The rails are 5-bar made from 38swg tinned copper wire. The simulated teak capping on top is also made from tinned copper wire beaten flat on a shiny piece of steel. The ladders are also made from tinned copper wire, and the rungs are all soldered in. The ladder handrails are 38 swg tinned copper, each side consisting of four lengths. The cowl ventilators are again made from two thicknesses of tinned copper wire. Here are the ladders. All this sort of thing is not difficult at all, with special methods. Sadly, very few model shipbuilders will try it, declaring that the could never possibly do it, without even trying. I have ceased to even take them along to the local model shipwright society that meets every month, because they rarely attract more than a casual glance. But, on the other hand, collectors all over the world are falling over themselves to get their hands on them, and because of this, I had to stop taking private commissions some years ago because it was becoming like a millstone round my neck. I often hear it said that the model builder is too busy, and does not have sufficent time to scratchbuild, but when I ask them how long it takes to build a kit, the answer is usually in months, or even years

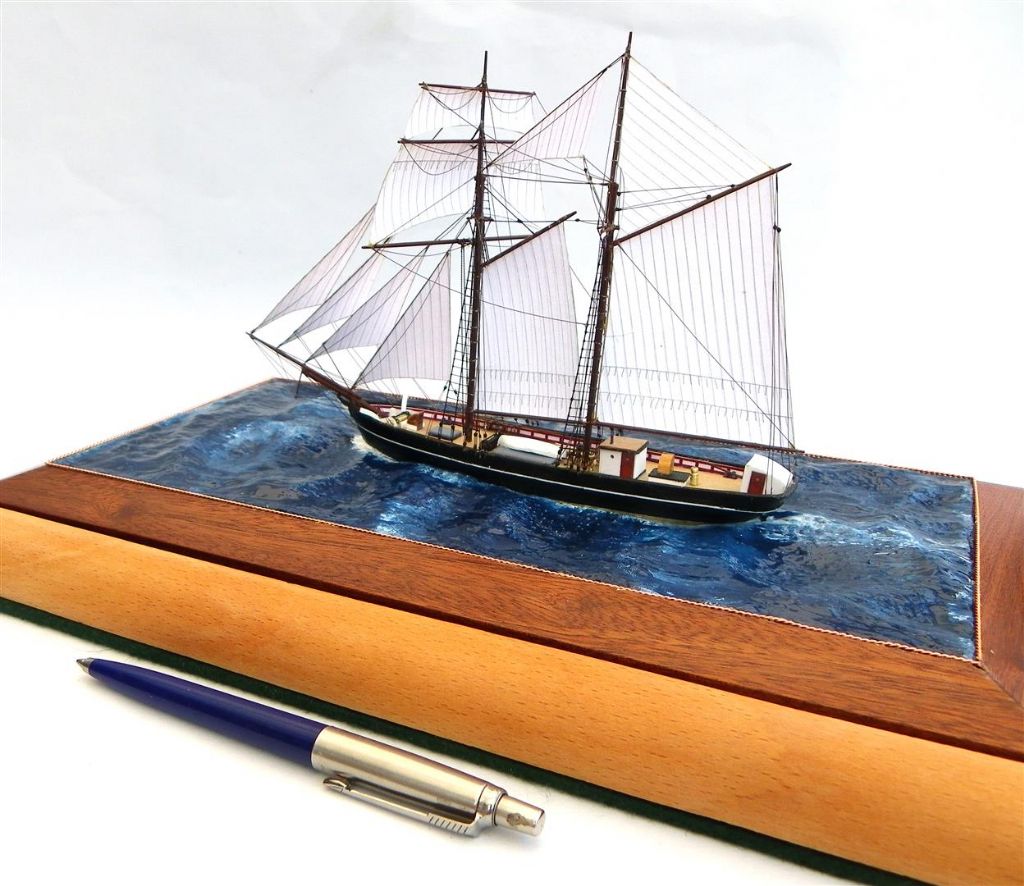

The rails are 5-bar made from 38swg tinned copper wire. The simulated teak capping on top is also made from tinned copper wire beaten flat on a shiny piece of steel. The ladders are also made from tinned copper wire, and the rungs are all soldered in. The ladder handrails are 38 swg tinned copper, each side consisting of four lengths. The cowl ventilators are again made from two thicknesses of tinned copper wire. Here are the ladders. All this sort of thing is not difficult at all, with special methods. Sadly, very few model shipbuilders will try it, declaring that the could never possibly do it, without even trying. I have ceased to even take them along to the local model shipwright society that meets every month, because they rarely attract more than a casual glance. But, on the other hand, collectors all over the world are falling over themselves to get their hands on them, and because of this, I had to stop taking private commissions some years ago because it was becoming like a millstone round my neck. I often hear it said that the model builder is too busy, and does not have sufficent time to scratchbuild, but when I ask them how long it takes to build a kit, the answer is usually in months, or even years with hundreds, or thousands of hours work! My miniatures rarely go over 50 or 60 hours! (All timed on a stopwatch) The collier brig Sicily, shown above, took 25 hours, spread over 13 days, and that included making the display case and carrying case. Building costs – virtually nothing, as it was built from bits and pieces left over from larger ones.

with hundreds, or thousands of hours work! My miniatures rarely go over 50 or 60 hours! (All timed on a stopwatch) The collier brig Sicily, shown above, took 25 hours, spread over 13 days, and that included making the display case and carrying case. Building costs – virtually nothing, as it was built from bits and pieces left over from larger ones. .

.

Bob

PS. The hull length of the brig is about 3 1/2 inches!

Edited By Bob Wilson on 08/05/2018 06:37:30

Edited By Bob Wilson on 08/05/2018 06:40:37

Edited By Bob Wilson on 08/05/2018 06:42:14

Edited By Bob Wilson on 08/05/2018 06:43:21