Water Pumps

Water Pumps

- This topic is empty.

Viewing 16 posts - 1 through 16 (of 16 total)

Viewing 16 posts - 1 through 16 (of 16 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Code of conduct | Forum Help/FAQs

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

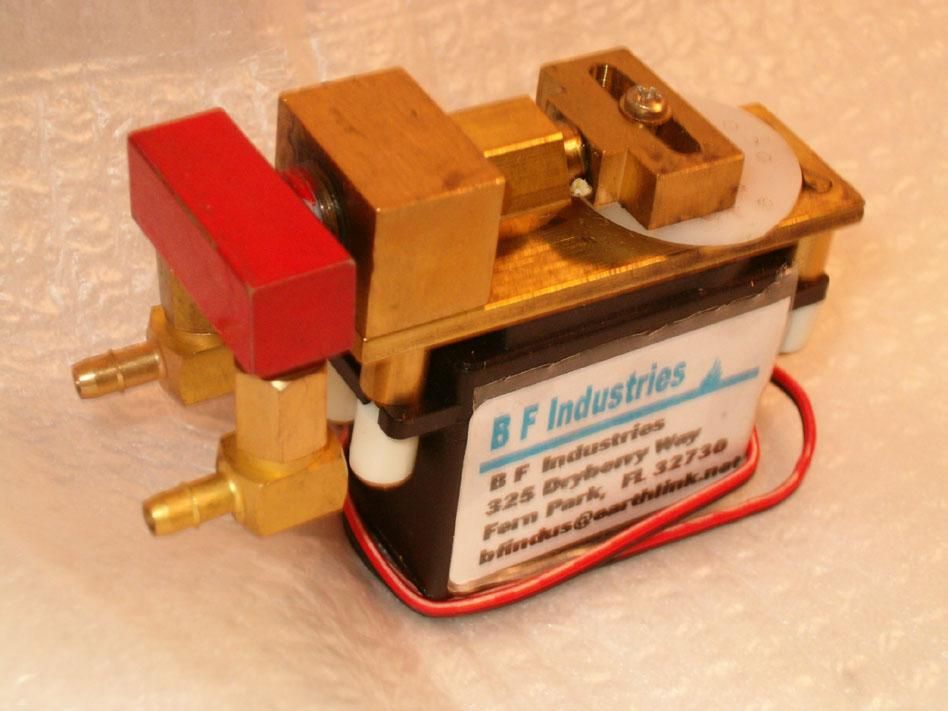

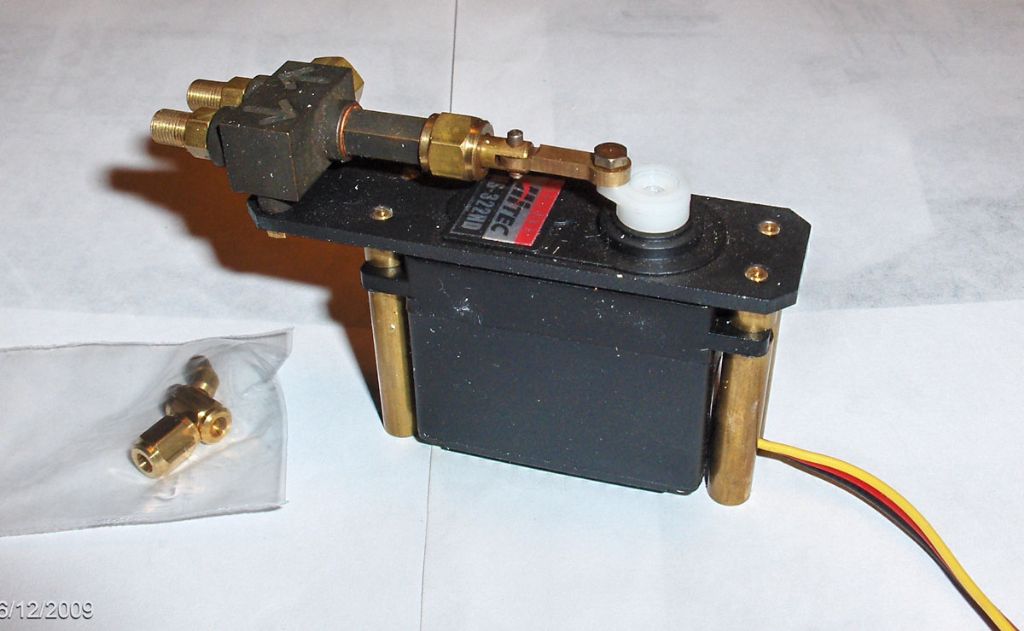

Hear is one that is avalable by Regner not cheap though also Ministeam do one in the uk

Hear is one that is avalable by Regner not cheap though also Ministeam do one in the uk