I`m amazed that the schools don`t teach woodwork, metalwork or handicraft anymore and haven`t done so for the last twenty years

What are they doing instead?….I ask myself

In view of this, I intend to show more of how to do things during the build…..Especially the important areas, for those members wishing to catch up on their lost school lessons!

In most stages of the build you must build accurately and no ……."That`ll do" methods!…….Unless it will, of course!

Also squareness, parallelism, symmetry and neatness are essential requirements

The usual measure twice and cut once still applies

If you can afford luxuries, buy some machine tools…..Bandsaw, Vertical drill, belt linisher, tool grinder…….and most of all ………..Goggles and quality dust mask

Back to work…

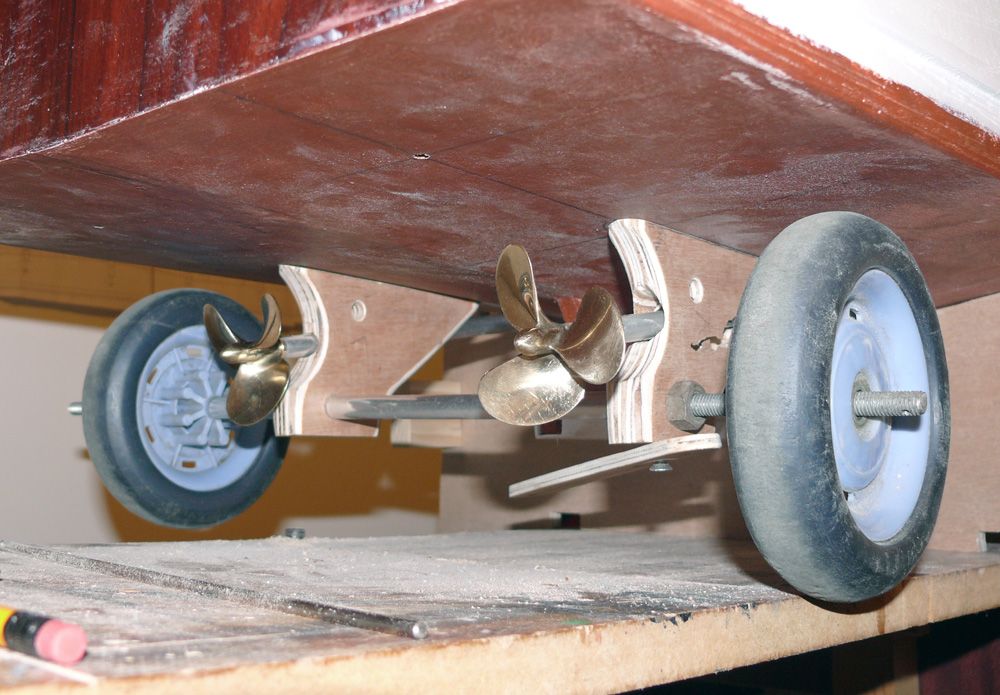

Setting the motor base to the required angle is very important and is quite tricky at times

I used to have a motto at work….." If a dimension is important……Make it adjustable"

In my case with the motor drives, I`ve avoided any glued fastenings……..All the joints are screwed or bolted

Just in case we find a snag………There`s one lurking round every corner!

Picture showing how the to check one of the many dimensions on setting the motor base

Using packers to get the ref for the deck level over the coaming lips, using a straight plank and ruler…..As opposed to the squinting eyesight method

The angle is obtained from the propshafts, making the motor surface parallel by measurement

This job has taken many hours……But well worth it!

Bob