It's funny how many times solutions or flashes of inspiration come to me (usually for work) when having a shower etc. but this morning was one of them.

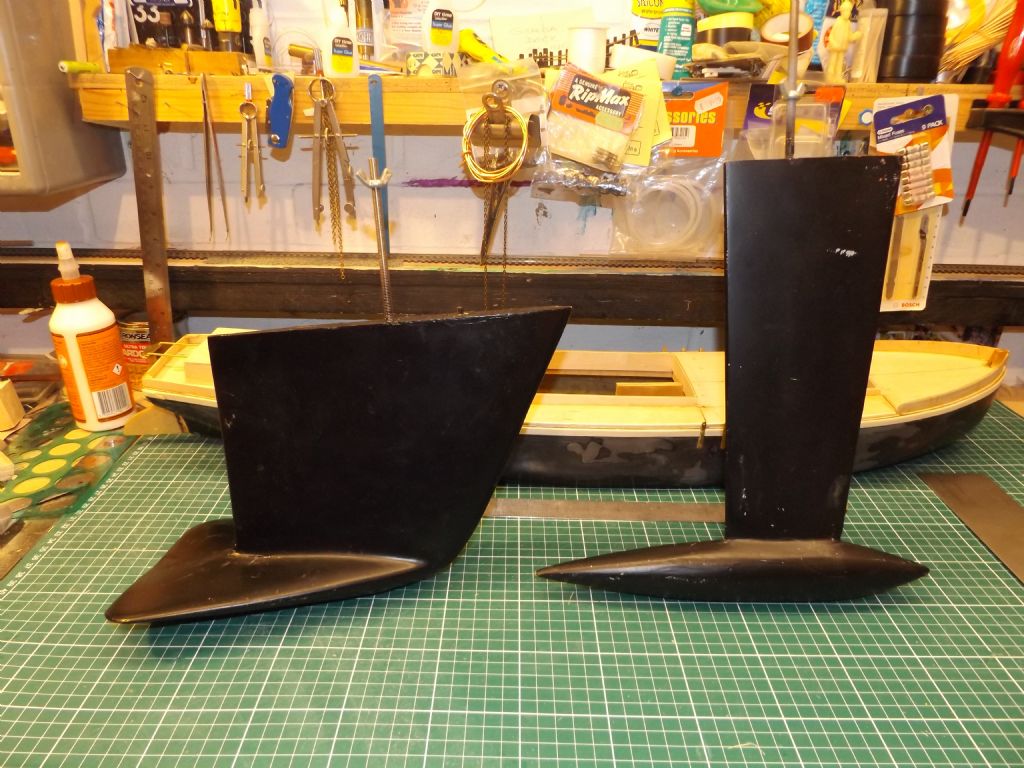

Despites its benefits the trouble with the dagger board approach for this model, it being a motor sailer, is that the dagger board assembly is going to be bang in the middle of the boat and will be just where the battery needs to go.

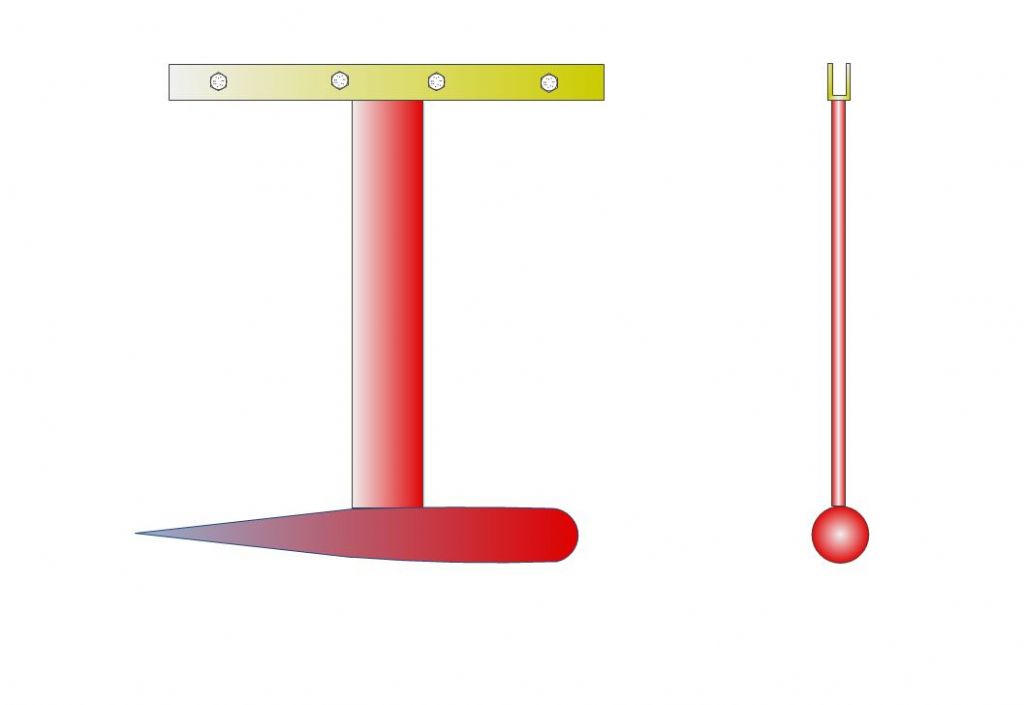

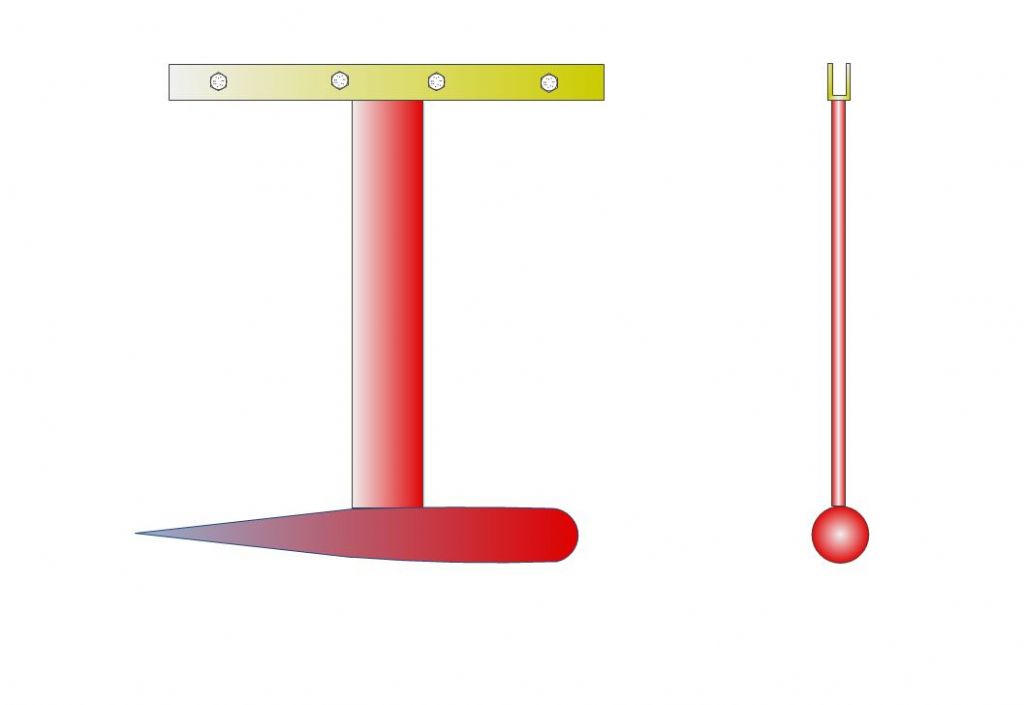

The Fisherman has a small external keel, which I could deepen a bit, and I could bolt the bulb keel to that. I'm going to use mahogany for the keel (even though its painted) to work with something other than ply and for additional strength some brass strip could be fixed either side.

A brass channel could then be fixed to the top of the fin and then bolted to the boats keel. The sail area isn't that great and I shall only use it occasionally in light winds so the forces between the hull and keel won't be that great and will be transmitted to the hull's keel which will be the strongest part of the boat.

One advantage of this approach of course it that the keel can be moved forwards and backwards easily to find the optimum position.

Probably not a new idea for seasoned modellers but it is for me!

Chris

Edited By Chris Fellows on 09/09/2018 11:19:11

Chris Fellows.

Chris Fellows.