Hi Steve and welcome to the forum. Just to try to help with some of your questions. Firstly, seeing as there are so many, it would be a lot easier to respond to if they were numbered so I’ll try to dig them out of your text.

So,

1) Adjusting laser cut parts, yes. Especially where there is vac formed plastic involved which notoriously is less than perfect or consistent in its final shape.

2) Are kit instructions vague, yes! Lacking dimensions, yes! Frustrating, yes!, Misleading, yes!

3) Do you need to work four or five steps ahead, yes!

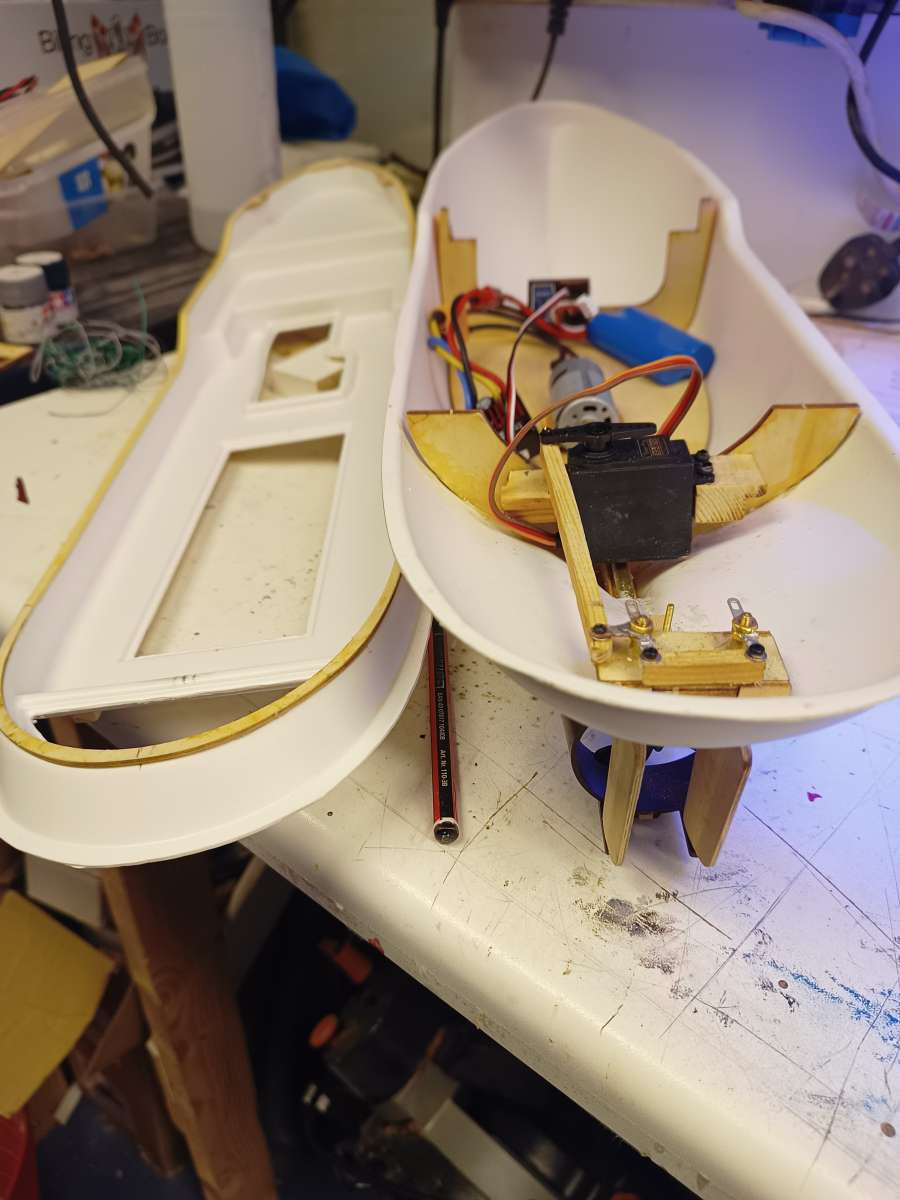

4) The plastic used in these vac formed kits is a polystyrene type. Epoxy I’m afraid does not hold very well. I have just completed a Billing African Queen and used my go-to glue, Araldite, to glue the frames into the hull only to find the hull simply peeled away from the glue. I strongly suspect yours will do the same. The best glue I could find to deal with this was Stabilit Express. It is expensive but it does seem to grab the plastic significantly better. I re-glued my frames in the African Queen with Stabilit and it held much better. It is tricky though as you need to plan and prepare because the glue sets in around five minutes. If you have a big part to glue you need to get the glue on, get the bits together, adjust, and clamp everything up before it starts to cure.

5) Glueing wood to the vac formed plastic can be very successful with good old polystyrene cement. Don’t use the liquid type as it soaks into the wood before it dissolves the surface of the plastic, and don’t use the thin types such as revel Contacta for the same reasons. The best one is the thick type in the tube. This does not soak into the wood quickly, fills gaps nicely and dissolves the surface of the plastic to give a good bond. For your deck and hull joint I would consider this glue.

6) PVA the best stuff for wood to wood.

7) I rarely use cyano in model boats for main structural stuff. It does have its uses in multimedia areas though, such as the boiler and engine in the African Queen.

I think you would find a read of the African Queen review I did interesting. It is in Model Boats Magazine, September and October 2023. Quite often you have to think outside the box and decide as to whether you want to follow the instructions to the letter or, occasionally, do your own thing. The African Queen instructions show the steering servo in the forward locker. If you put it there you would have to remove the mast and forward locker door to even see it, but then you could not get to it. I put mine below the decking.

While kits usually lead you along the path by the hand and you feel you should be able to relax in the knowledge that all the design work is done for you, quite frequently you need to make modifications yourself. Sometimes kits can be more work than building from a plan!

I would take a deep breath and try to pull your hull away from the glued internal frames. If it does, get some Stabilit Express and lay a thick bead over the outside of all the frames where they meet the hull. I also see there seems to be gaps between the hull and the tops of the frames. You need to determine whether the hull needs pulling in to close the gaps or whether the gaps need filling with additional glue. The hull fit to the deck will determine this. When you come to glue the deck and hull together you will need a large quantity of small clamps. I use stainless steel clothes pegs. When the glue goes on you need to clamp that joint quickly and evenly. You can go over the joint afterwards with another bead of glue if you have any gaps but quick clamping should avoid that.

bluetobits.