My take on this, and, as usual there will be as many preferences are there are members, is to always make any removeable part in place on the model to guarantee a nice close fit.

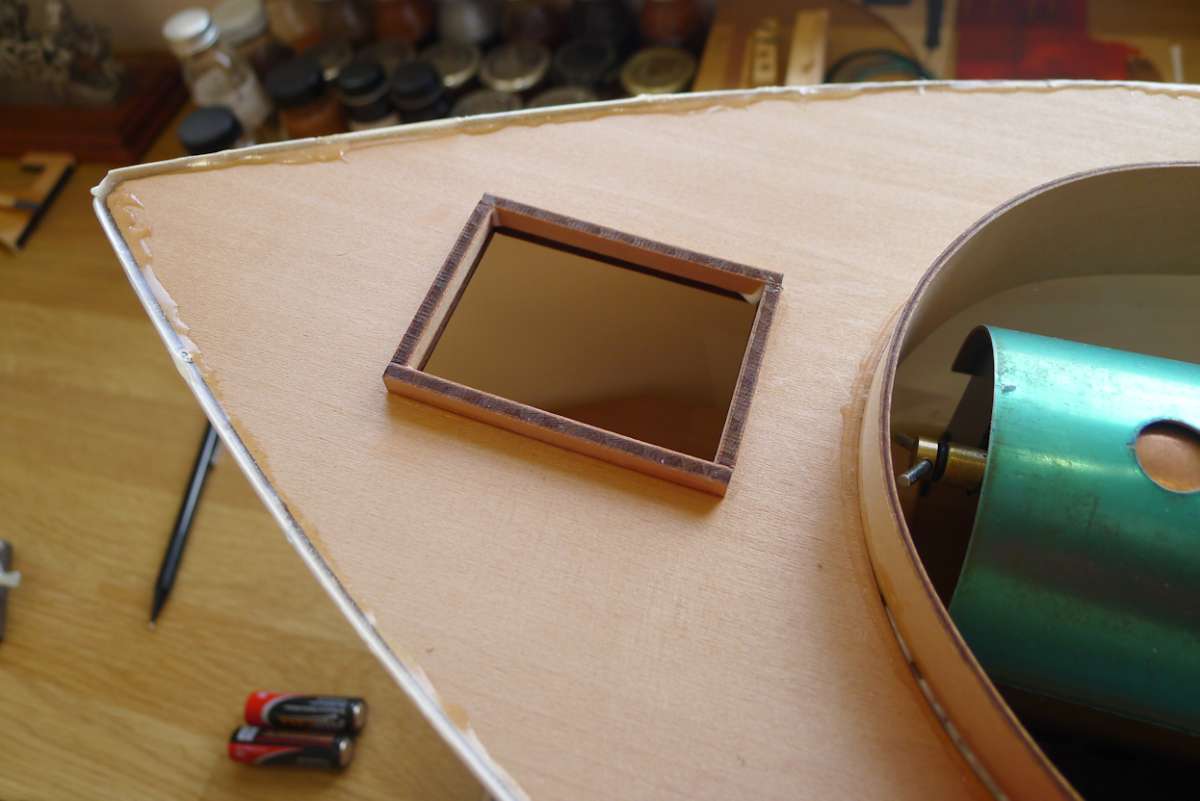

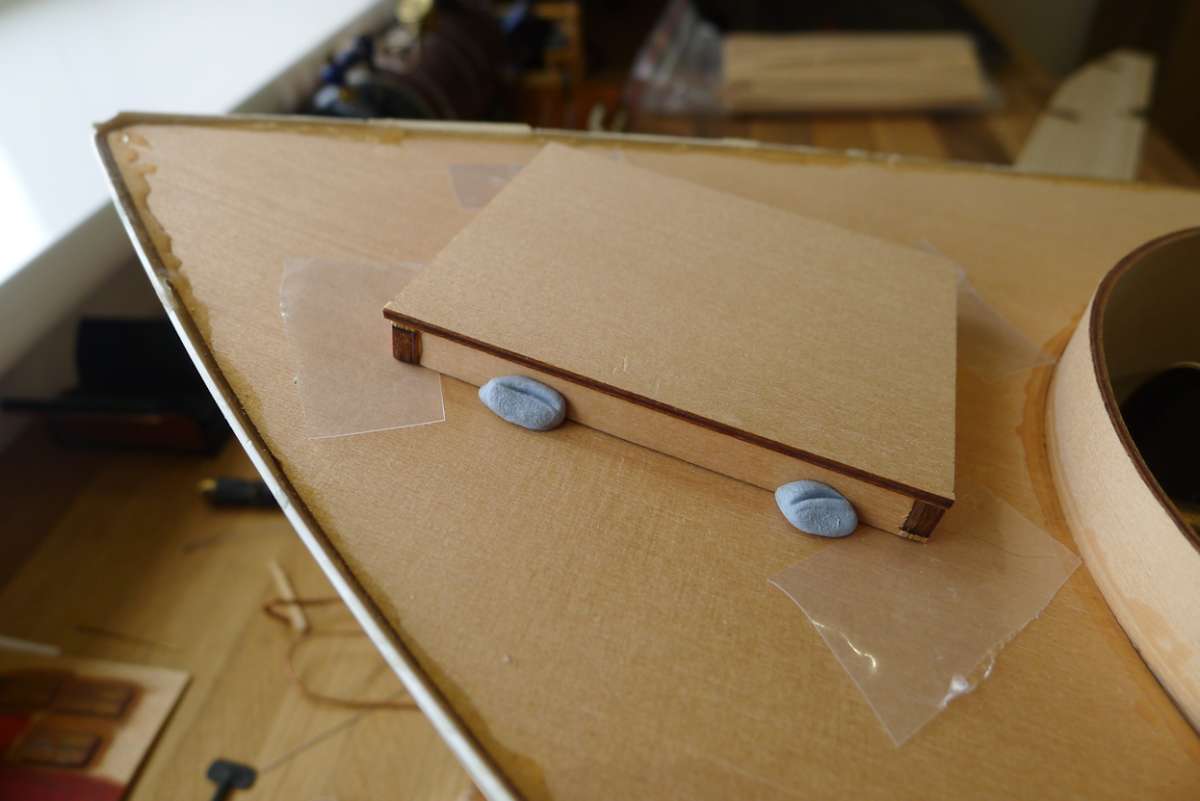

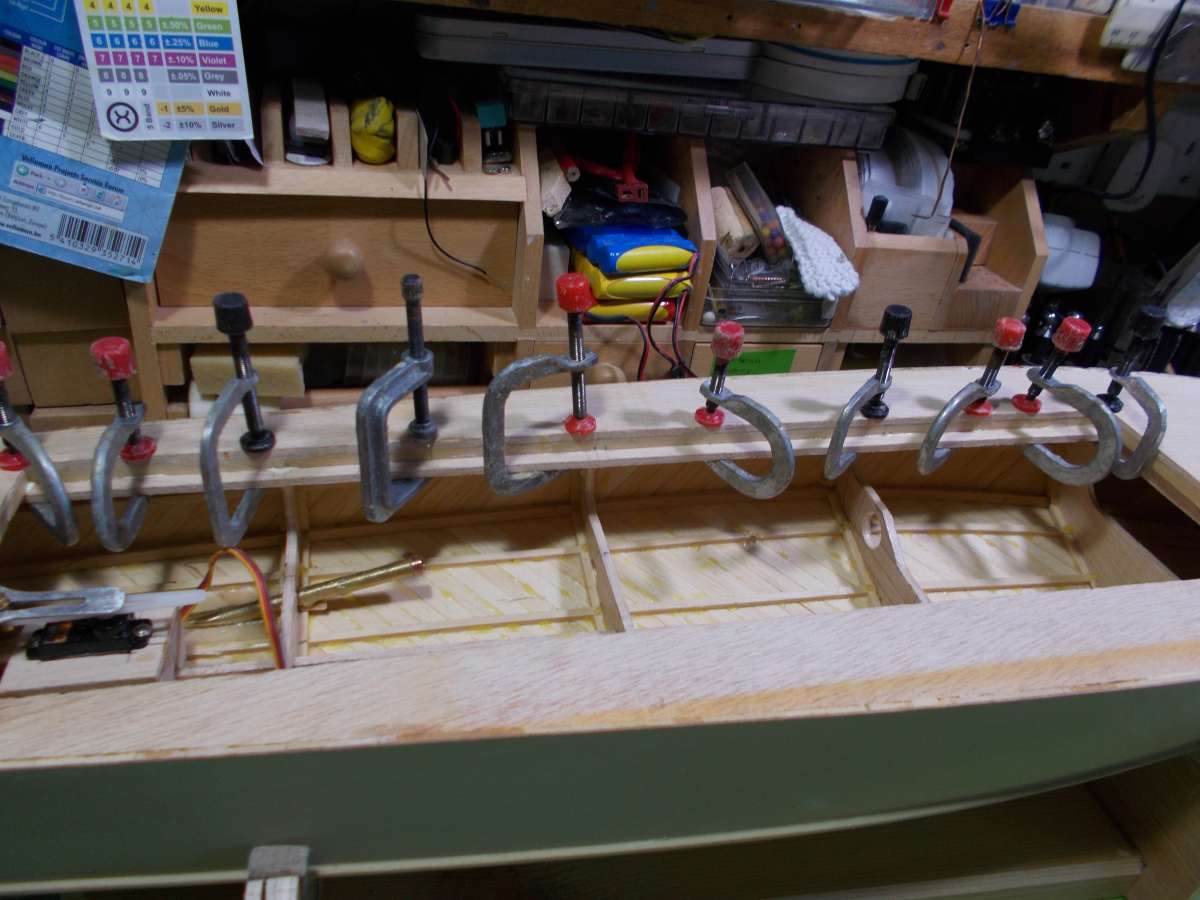

The way I do it is to cut the hole and fit the coaming, as you have done. Then build the sides of the hatch in place around the coamings, which could be either a softwood frame or vertical sidings, as you prefer. Hold in place with blobs of BluTac while the glue sets so you have a frame that perfectly fits snugly around the coaming. Then you can build up from there, again with everything still in place. Finally glue the cover onto the sides while it remains on the model, with a slight overlap. You can then remove it and trim it so the cover fits perfectly. and add stiffeners inside to beef everything up.

Some modellers try to use the removed piece of ply as the hatch cover but I never bother. It will never be big enough to give you enough to play with for that perfect finish.

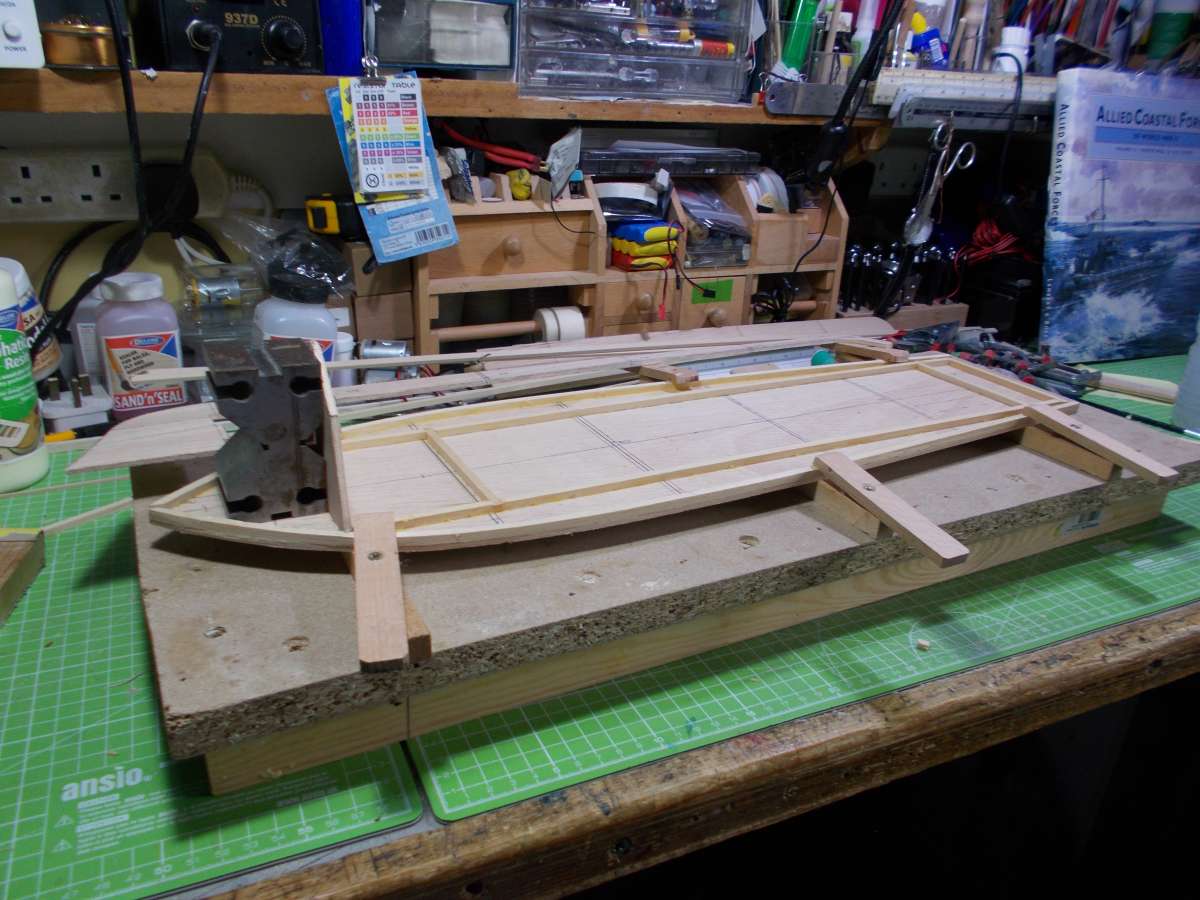

I build hatch covers this way and even wooden superstructure components in the same way to always give me a nice snug fit.

cheddar24man.