Ok I have a very important question

I have to start considering materials to make the superstructure from and I have always planned on using 3 things

1.4mm Plywood 1.2 m square $120 already have 4 sheets

.5 mm Styrene available from suppliers in 2.4m x 1.2 meter sheets for $15.00

And Brass shim (etched)

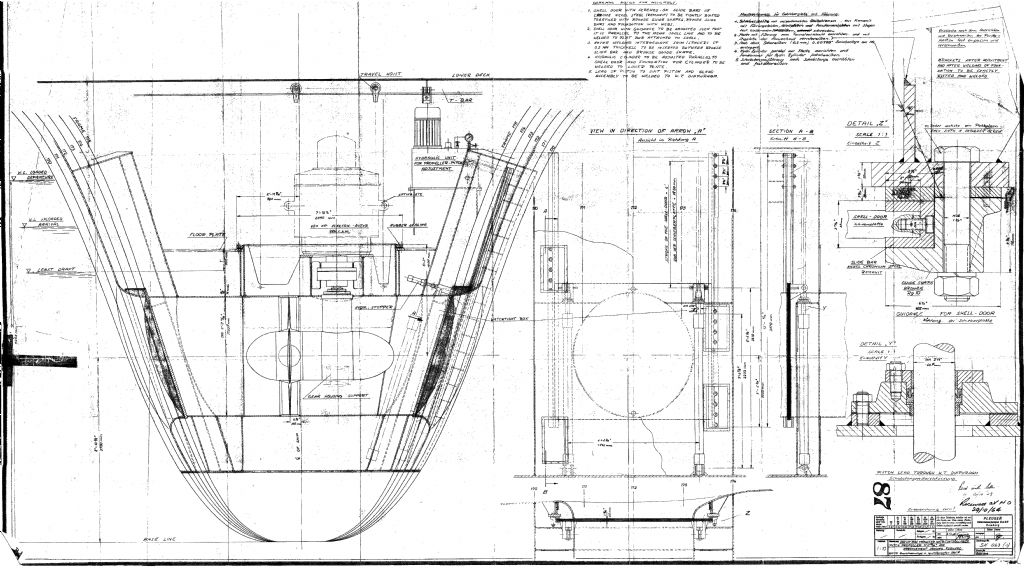

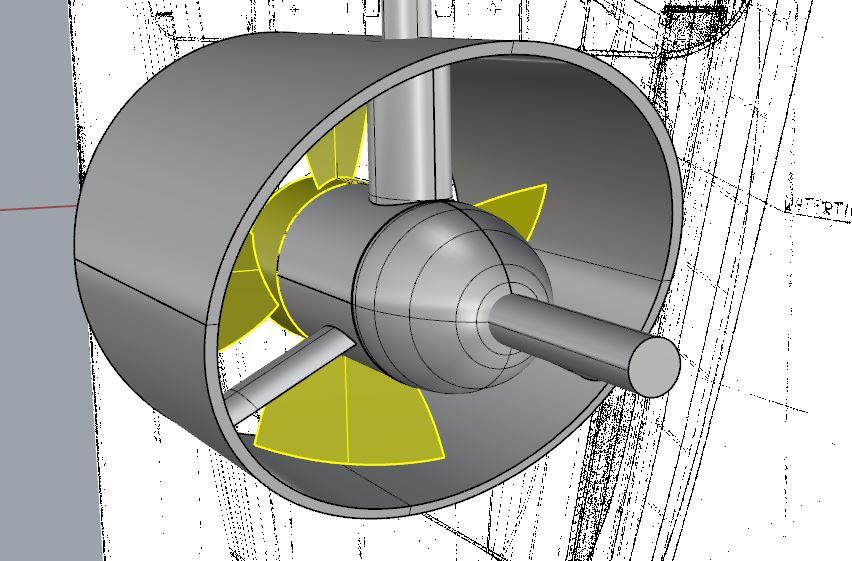

My intent has always been to make all the areas of the ship that have structure attached out of brass and solder the whole thing together, this is mainly for strength.

What thoughts does everybody have on this?

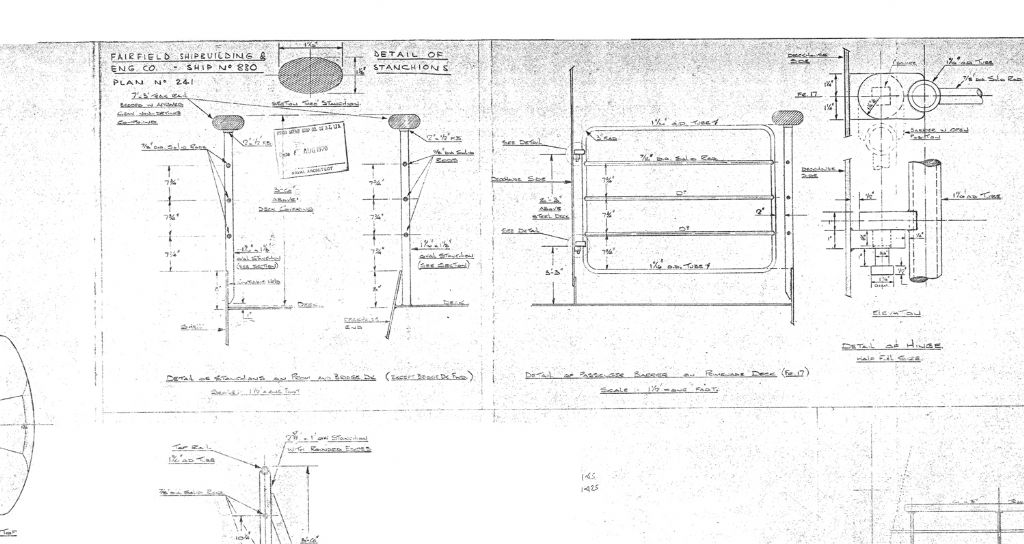

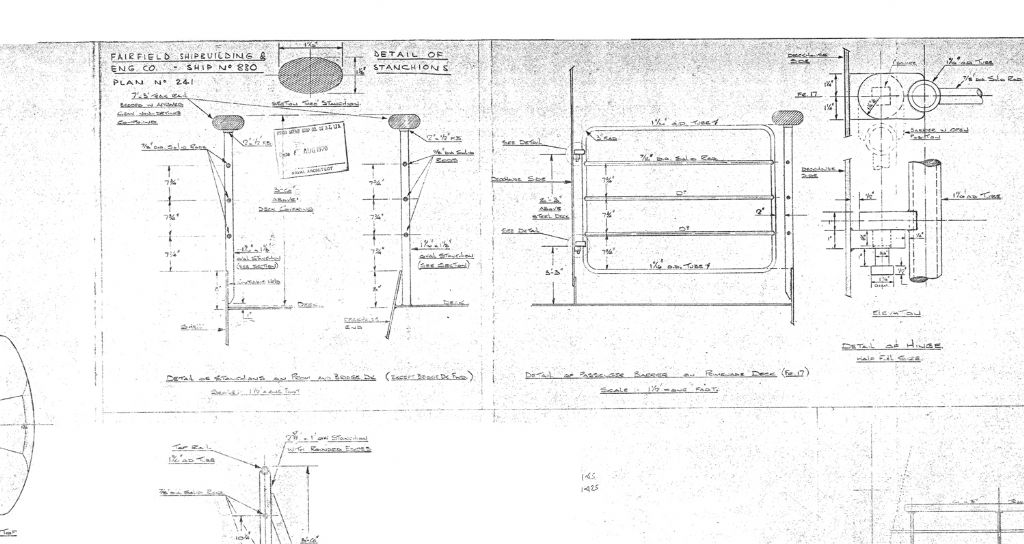

The upstands around the deck I am certain I wish to use brass as in the real ship the railing stanchions are welded to them and I can do a strong joint this way.

This of course means the upstand would have to have all the stanchions pre soldered on before being glued to model.

I would leave fibre glass on the hull short 10mm from edges to form a recess just about right for the thickness of the brass or styrene.

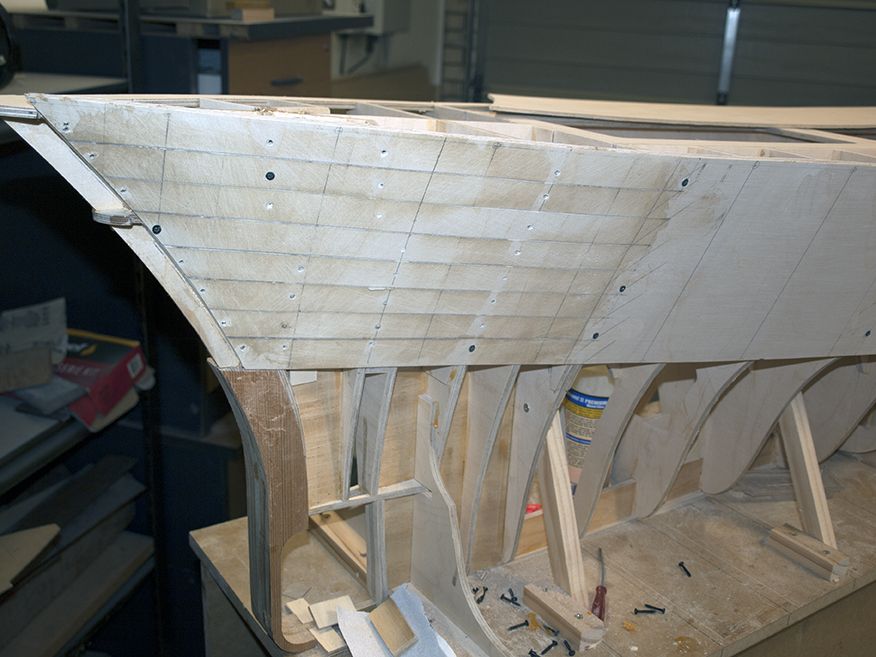

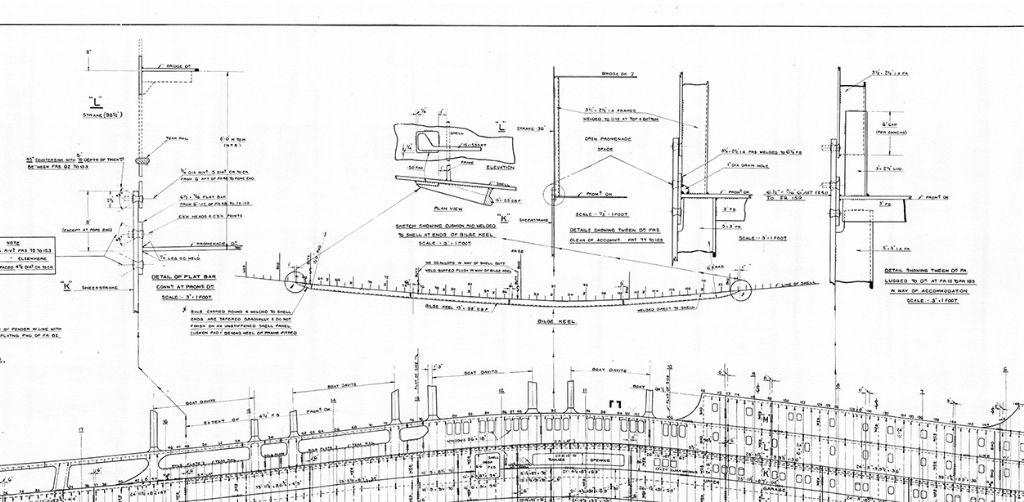

The 12'' gutter along the edge is steel the the deck is 1.5 inches on top of that made from Semprene Rubber

In this picture the arrangement is clearly shown.

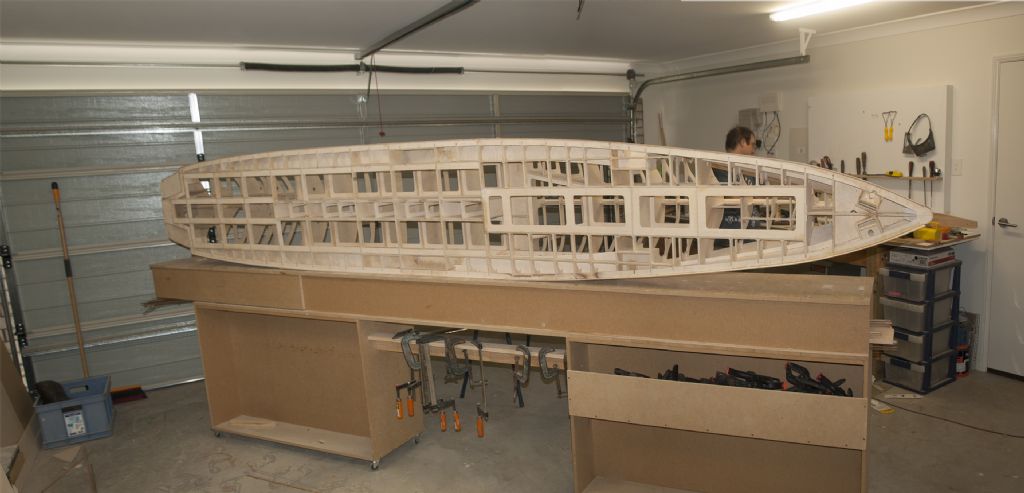

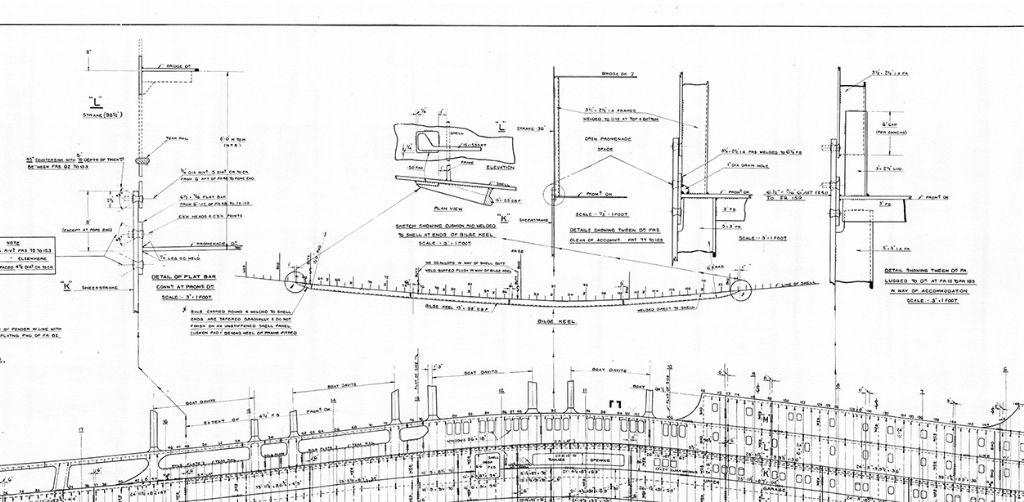

This is the other problem,I have 2 areas of the ship that are framed up in complex framing , this area shown below is the promonade and also the mooring decks aft are done in a similar way.

What do yo suggest for this? or do you think Styrene would be ok?

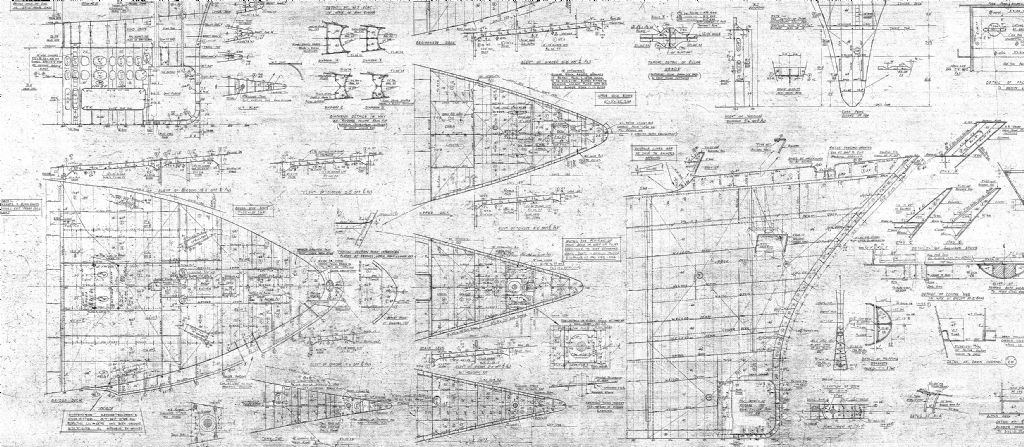

Luckily I have all the plans so no guessing about frame sizes and locations, all that is documented ,this is just about strength and the fact that it needs to be finished before being able to close it in.

I am thinking that the deck plating overhead here could be styrene and then the extra thickness for the rubber could be added via some other material that way all the frames and longitudinals can be easily bonded to underside.

Anyway would like to have a discussion about this with more experienced modellers.

Here is a part view of the shell expansion showing the way the superstructure is connected to the hull upstand.

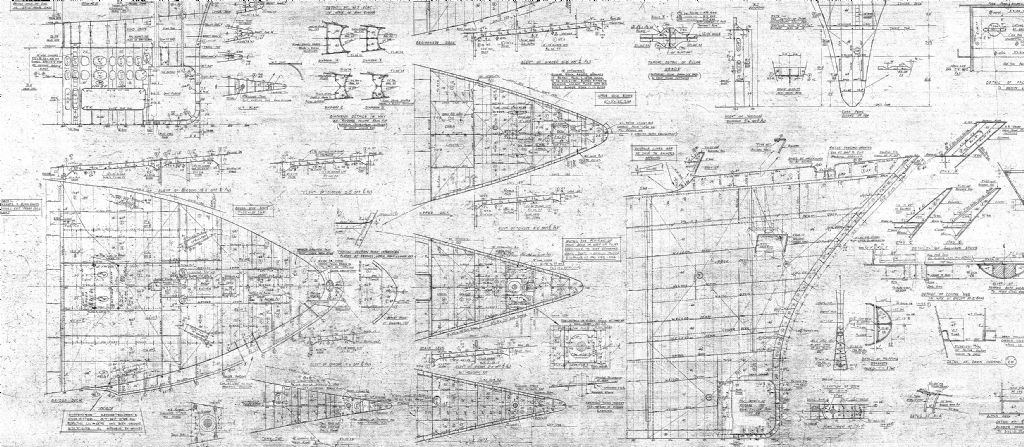

Also as you can see here the fore deck has a lot of nice structure that needs to be well made and strong.

Edited By Richard Dunn 3 on 15/12/2015 01:07:43

Edited By Richard Dunn 3 on 15/12/2015 01:13:44

Edited By Richard Dunn 3 on 15/12/2015 01:22:57

Ray Wood 3.

Ray Wood 3.