A lot of concerns here locally as regards Spitfire maintenance after the very sad events on the 25th May. Since then I have also noticed two replica Spitfires have had crashes with similar outcomes on the last few days. We need to remember that these things do not come without their risks.

Nice to see though that the BBMF Lancaster has finally taken to the air again, although no-one is any the wiser as regards when they are going to let the Spitfires and Hurricanes return to active duty.

It does beg the question though, if we ground all the BBMF when they have such an incident with one of the aircraft and they miss out on a large portion of the Summer’s display commitments, are we getting to the point where we should be considering pulling the plug on the BBMF? My take is that we should keep them going, but then we shouldn’t ground the whole lot for the entire Summer because one has had a failure.

I once had an hour in a Tiger Moth, around ten years ago, and flew it over Ladybower Reservoir to follow the practice runs that the Lancasters did in preparation for Operation Chastise. That was pretty basic! I looked up the reg number only a couple of weeks ago to see where the aircraft is nowadays, to find it crashed!

gecon.

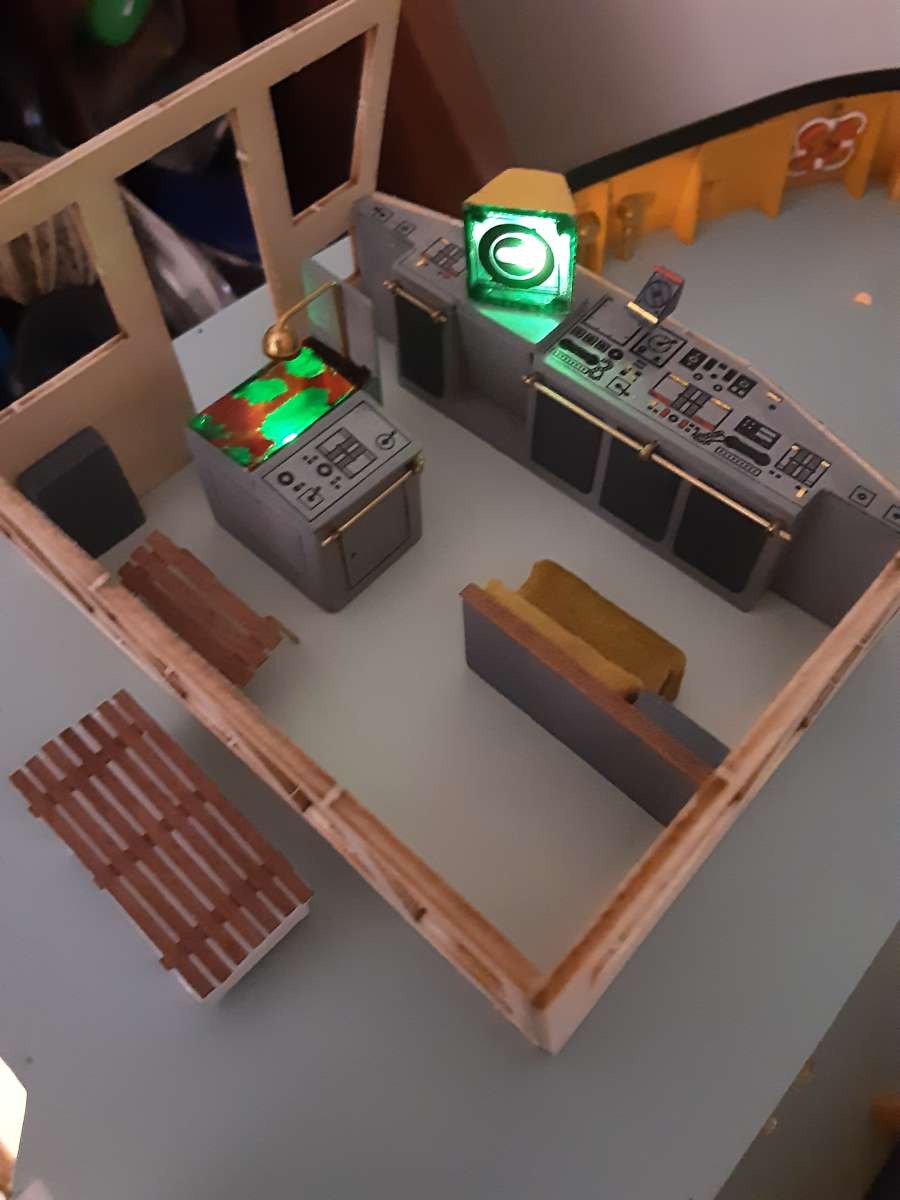

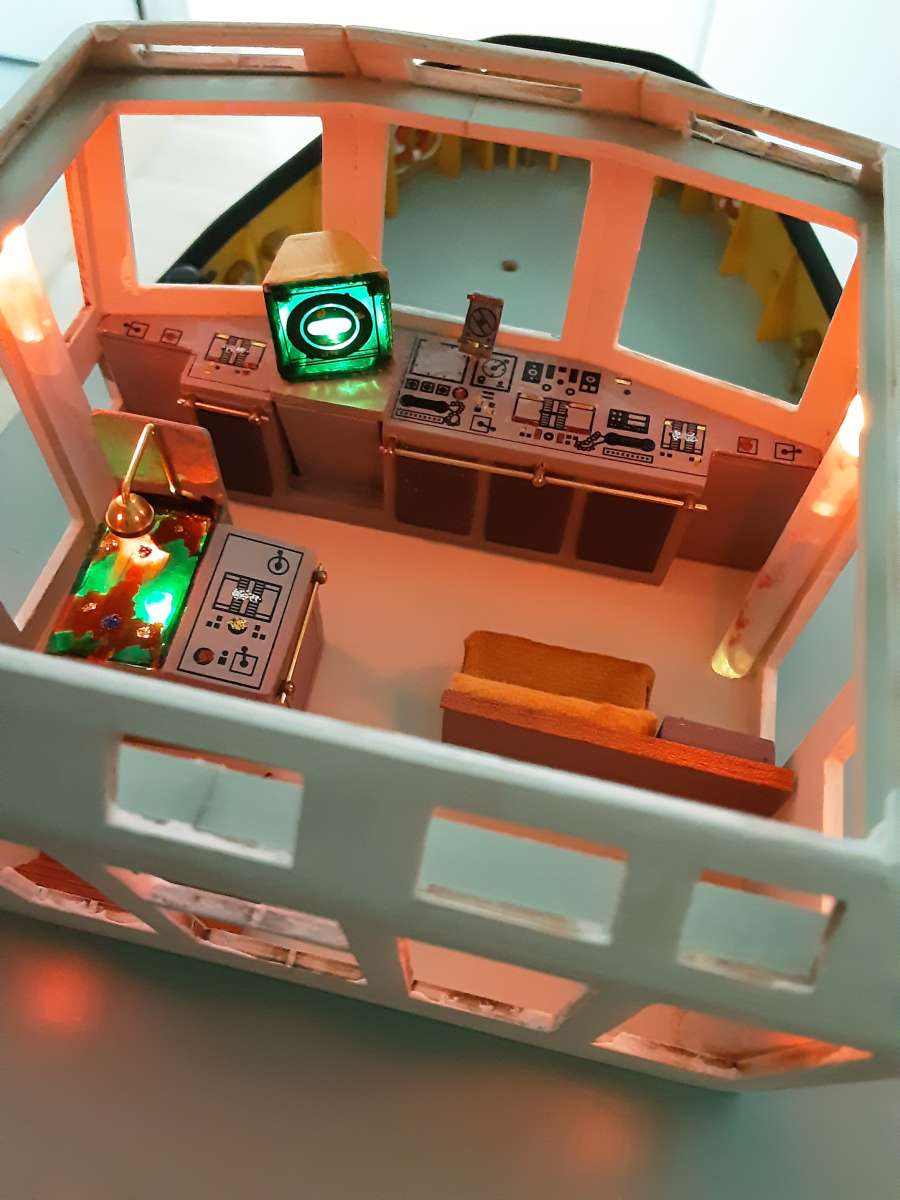

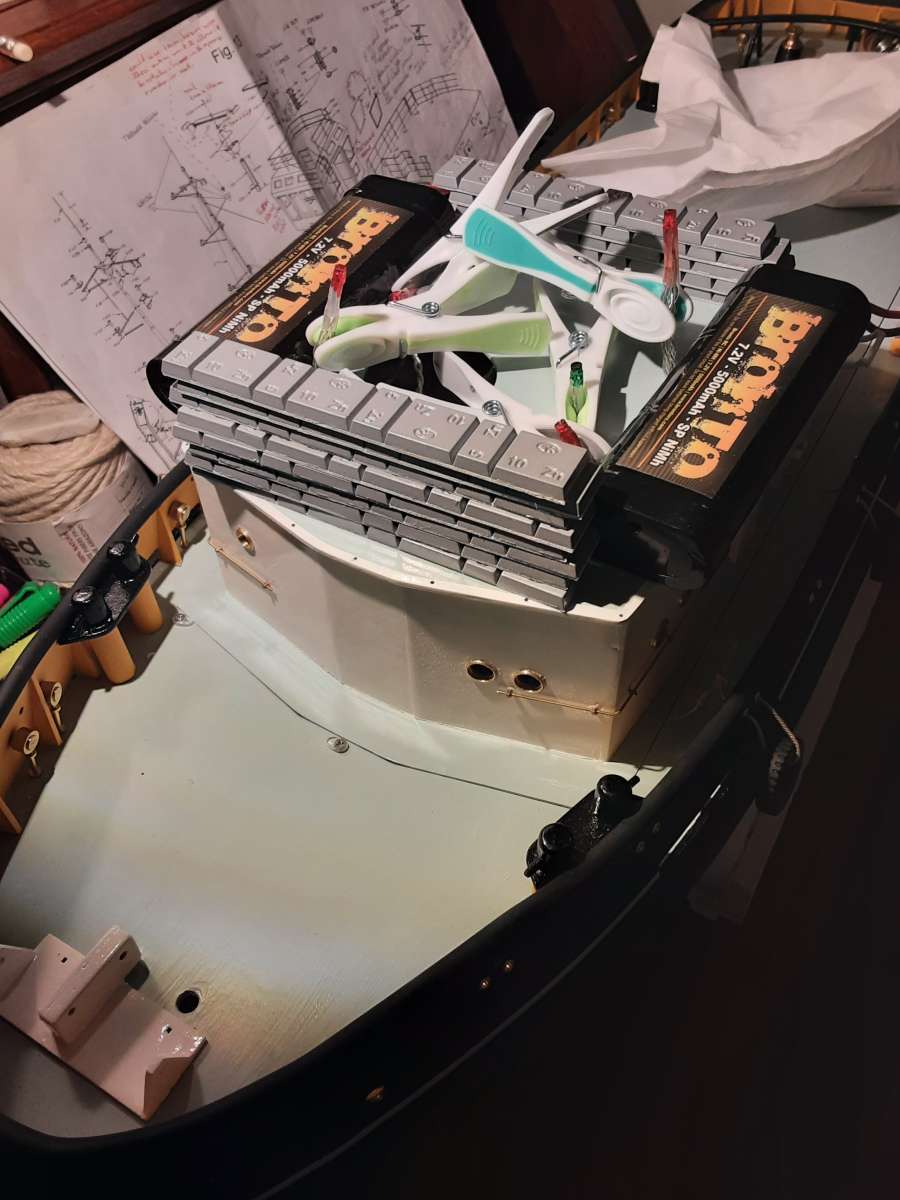

Having some trouble writing below photos…anyway, the crew quarters has no space left for the crew, it’s full of lighting wires and battery boxes. It is well illuminated so light shows through all the portholes.

Having some trouble writing below photos…anyway, the crew quarters has no space left for the crew, it’s full of lighting wires and battery boxes. It is well illuminated so light shows through all the portholes.

I

I

low here. One shows part of my clothes peg, wheelweights and battery collection. “You can never have too many….etc, etc.

low here. One shows part of my clothes peg, wheelweights and battery collection. “You can never have too many….etc, etc.

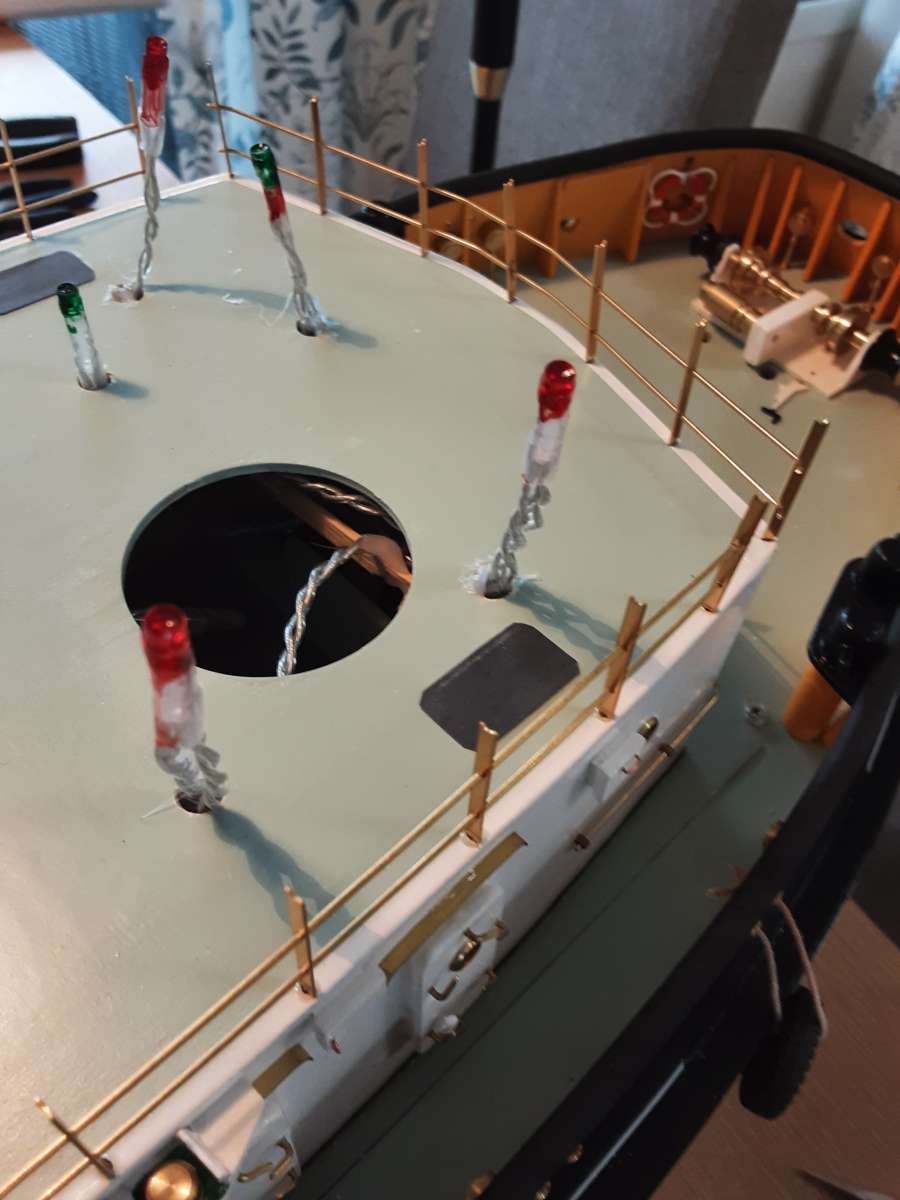

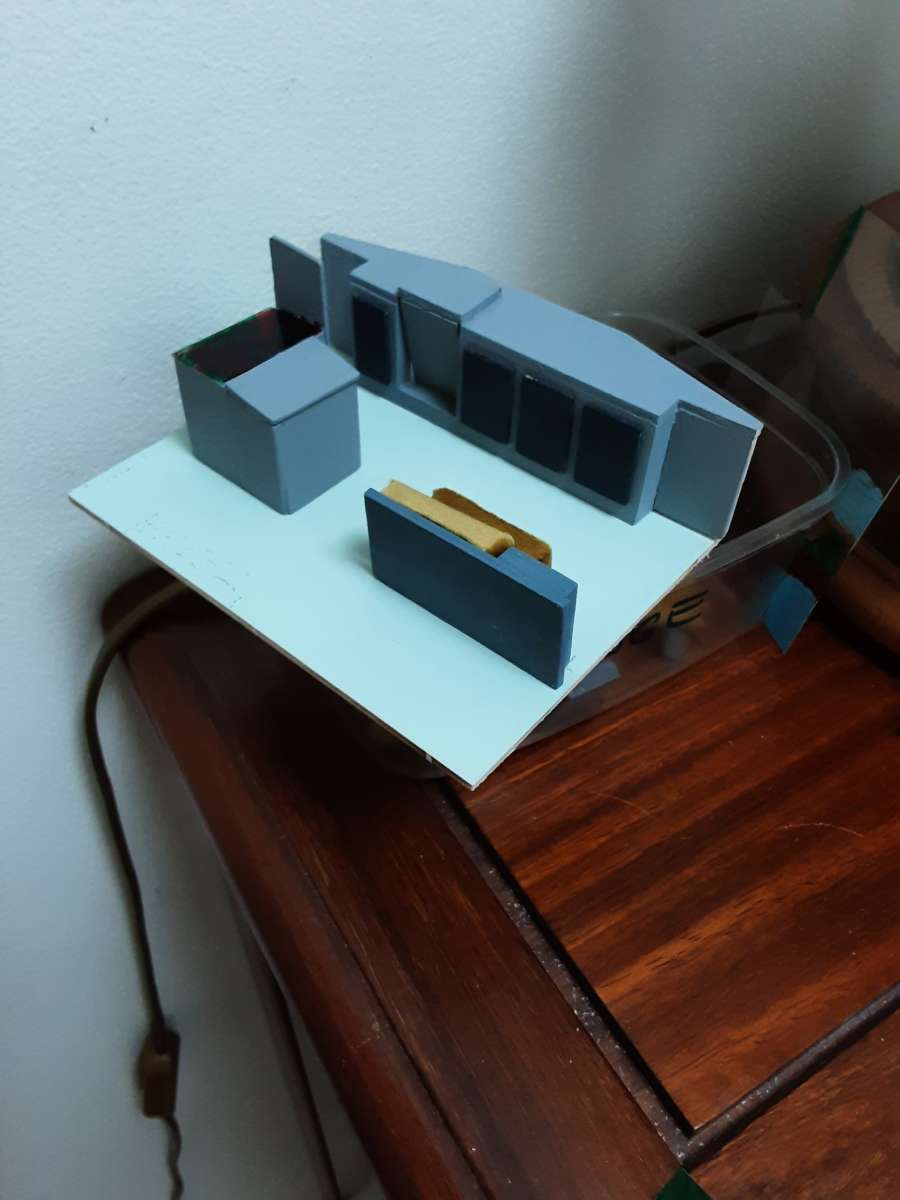

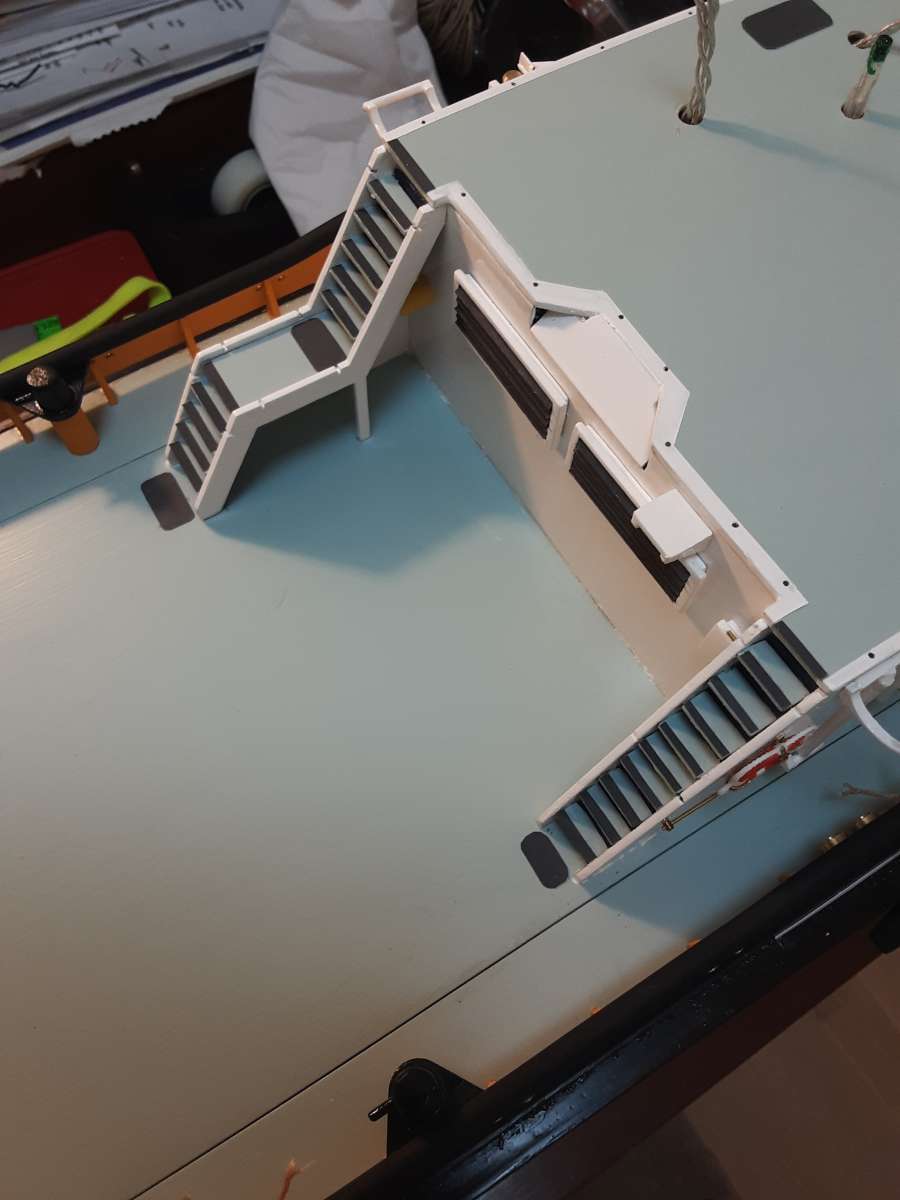

tion, but there’s the small issue of soldering to take into account. I felt that the Colin Archer was small at 1/15th scale, the Smit Ned’ is 1/33 and I notice the difference in the size of the detail!

tion, but there’s the small issue of soldering to take into account. I felt that the Colin Archer was small at 1/15th scale, the Smit Ned’ is 1/33 and I notice the difference in the size of the detail!