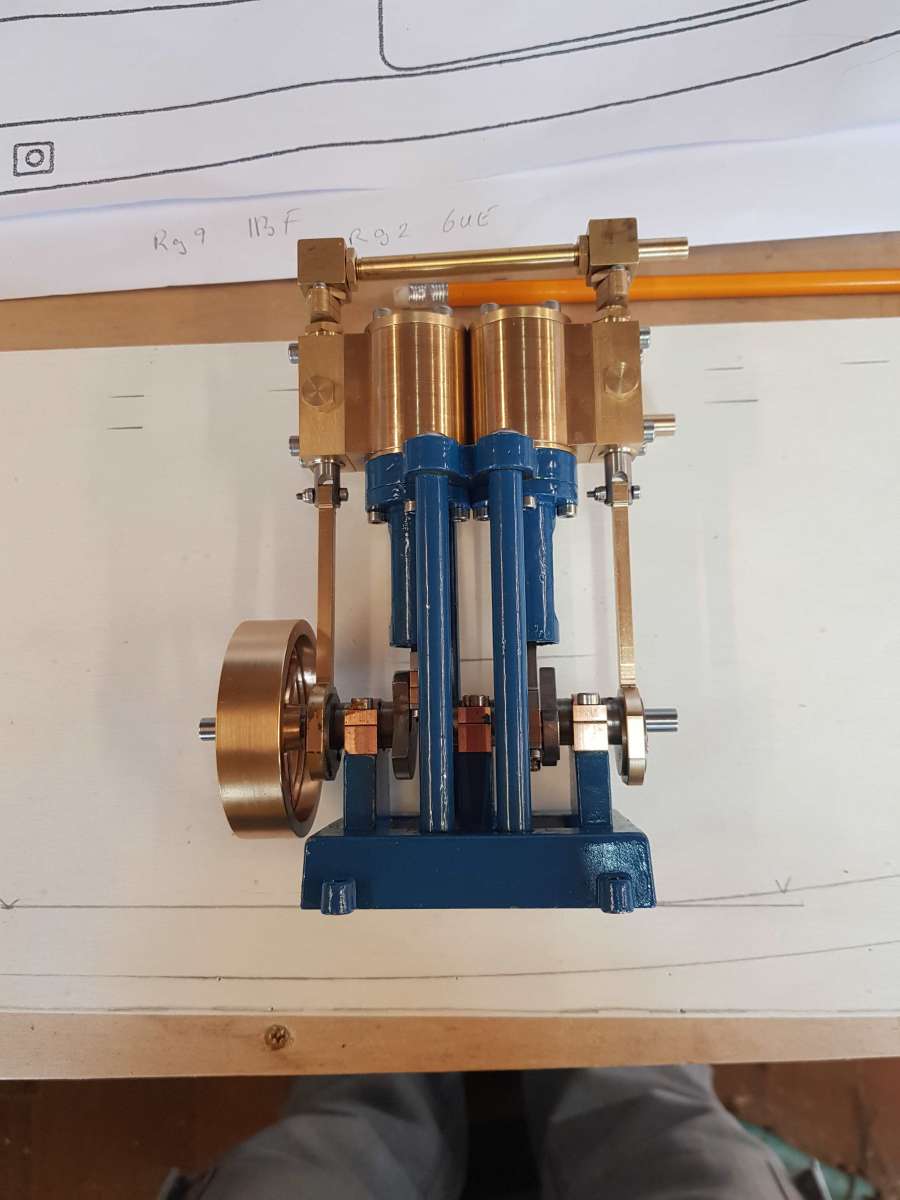

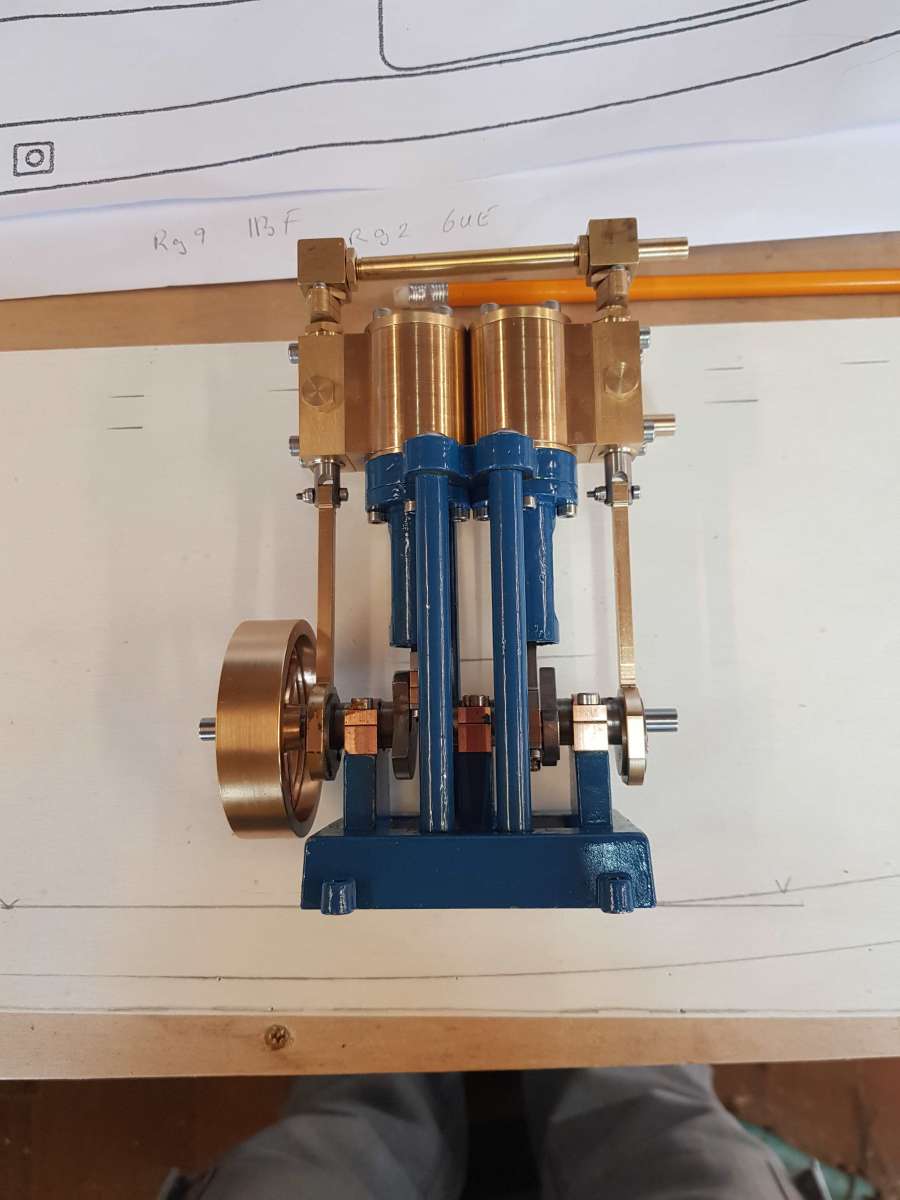

The build, the start was to see if the engine would look reasonable in when placed on the enlarged plans, this can be see here first image.

With the engine sitting on the keel it will be just proud of the deck line.

With this confirmed, I moved onto the build. starting with the keel and bulkheads taken from the plan realising the building board was not going to be big enough, new building board made and starting to work out how to get the planking on but still have the keel etc secured to building board by blocks image 3.

With the keel set and all bulkhead in position, glued and all chamfering carried out to accept planking i removed the complete keel/bulkhead from the board to ensure it would release after planking. The Tulip timber planks were reduced to enable the 3 inch circular saw to cut up for planking. These were glued using titebond 3 with blocks of wood and screwed to base board to hold in position while drying. Some of the planks were tapered to the ends to allow the same amount of plank from gunnel to keel. More to follow

Terry

Terence Gregory.