Thanks guys.

I really appreciate the help, I must confess I'm at a loss with this, I spent sooo long fixated on the fact I was using Styrene.

I look at models like that of Peter Davies-Garner that have successfully used Styrene to plate a large hull but the thing is they don't have the heat we do in summer.

I then hear people say Styrene breaks down over time, I have seen this first hand but only if not painted and only if in UV light for long periods, correct me if I'm wrong.

I have to admit when I said the plates fell off my other model I was using a good contact glue which is a mistake to be honest in warm climates.

The epoxy I use is one that is a staple of the joinery industry here in the lower hemisphere and it is an excellent product, it never lets go and I have glued all sorts of metal to wood with it in the furniture industry for years with no problem but again how much movement am I going to get bonding a average 50mm x 250mm plate .6mm thick to a fibre-glassed surface, that's a thing to remember as well its not raw wood but glassed.

Aluminium was a suggestion made by another modeller that had not considered the scale of mine, I have designed and built aluminium boats in the past so am aware to a degree of the problems of expansion however I had assumed that due to the thin nature of the Aluminium it would not be an issue if I left .6mm gaps between the plates for the weld seams which in turn had some give in them.

I'm almost contemplating making my own epoxy resin/paper concoction (like Formica without the high pressure) but it's a LOT of extra work.

It's a puzzle no doubt about it, but I am adamant I am plating the hull somehow.

By the way this is only a fresh water model, it was never intended to be in salt water.

I translated that Swedish site and read it, that's exactly the look I want but of course welded,

I just had a thought I might try, plating it in sections along the length as per expansion plan BUT every 4th plate in .5mm ply to absorb some of the movement.

I might need to try this.

Back to the drawing board.

I

Edited By Richard H Dunn on 29/05/2017 08:13:19

Edited By Richard H Dunn on 29/05/2017 08:14:56

Ray Wood 3.

Ray Wood 3.

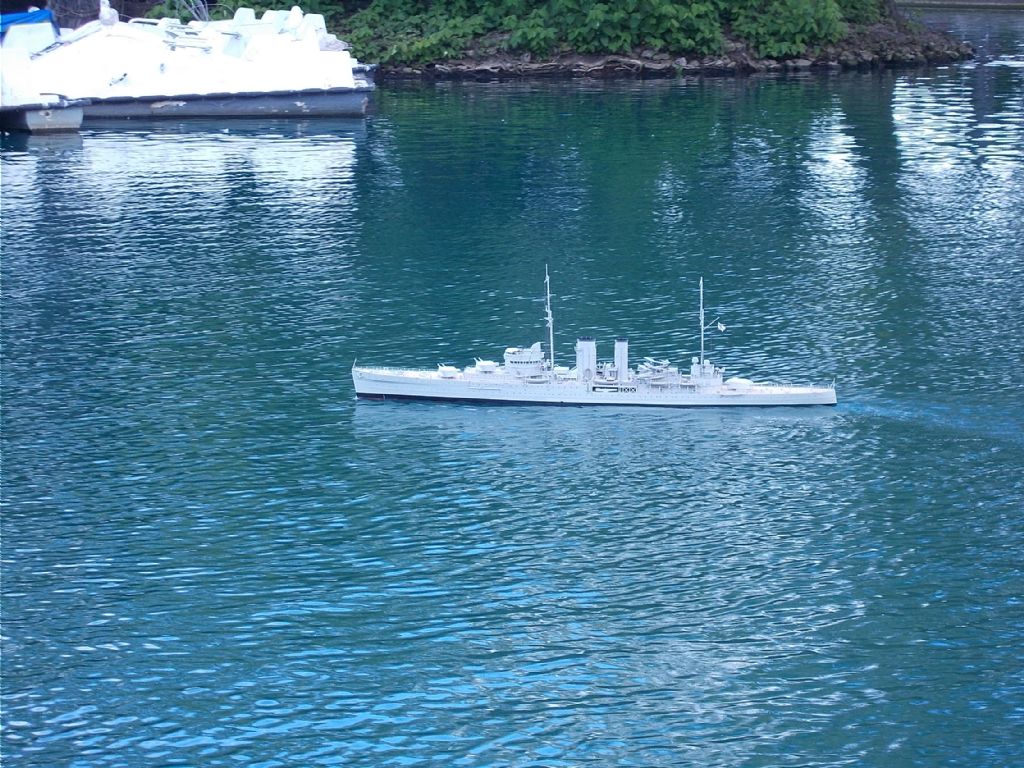

– why do we really need to apply plating to the side of the hull and also assimilate the rippling. The reason I ask that I spent a lot of time researching the plating for HMS Exeter – then I applied the plating to the hull using styrene sheet. It took me a long time to get it right. When you have a couple of coats of paint on the model it becomes less visible and, if you stand say 2-3 feet away – you can just making the plating out. When I sailed the model on the lake – one had no idea at all that it was plated. It was only when the model was on a stand and people were asking questions about it and I was pointing it out that they realised. So, can you see what I mean? If your model is going to spending a lot of time being viewed by the public and out of the water, yes, it will be worth the effort. But, if it is going to live its life as a 'normal' model – i.e. in and out of the water and enjoy the sailing of it – it may not be worth going to the effort of detailing the plating/applying plating

– why do we really need to apply plating to the side of the hull and also assimilate the rippling. The reason I ask that I spent a lot of time researching the plating for HMS Exeter – then I applied the plating to the hull using styrene sheet. It took me a long time to get it right. When you have a couple of coats of paint on the model it becomes less visible and, if you stand say 2-3 feet away – you can just making the plating out. When I sailed the model on the lake – one had no idea at all that it was plated. It was only when the model was on a stand and people were asking questions about it and I was pointing it out that they realised. So, can you see what I mean? If your model is going to spending a lot of time being viewed by the public and out of the water, yes, it will be worth the effort. But, if it is going to live its life as a 'normal' model – i.e. in and out of the water and enjoy the sailing of it – it may not be worth going to the effort of detailing the plating/applying plating