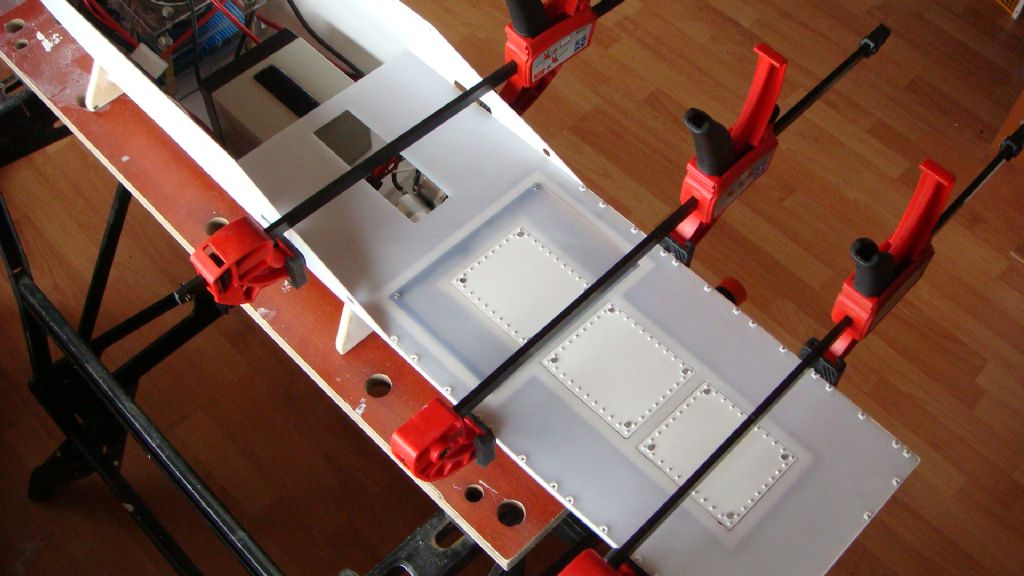

I will have to learn how to post pictures, i do build slowly even when i have time to build, i will spend ages making sure the 3 shafts are parallel and inclined at the same angle.

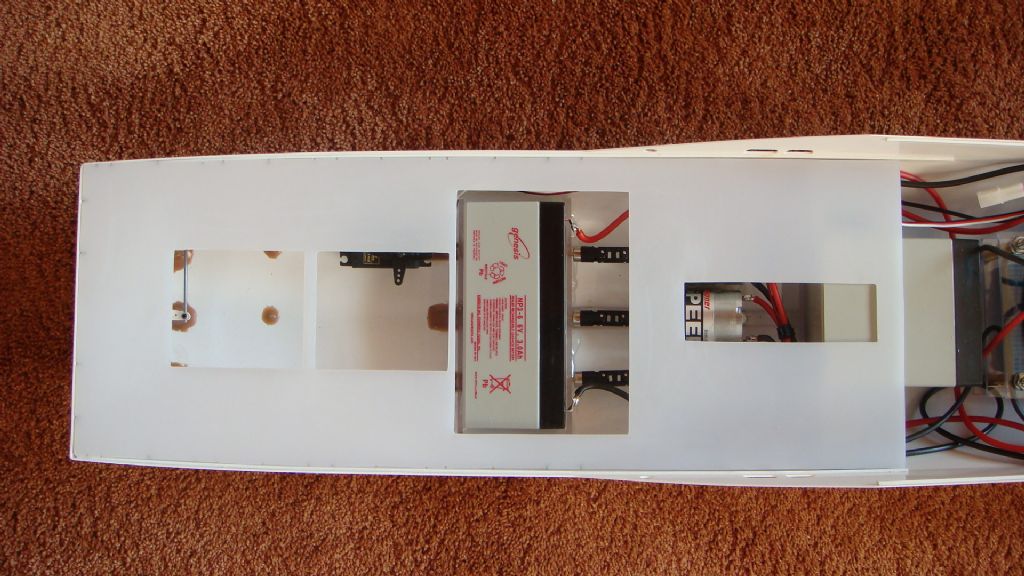

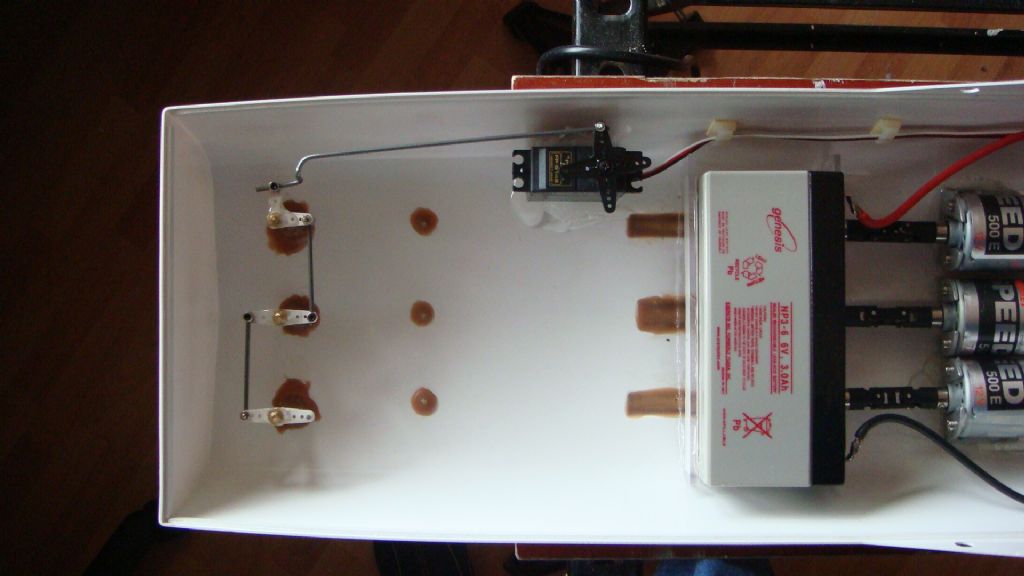

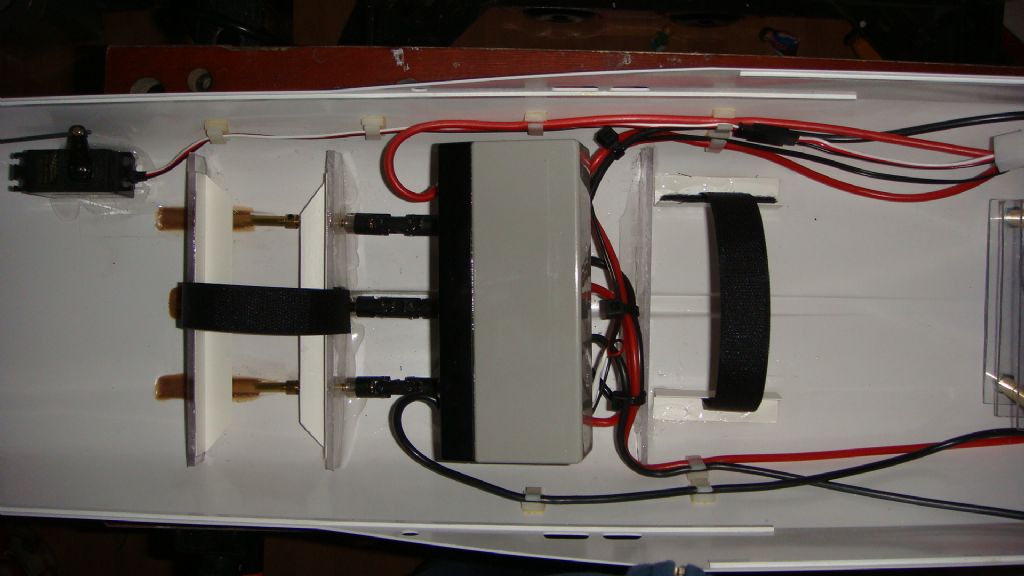

when i fit the motors i am going to try to put a big one in the middle. outers will be on a speed controller, centre on a servo/microswith run from a y-lead. This will be set to cut in on full forward, this will limit speed in reverse and reduce risk of swamping.

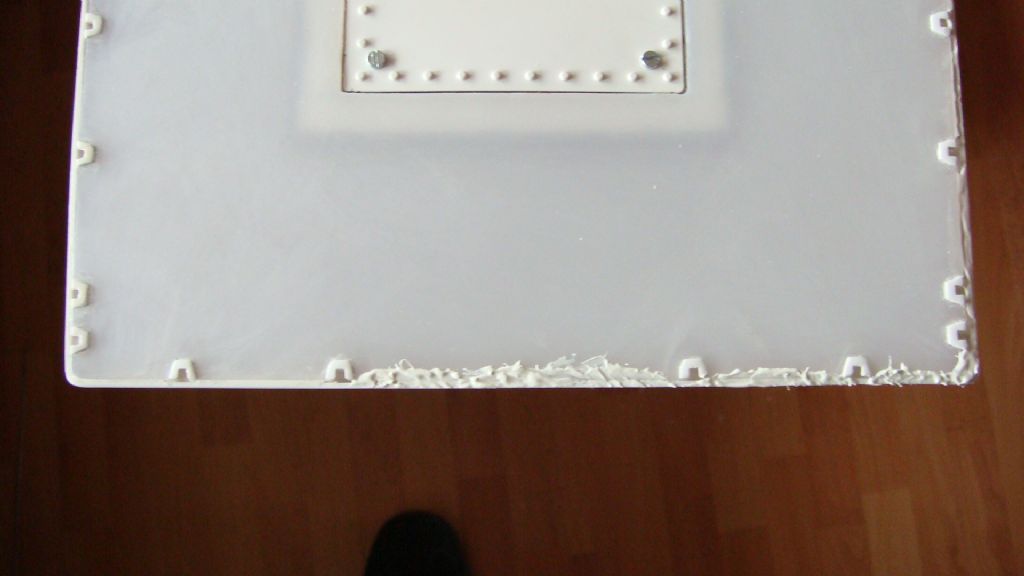

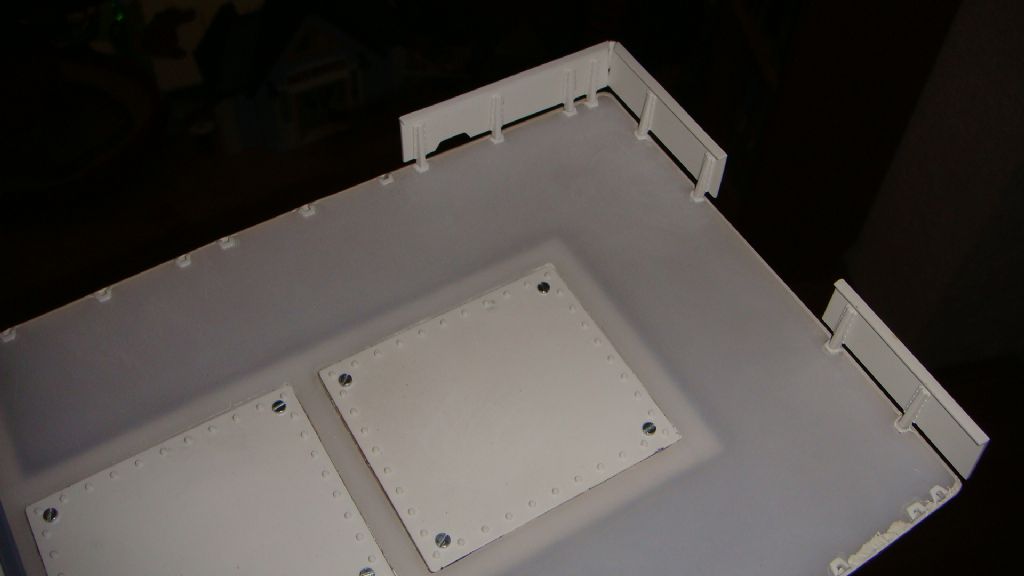

Whun i fit motors i have alredy fully secured the shafts, i then substitute the universal joint part of the coupling (the red bit) with an equal length of 11/32 outside diameter brass tube(i find the internal bore of this a snug fit onto the coulling ends. Te motors are thus secured with effectively a solid link to the shaft (much better than aligning by eye), when the motors are secured in it is then just a matter of removing the shaft inner inserting the universal joint and then refitting the inner shaft ( but i do not grease it until after the hull has been sprayed.