Hi Ray,

The short answer is a quote from the waiter 'Manuel' in Faulty Towers…."I know nauauthing".

The explanation is probably that the excessive pre-preparation of parts is due to NO experience at scratch building a boat. I have to make one part at a time in a sort-of logical sequence because I have little idea how the subsequent part/s are to be made in the first place!

The pre-painting is probably because I don't know which paint is going to give the required result. I had a lot of trouble earlier with the hull finish quality. The inexpensive full size boat paint I used did not flow out well at all so I ended up sanding it all down and airbrushing -which I also knew naught about!.

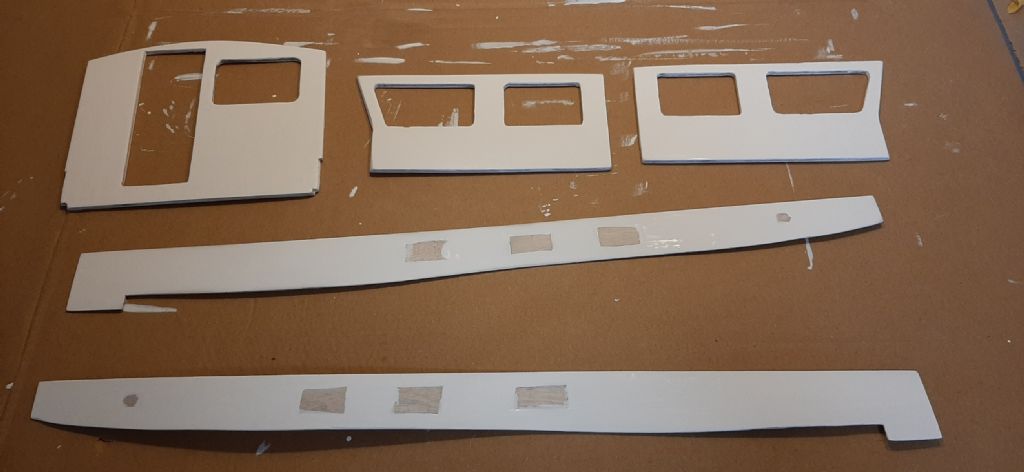

The components of the wheelhouse and cabin sides have now been painted using a well known quality Norwegian paint called 'Bengalack'. This idea came up when I saw that a chap in east Norway use it on his Colin Archer hull. It was smooth and (a bit too) glossy. It gives however the look of a fibreglass finish -even when brushed on- and that's what's needed on the Fisher.

I cannot see how this particular type of boat could be easily treated with sanding sealer, undercoat, sanding down all the surfaces -and corners- with all the 'boxes' ready assembled on deck. The required masking off would be a headache I suspect.

The next Fisher –which I will not be building– could have been a lot easier

I'm sorry, but I'm terrible with giving a short answer. I used to be able to say "Roger" and "Copied" but I'm over that now!

"OUT"

G-ECON

Edited By gecon on 14/11/2020 07:08:22