Hi Everybody,

Hi Everybody,

Thank you for your kind remarks (BobA, Amy & BobW) . Such comments keep you focused when you hit one of those "and it was going so well" moments!

. Such comments keep you focused when you hit one of those "and it was going so well" moments!

Now about rust. How rusty should Resurgam be? I think she was painted by Cochrans before she was launched but there is no evidence of this in the bill of materials. The only reference I can find is on page 61 of Scanlan Murphy's book which refers to a curious incident at Hodgson's house (Cochran's shipwright) :-

"During the removal of the submarine from Mr Cochran's yard, a stranger arrived at the yard and asked for a coat, saying that my father had come into contact with the new paint on [the boat] and must have another. Just as we were getting it, my father appeared and the stranger bolted."

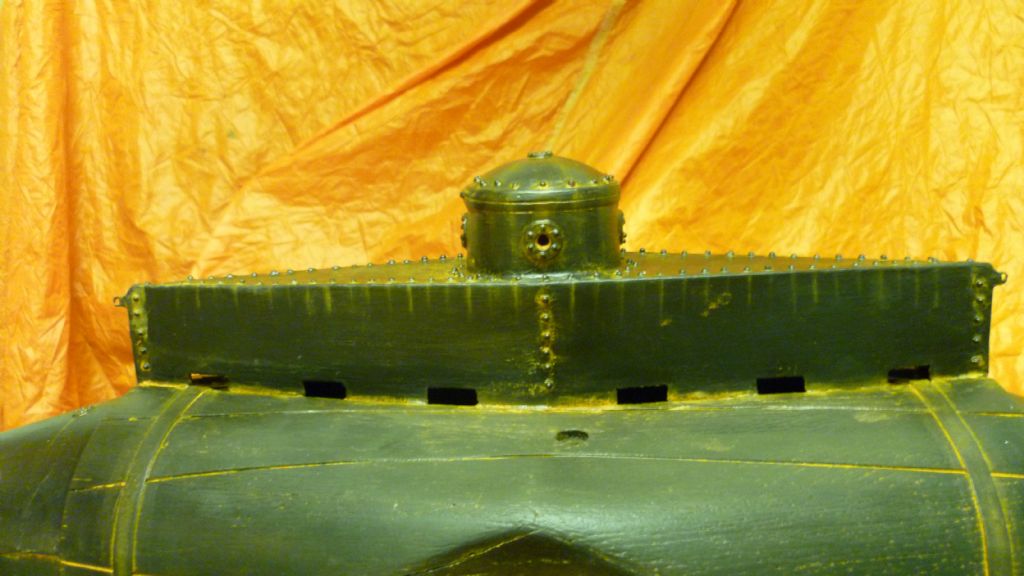

Whatever all this was about, I believe Hodgson would not have gone for a coat unless he knew Resurgam had been painted. After much pondering I've convinced myself that Resurgam was painted, and was painted black. The point of all this rambling is that I don't think Resurgam would have been that rusty when launched.

Now Resurgam had roughly a 3 month life. How much can a boat rust in 3 months? Maybe a lot above the waterline but surely not much below. However, she also spent most of her life beached in Rhyl fully exposed.

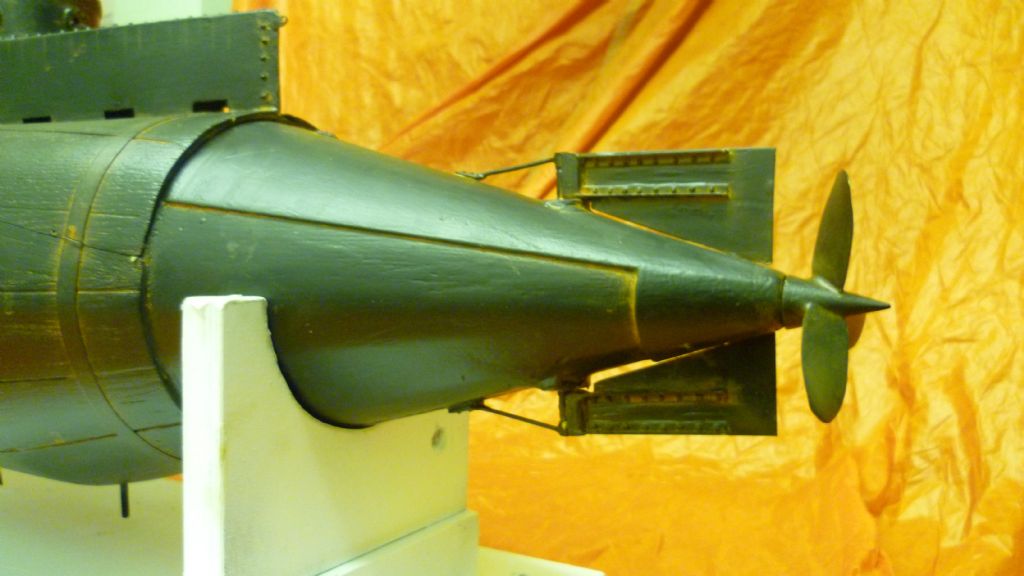

I've been churning all this about in my head for some time and finally took the plunge the other day. Mi boat will look like the day she left Rhyl. Some pictures follow (or maybe lead). Only a start above the waterline. Nothing is fixed yet so it can all be wiped off. Is it too much? Should it be more vertical? Does it look right?

BobA and BobW, I know you will read this and will really appreciate your expert comments. You do not have to be nice! If you think it is rubbish then say so! It's fun doing it and will keep getting done until it meets your approval.

Off now to find the engine.

Len