Hi Everybody,

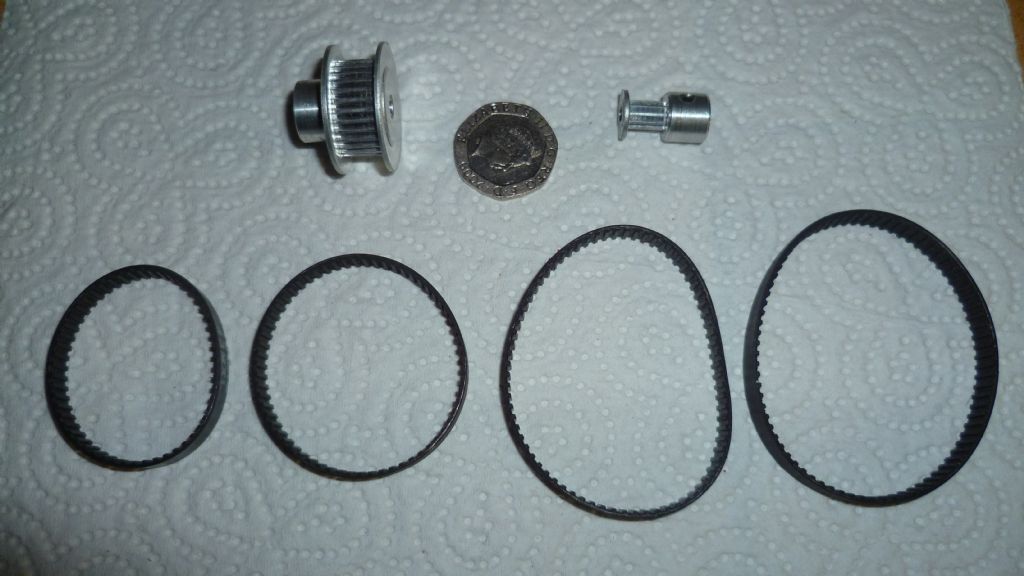

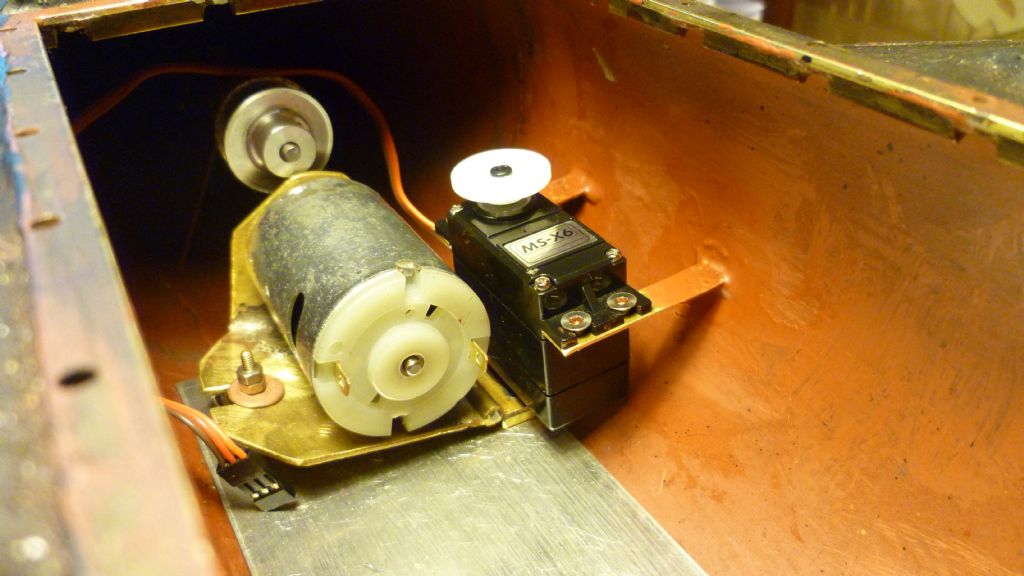

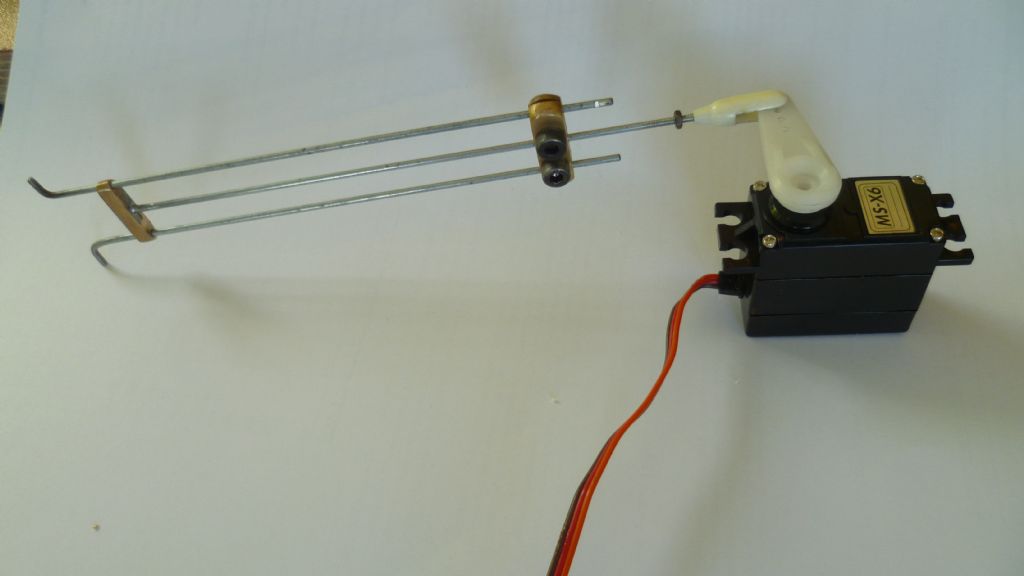

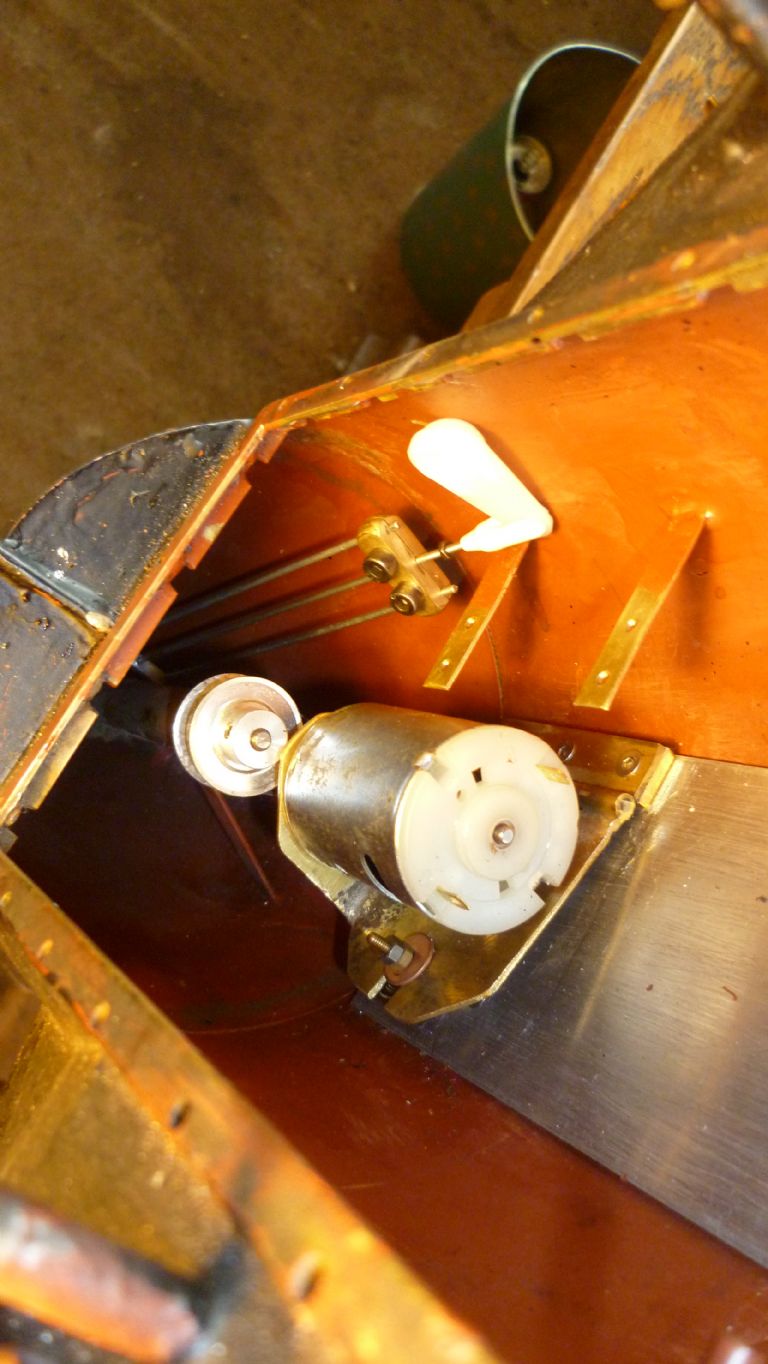

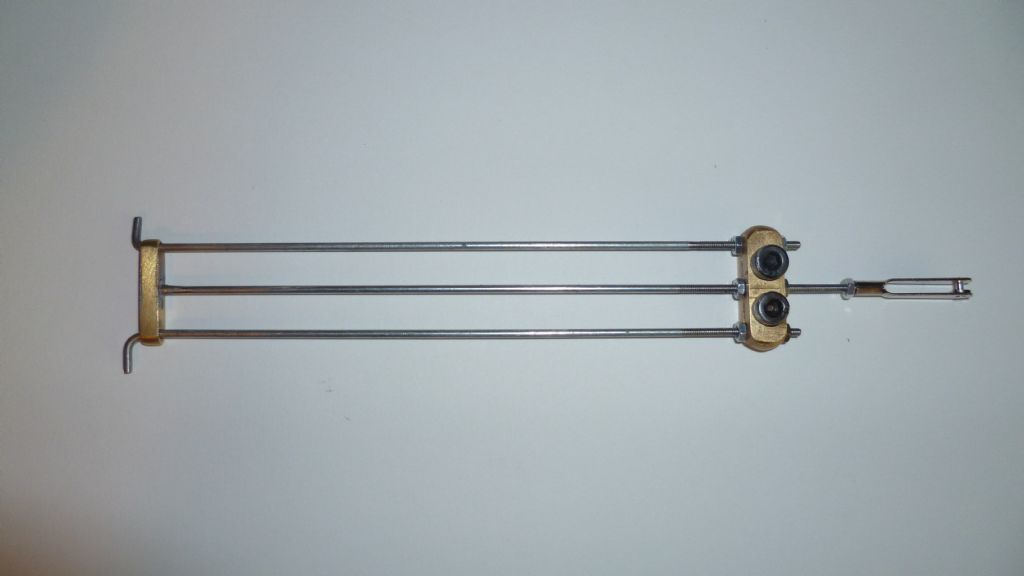

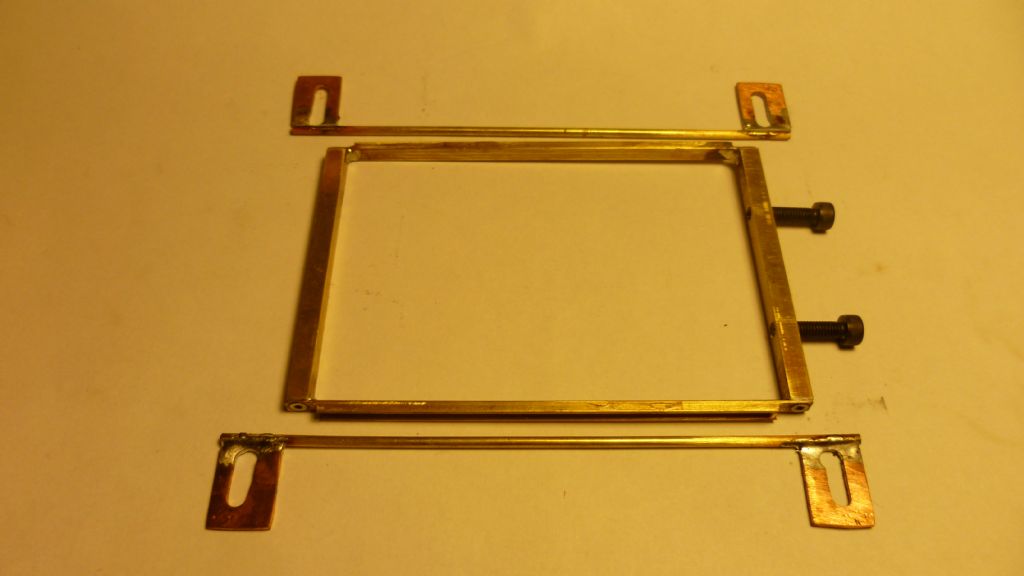

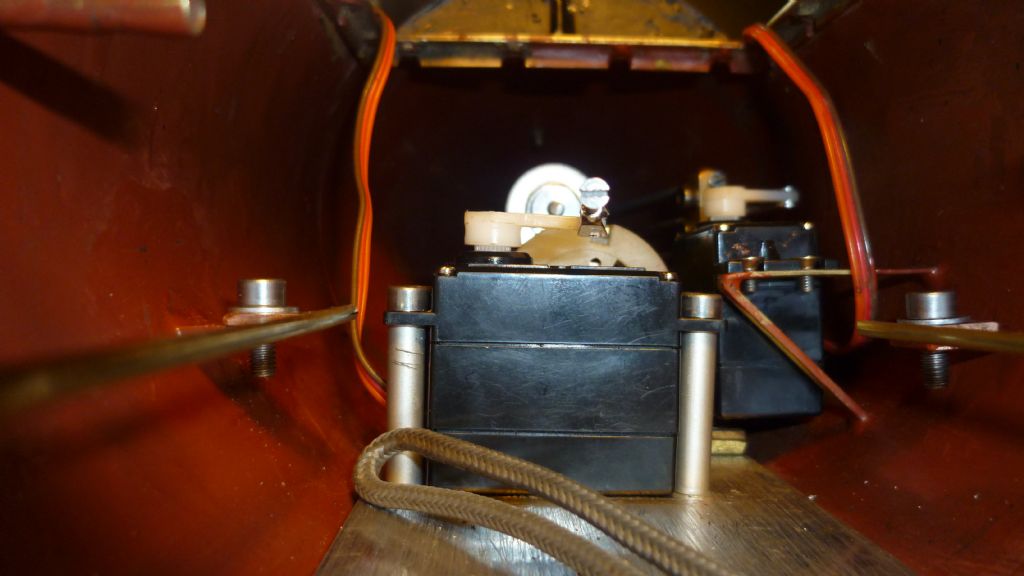

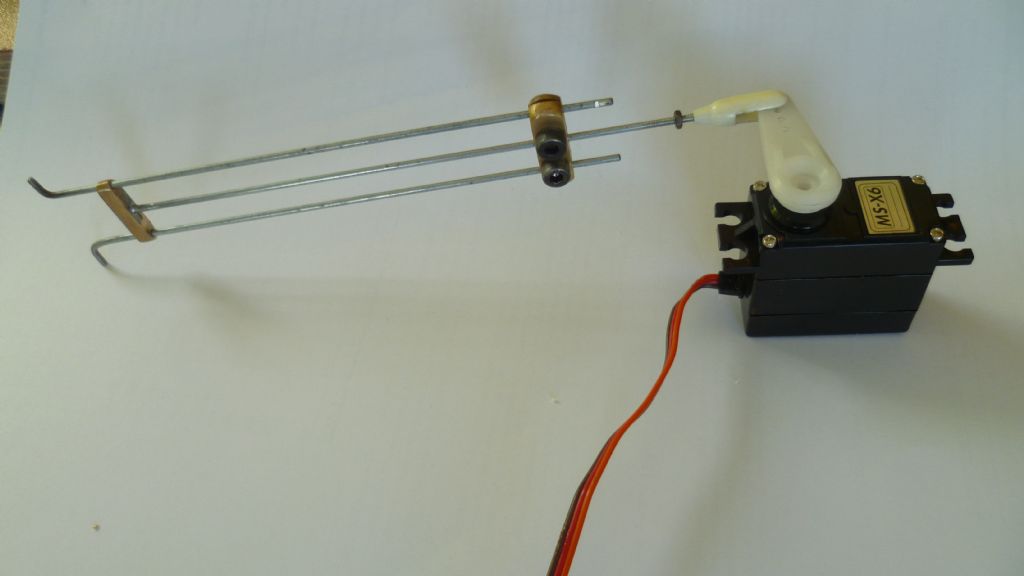

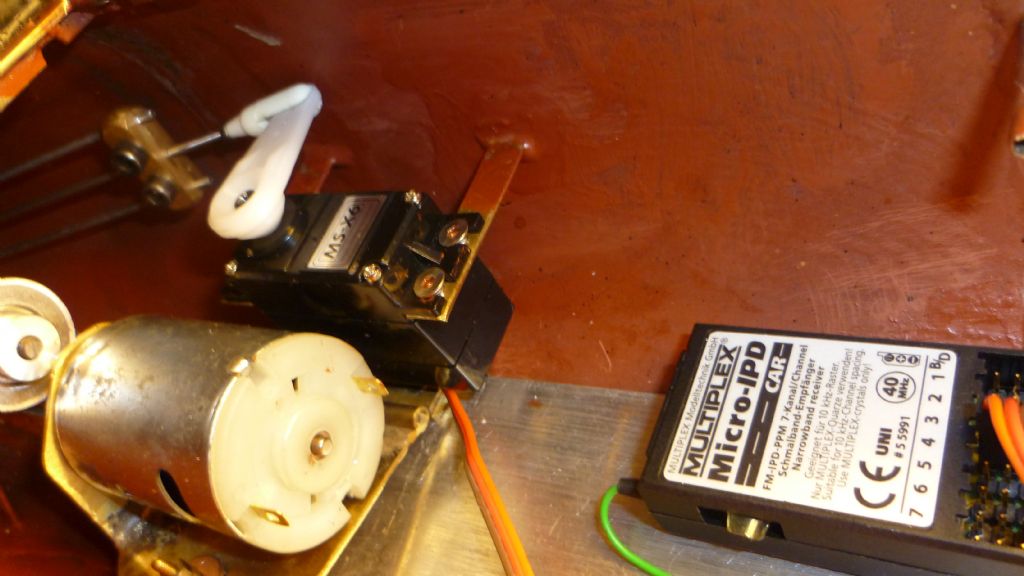

We now have rudders that waggle! It was a bit of a job and took some working out. Pic one is just a recap of the control rods to be installed.

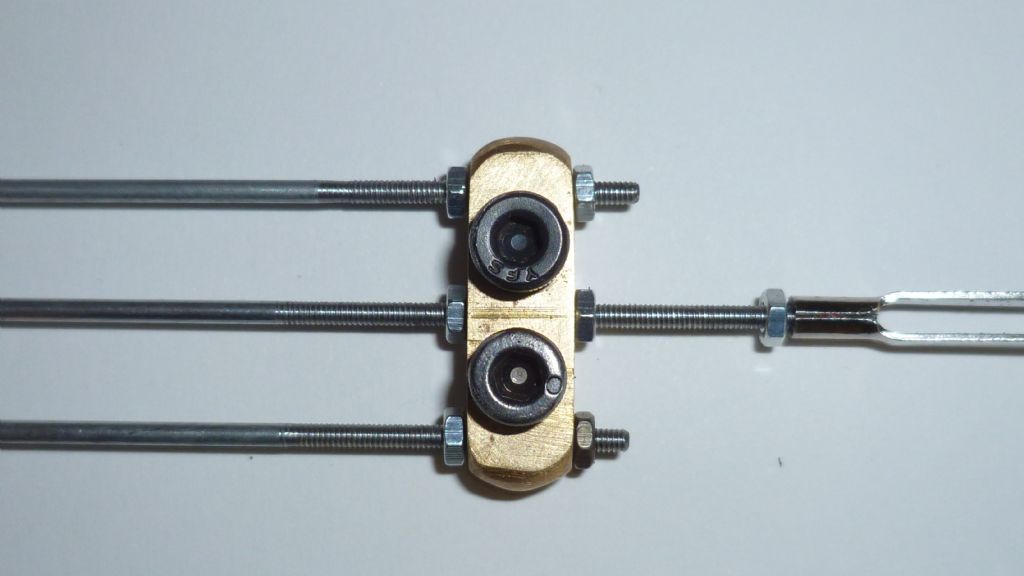

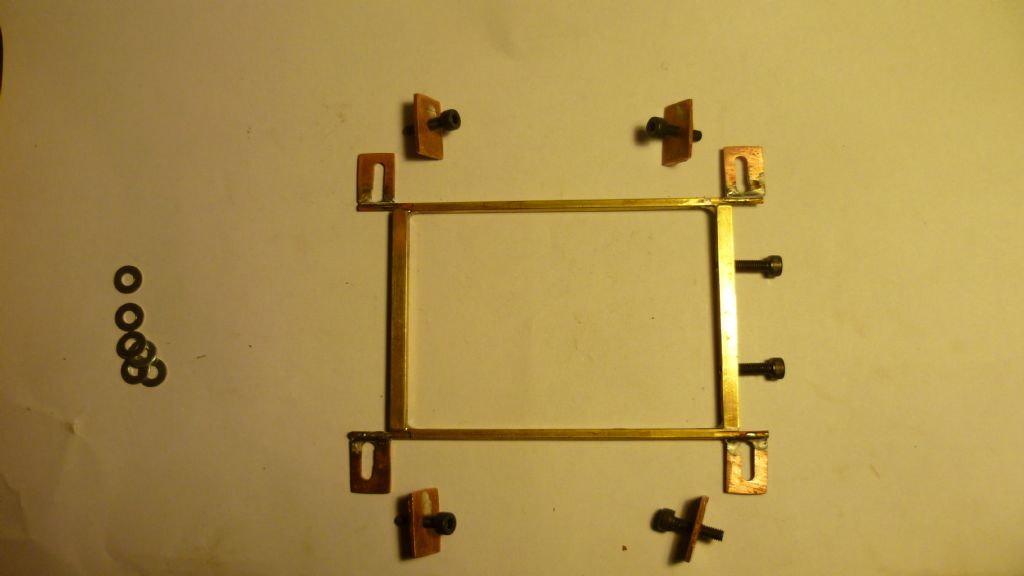

Each rudder shaft is kept in place by the central keeper rod. The clamp keeps everything rigid once it's all in place. It became obvious very quickly that the only way it was going to get installed was with the hull vertical and lots of light to see what was going on. The next pic shows mi boat rubber banded to the stand and the whole thing vertical, stern down.

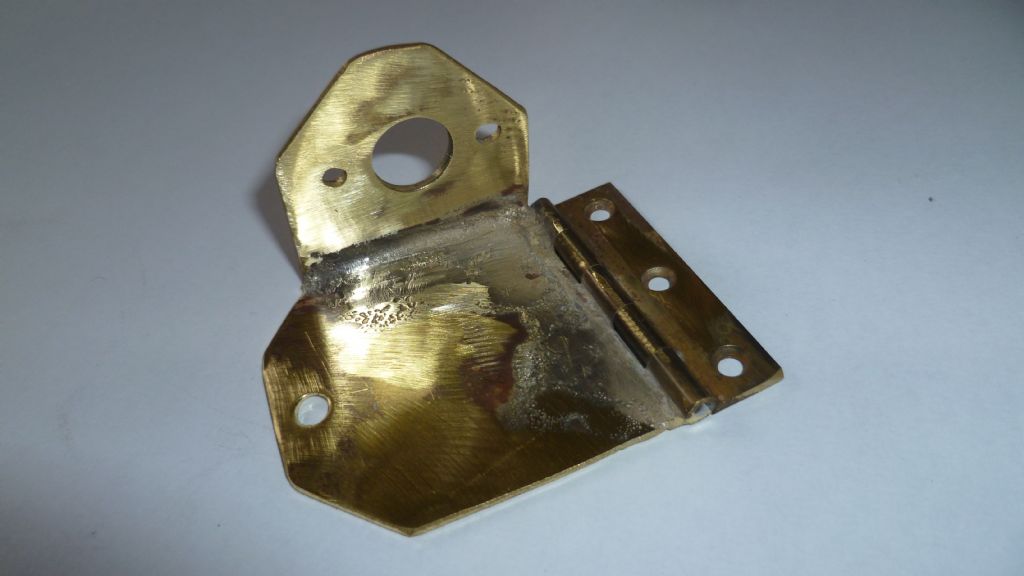

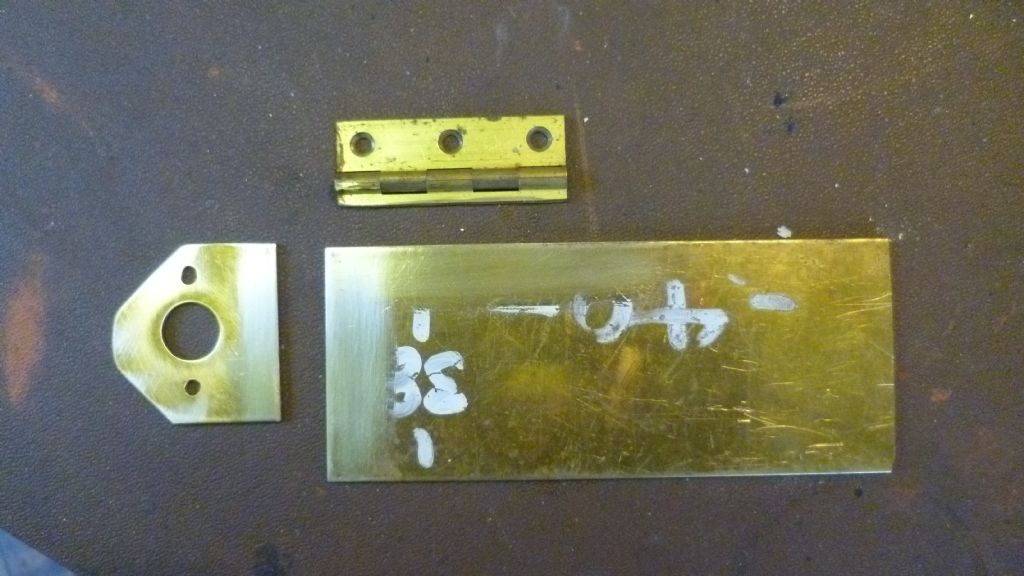

Each rudder arm control rod was poked down to the stern and hooked in place. This proved quite difficult when they were cut to their correct shorter length and needle nose pliers didn't really help. The answer was to slide a bit of 2 mm bore brass tubing over the rod to extend its length for easy handling. The tube was ever so slightly bent so that it gripped the rod but could be easily slid off after the rod was in place. The rods had to be kept in place while the central keeper rod was slid into position and eventually this was done with a bit of foam rubber.

This allowed to rods to be moved about while the keeper was slid on.

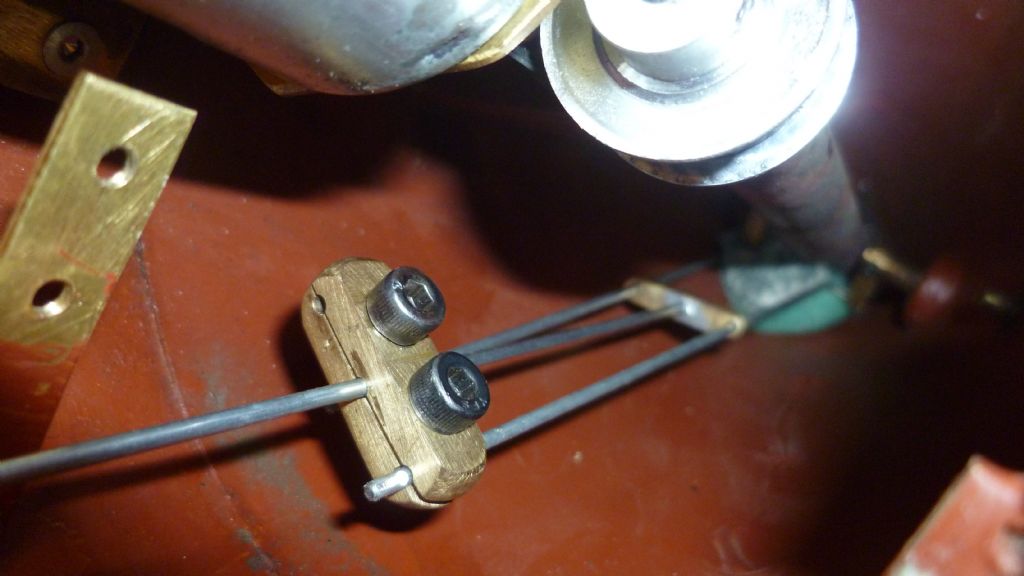

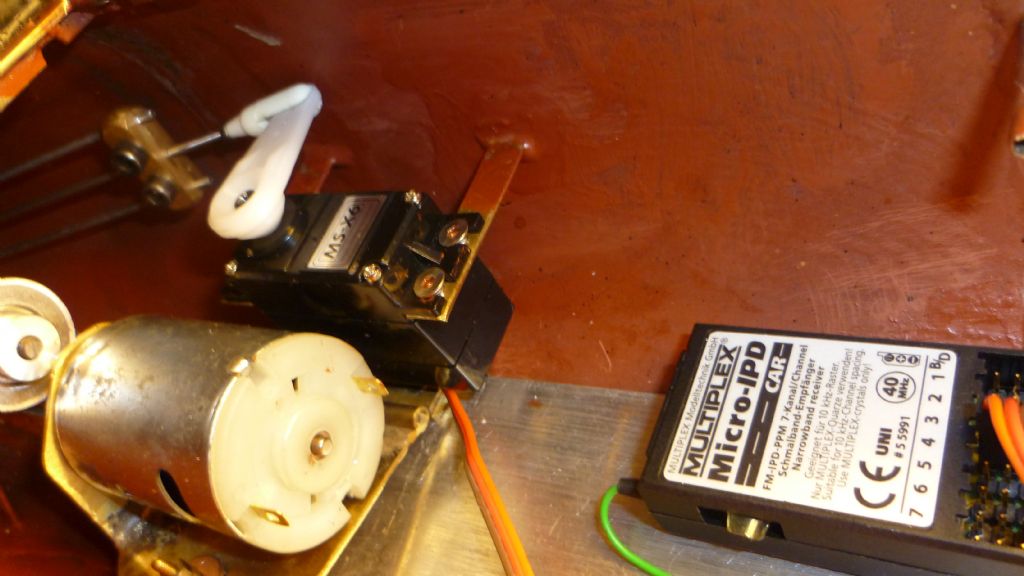

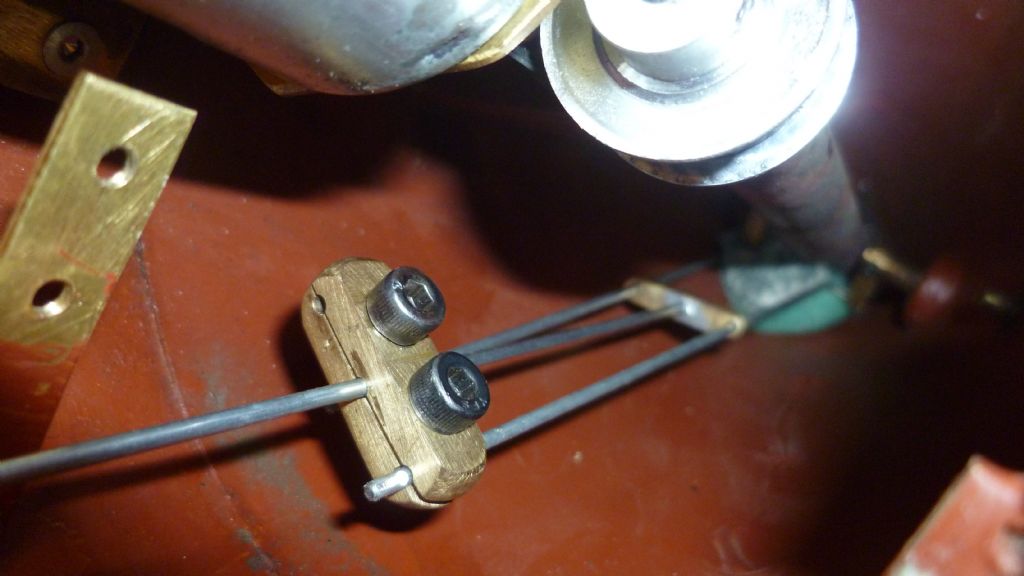

Next the clamp was slid on………..

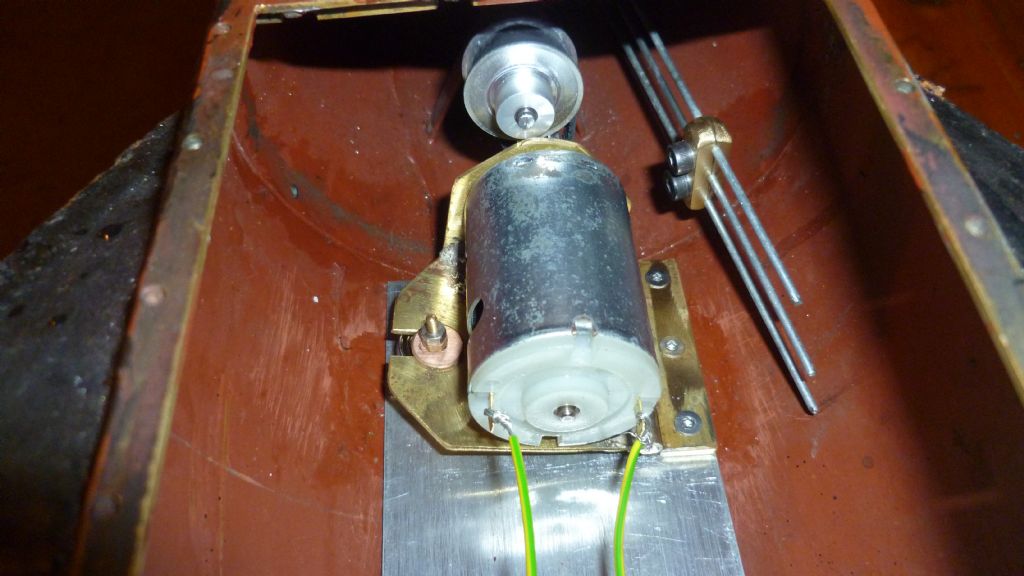

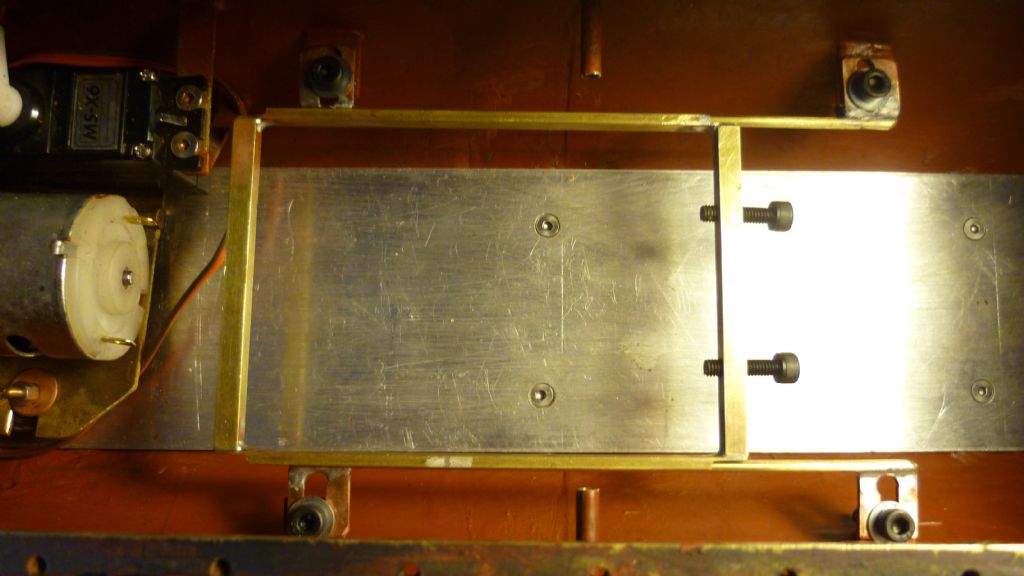

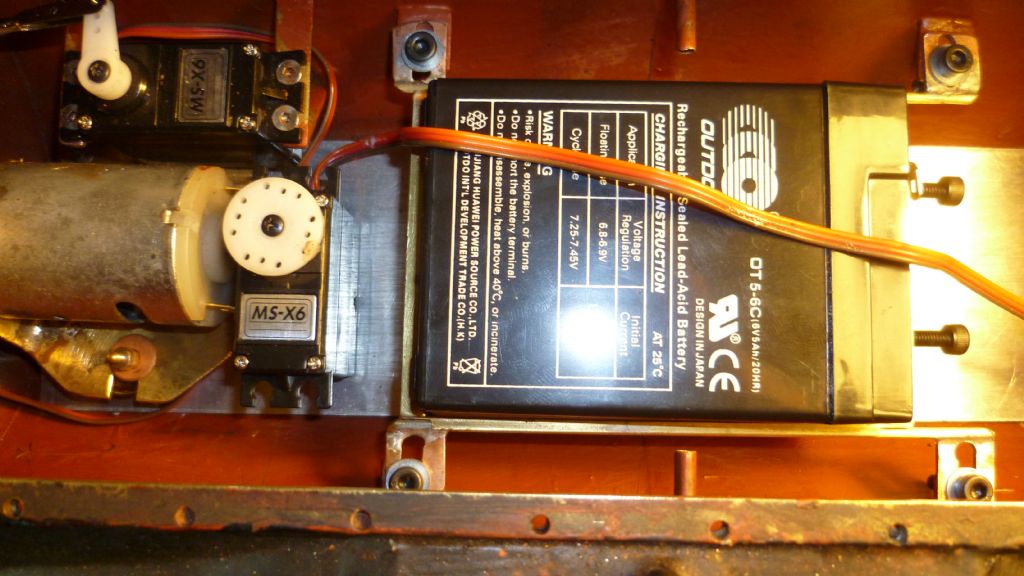

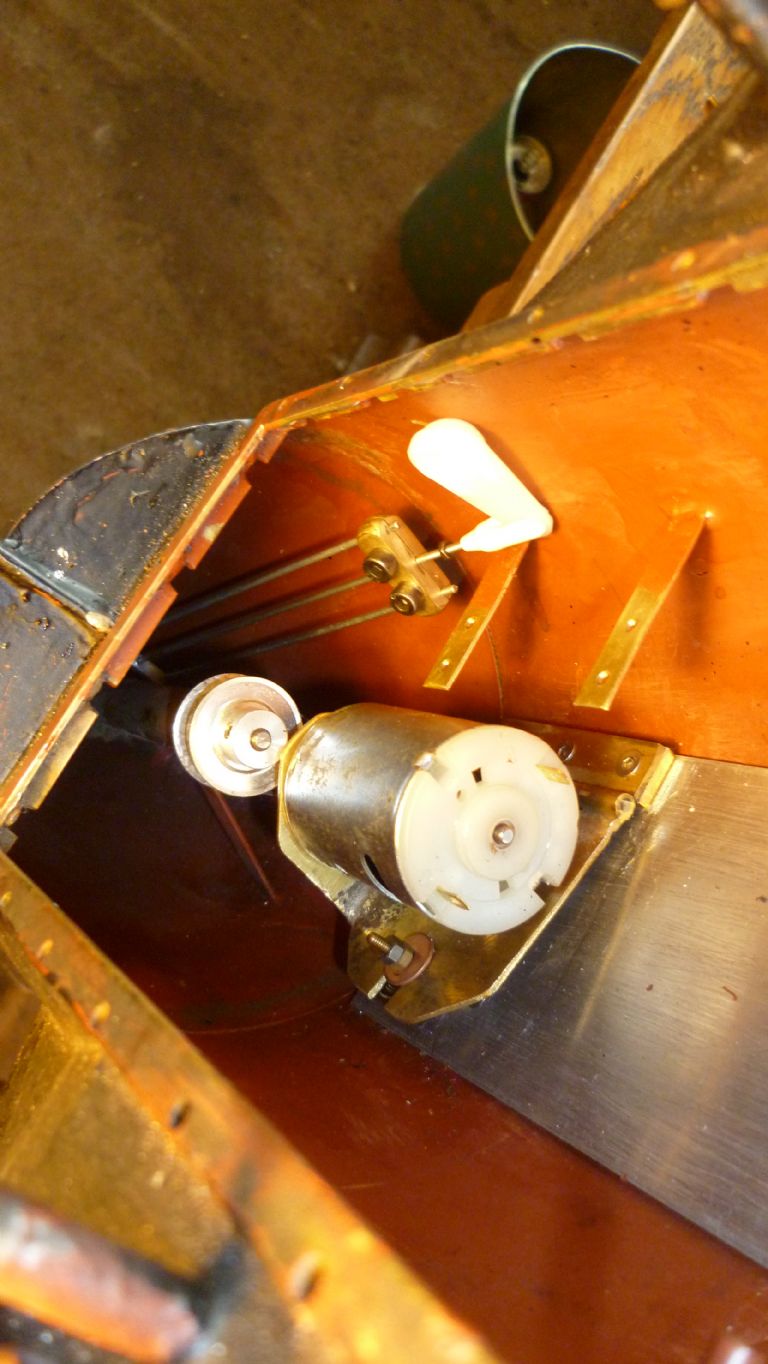

…….and the whole assembly aligned and tightened. Here's everything in place.

And Finally the waggle test.

It works, we have rudders! Rock solid and no play. Whew, Job Done!

Just to close thought I'd just chuck in some of my thoughts about Resurgams rudders. I don't think Garrett excelled himself in this area. They are completely unbalanced. Worse, the centre of pressure must be around the extreme tip of the blades. To mechanically get hold of the blades it's done at the thinnest point and they are in front of the propeller.

It will be interesting to see how they perform but I've resigned myself to living with a lot of rudder damage.

Len