Hi Bob A,

I hate wood and I hate woodwork. It moves all over the shop and sucks up water for England. At least when I make something out of tin brass or steel it has the courtesy to stay the same shape and stay where it was put!

Cladding mi boat was a necessary evil (like going to the dentist) and it was only going to be done once! Hence the search for a decent glue as I found soldering wood not good. I wanted to use a rapid twin pack epoxy but on reading the small print they were all water 'resistant' but none of them went the distance and said waterproof and suitable for continuous immersion. That's why I used JB Weld's Marine Weld epoxy. The blurb says quite clearly that it is waterproof when cured and retains its strength above or below water. Perhaps the others do, but they don't say it and I wasn't going to take the risk. All the info is at http://WWW.jbweld.com. (Sorry, not clever enough to create a link).

The problem is that it does take 24 hours to cure and although they quote a set time of 25 minutes it's more like 6 hours (perhaps I need to turn on the central heating). Putting the strips on mi boat just took forever. I hate wood. I hate wood!

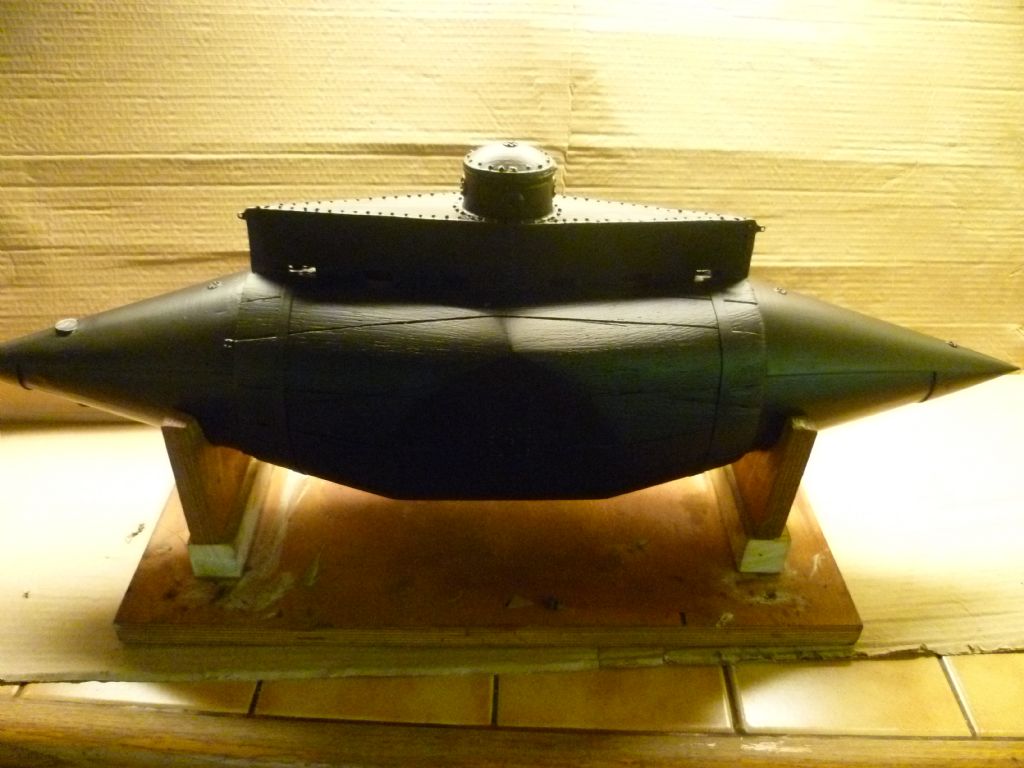

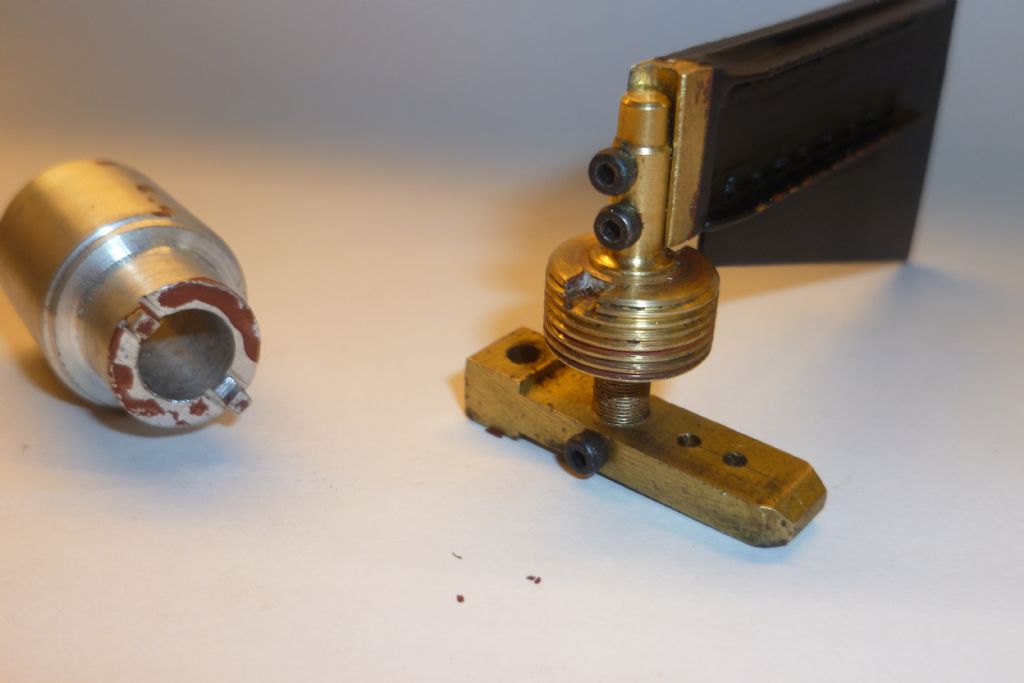

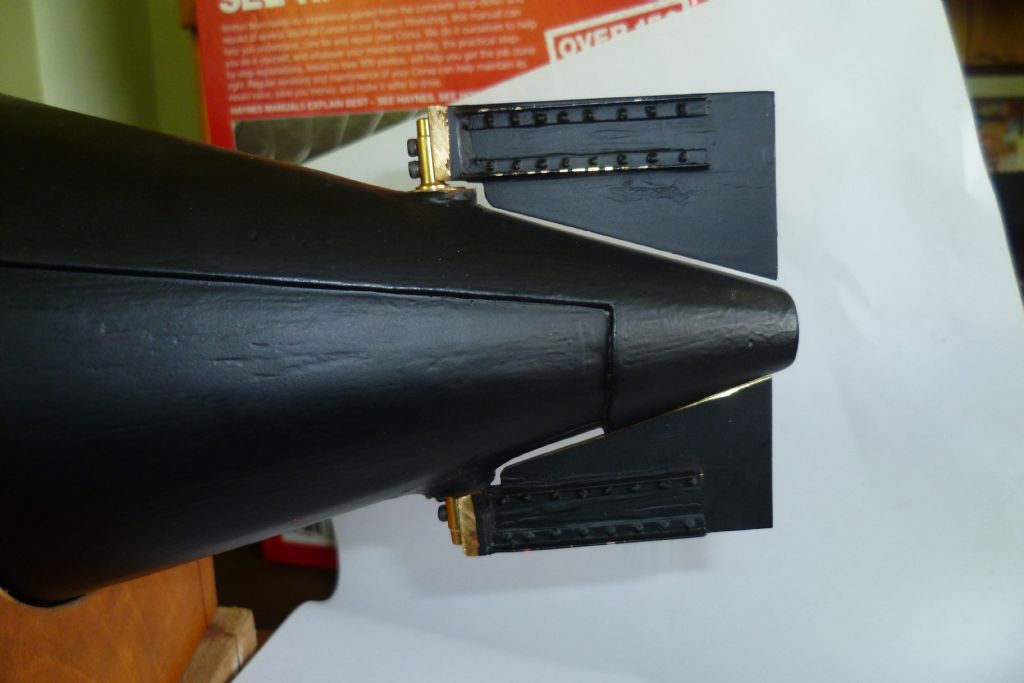

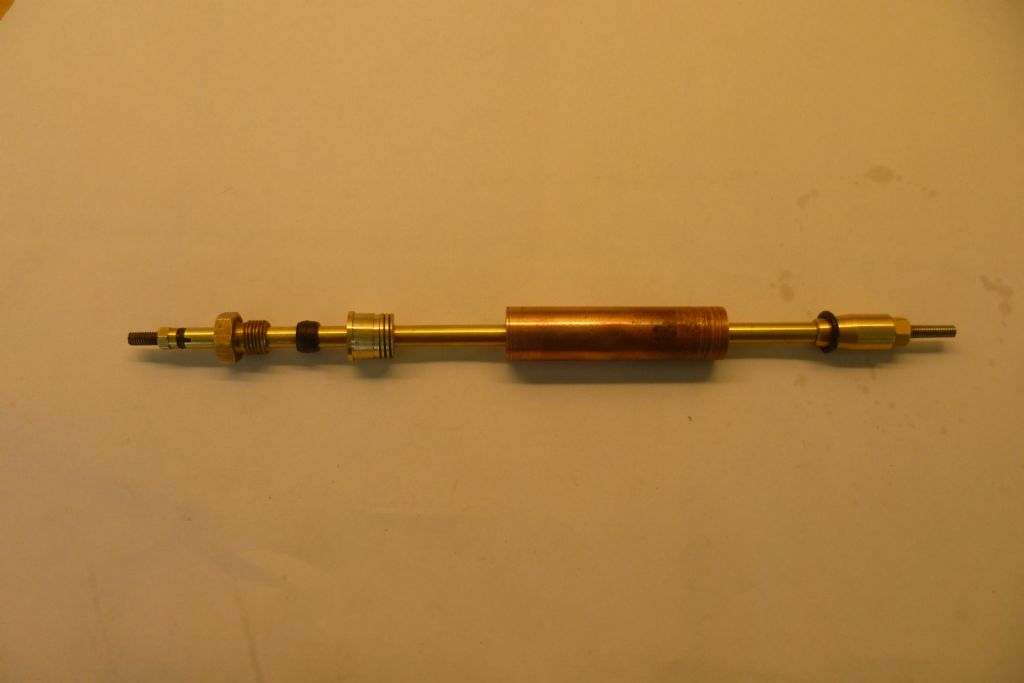

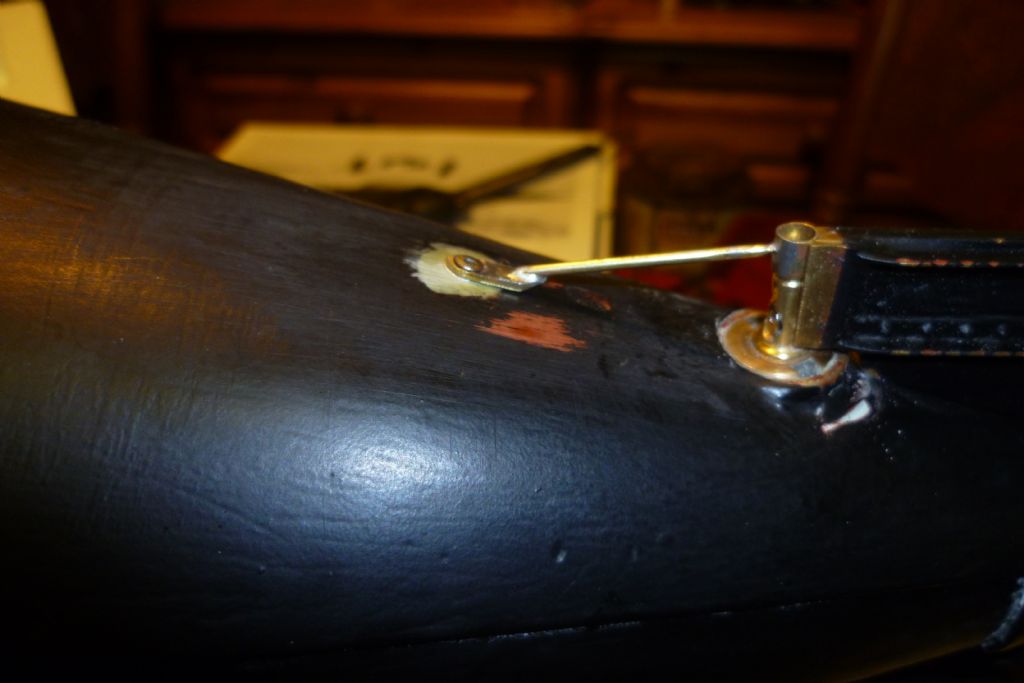

Now to the good bits, nowts going to get wet (bit of the Garrett spirit here). Under the casing is a 3.5 x 10 inch plexy glass hatch. I know it seals from the early bath trials. The bits that only turn through 45 degrees are sealed with silicon tube over the shafts and housings and the propshaft has a spring loaded grease and cotton wool seal. Job sorted. (I know I shall regret those words)!

As an aside, I have read all 66 pages of your GE thread. Just publish it as an unabridged book. Excellent!

Best Regards,

Len