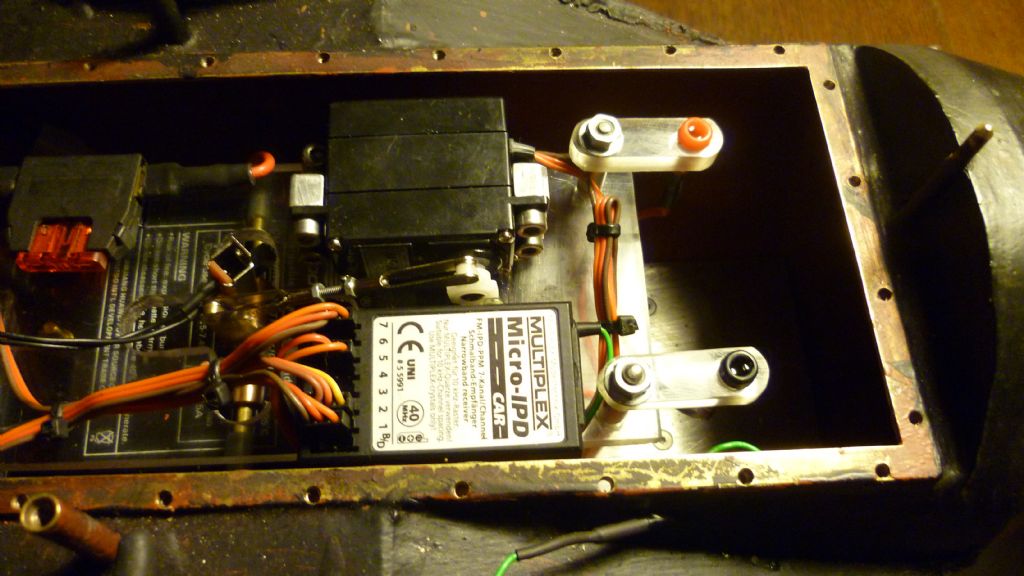

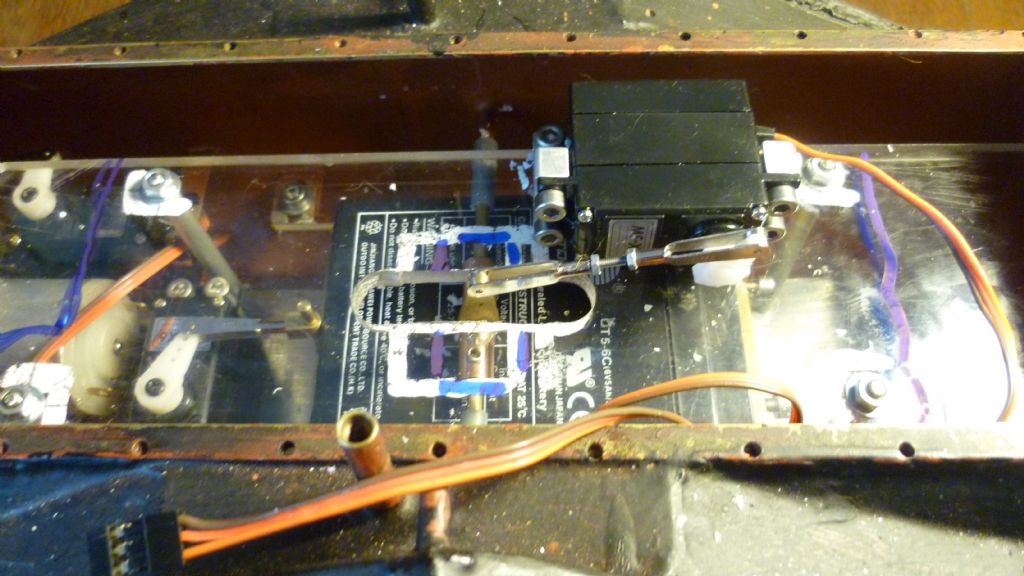

Hi Everybody, been doing some extensive bath trials over the past week and here are the results. The motor (545) and prop combination are well on top of the job. At full welly she takes off like a speed boat so I'm happy to have that reserve of power if ever needed. It's hard to assess in a bath but the rudders don't seem that powerful despite having over 45 degrees of movement. The main focus was on getting the static ballast correct. Her ballast tanks were rigged with a simple bleed pipe:-

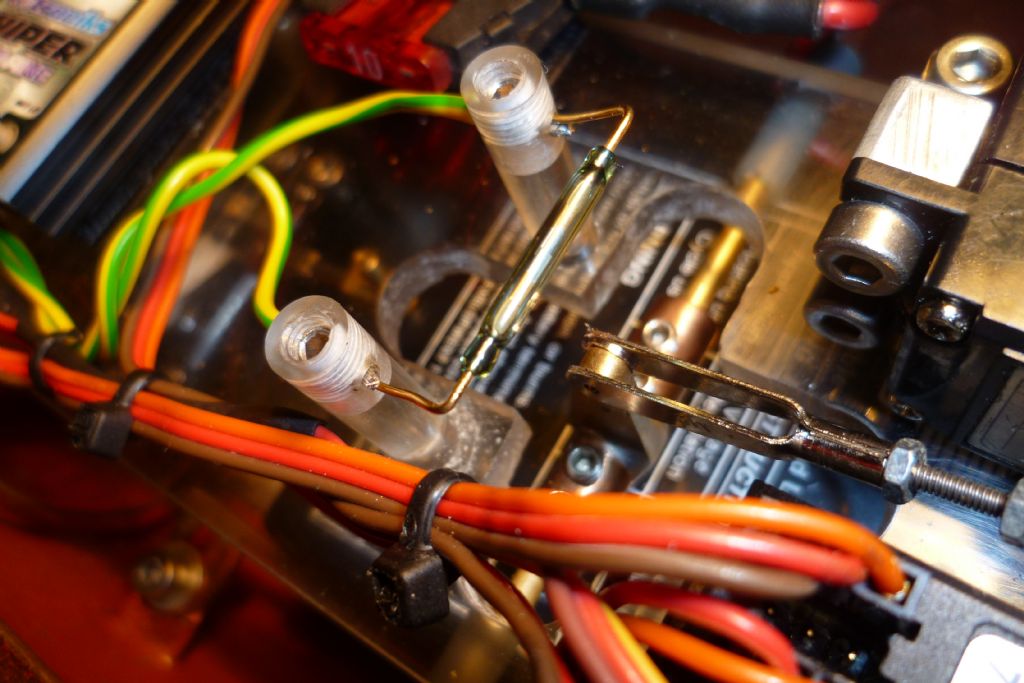

At full vent they took her down about an inch so more keel weight was needed. This was found by piling bits of the famous lead pipe on top of the hatch:-

All the lead bits were then cast into one lump and screwed onto the main keel so it sits inside the ballast tank cavity.:-

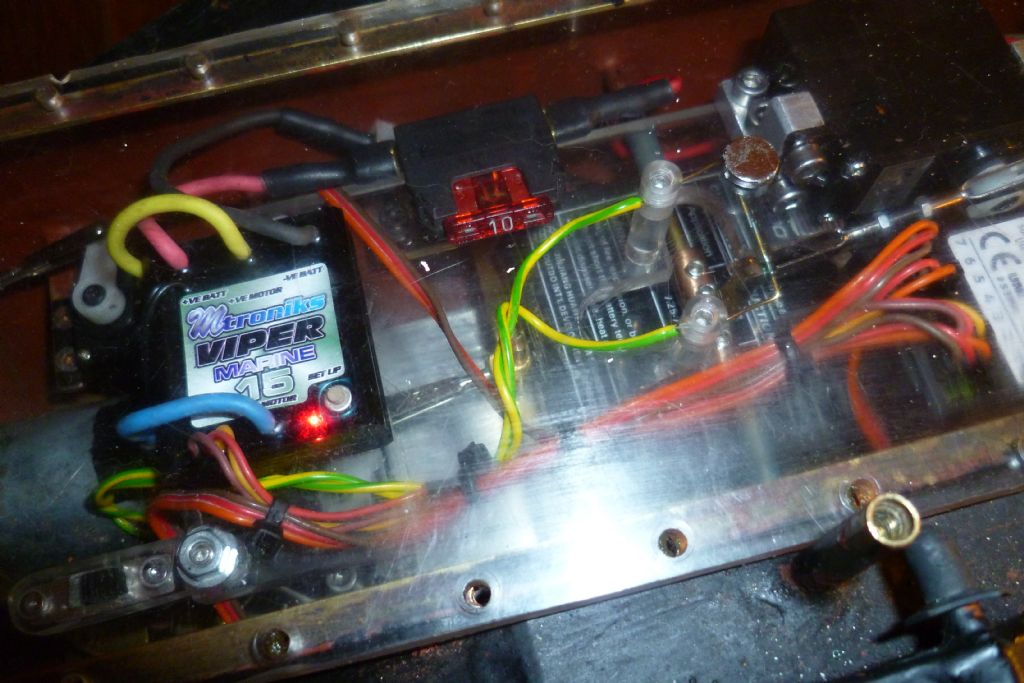

This added about another 500 grams to the keel weight. Some final trimming was needed to get static fore and aft correct:-

and this was added to the internal battery. Being able to shift the battery fore and aft with the RC gave about half an inch of adjustment in fore and aft trim.

At the end of all this ballast work the ballast tanks themselves would take her down or bring her up so I am very happy about being in a 'control zone'.

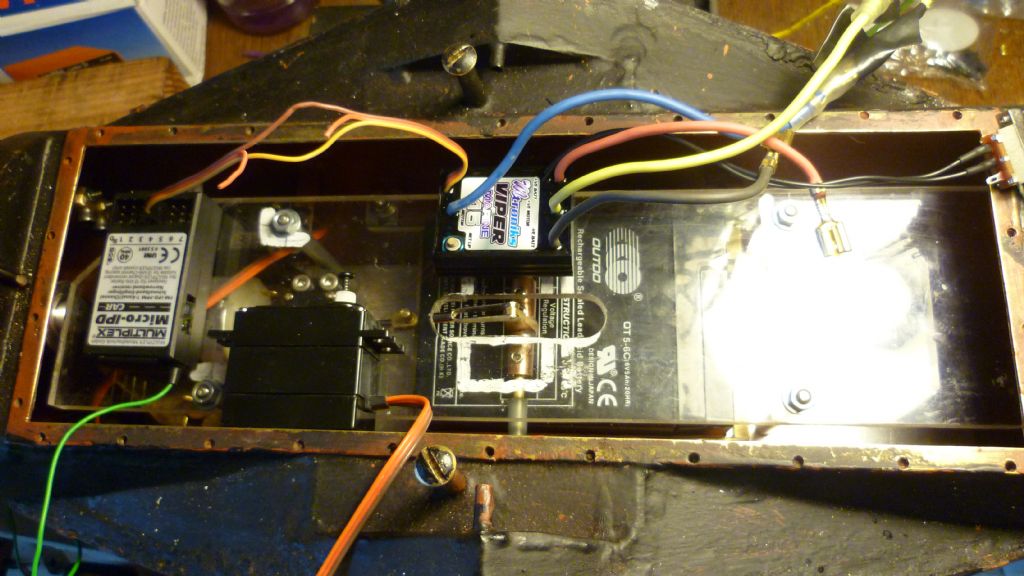

Mi next problem was the issue the issue of neutral buoyancy. Resurgam's water line is at the top of her hull and exactly at the bottom of the breakwater plating protecting her 'conning tower'. The real boat herself would have had no more buoyancy than say a 45 gallon drum (all approximate but about 450 lbs). No wonder the contemporary reports state she was submerged for most of the time!

On mi boat I needed to get some buoyancy into the superstructure which other wise was dead weight. Two bits of poly foam were added:-

This gave some 80 grams of flotation and kept her rock solid on her water line.

Given full pelt in the bath she was actually starting to dip under with the hydroplanes down but there's not enough room to make any real judgement.

When she came out of the bath there was one drop of water inside the hull. Literally no more than a mustard spoons worth. I suspect this came up the prop shaft as the seals had to tolerate no end of abuse during the shortening process.

Way ahead? New prop seal, consolidation of all her fittings and then chuck her in the pond!

Len

It looks all but complete.

It looks all but complete.