Hi Jim,

Here are the promised photos.

The first one shows a sail arm winch in a gaff rigged ketch that my wife restored about 4 years ago. There are two sheets running aft to the mizzen and main sails. I used a short length of 1/8 brass tube, gently bent to an approximate right angle as a guide for each sheet to come up through the deck.

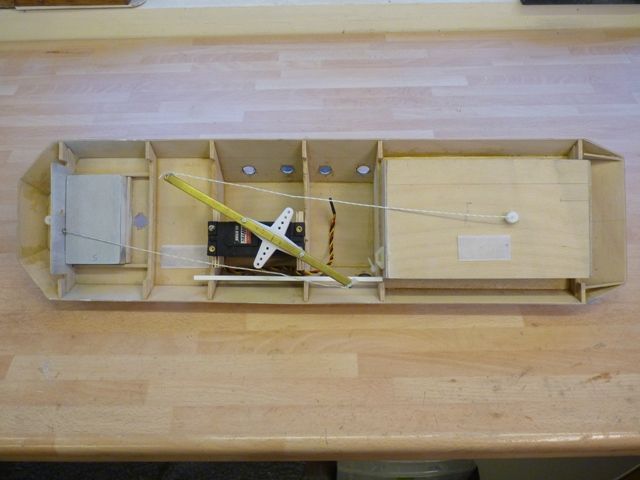

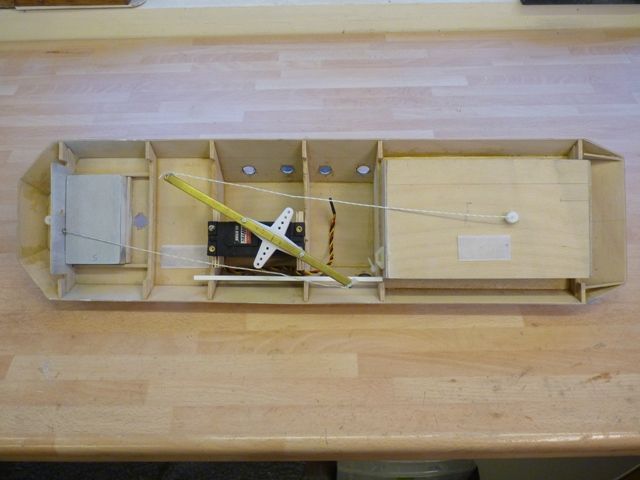

This one is Scotsail which is slightly unusual in that the sail arm winch is mounted uupside down in the cabin superstructure which is all removable in one piece. You can see the servo arm has been extended as I described in my earlier post, one side controls the main sail and the shorter one the jib. It works very well as a sail control mechanism but is hopeless as an overall installation as the sealing between superstructure and cabin is not good enough. When the yacht heels over the hull soon accumulates a lot of water. This model is about to be revamped back into a more conventional yacht with the sail winch in the hull and a proper sealed hatch.

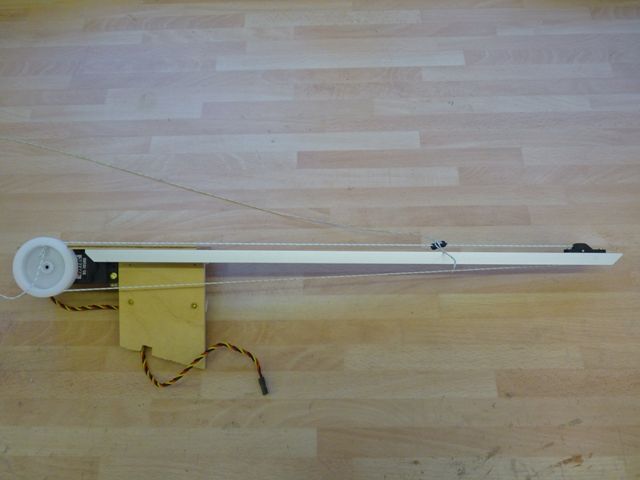

This one is work in progress for an 80 year old yacht that Elizabeth is currently restoring. It is designed to be completely assembled on the bench and then fitted into the hull through an oval hole about 5 inches by 3 inches. The ply plate with a small cutout at the bottom will be the attachment to the keel.

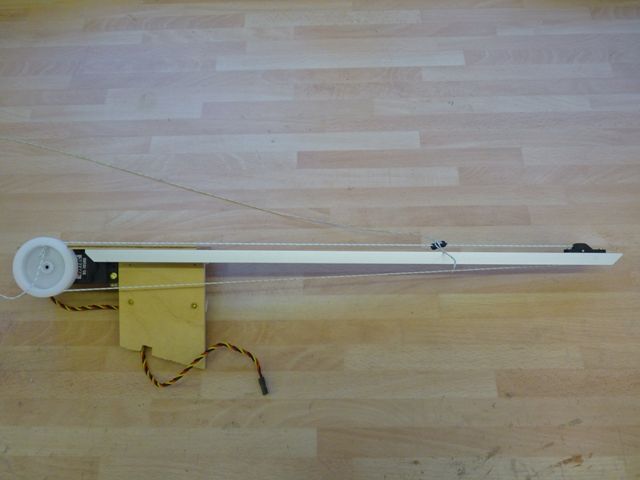

Here is another view showing the aluminium arm and return pulley, which is a Nylet supplied through deck pulley. I usually attach the sheets to the loop using a three hole bowsie which you can see towards the right hand end of the loop. Because the sheet will exit the hull behind the winch there is a risk that the sheet might drop on to the drum of the winch and get tangled. I plan to fit a thin sheet of styrene to the top of the ply mounting plate to shroud the drum. I also need to chamfer the edge of the ply plate so the bowsie cannot snag on it as it gets pulled towards the drum. All these detailed aspects of the design are much easier to implement on the bench rather than working blind through a small hole on the deck. With a Thames barge you should have plenty of access though.

Here is a final view of the servo mounting plate. The radio receiver, battery and servomorph will be mounted on the top of the plate. In this installation I need to limit the travel of the loop to no more than 400 mm because I cannot get an aluminium arm any longer than this through the hole in the deck. It also better matches the length of the main and jib booms on the yacht.

If you have any more questions just ask, there are lots of people on the forum who are very knowledgeable and keen to help.

Gareth