60cm is on the small side for a radio control sailboat, so it will need all the help it can get.

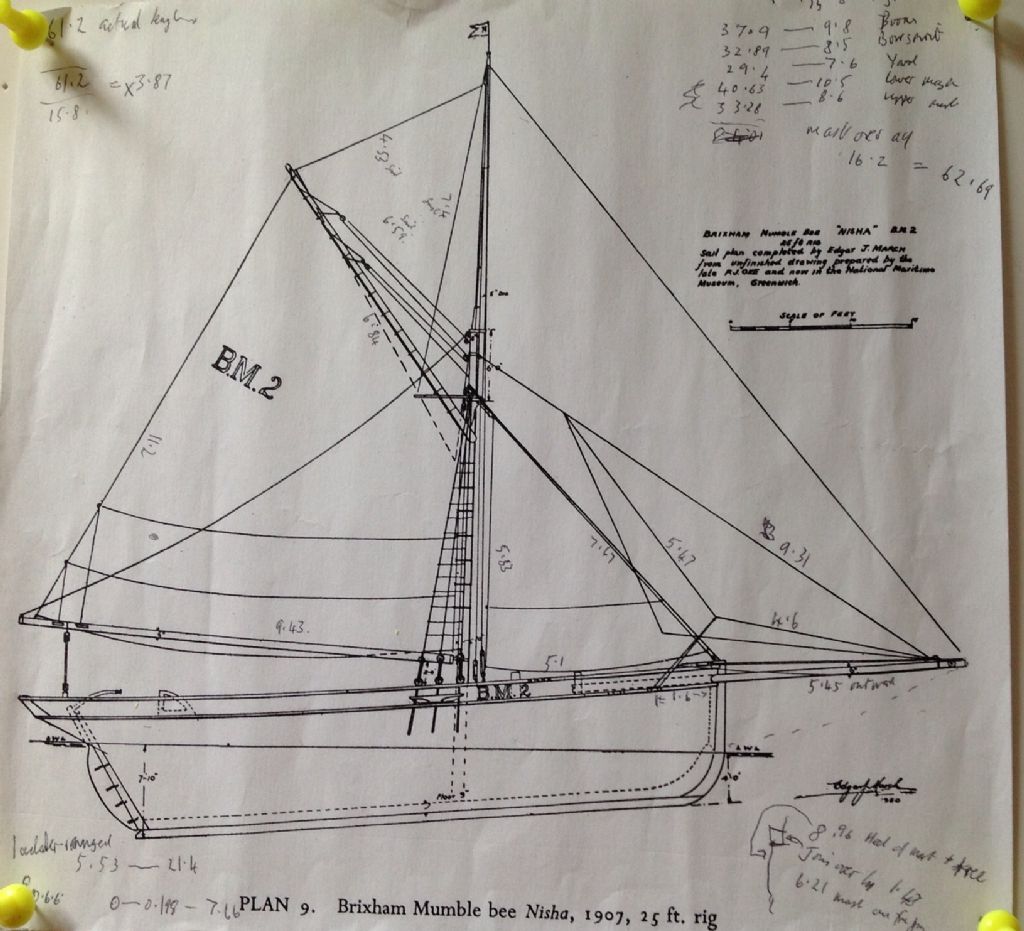

The "racing fin and torpedo shape bulb" is probably simplest. It will need a threaded metal rod to supply the rigidity (and if it pokes out the bottom of the fin, is handy for mounting the weight), and will need to go up to deck level via a tube. Threaded so you can get a nut on the top. This arrangement spreads the load beteen keel and deck beams, more or less eliminating the twisting forces. About 6" -9" of fin with the bulb on the end should work, try for about 5-10% of the sail area so the fin can help with reducing leeway. Positioning the fin – it needs to be just astern of the line of the center of effort of the sailplan, as it determines the center of lateral resistance ad whether or not it will ever steer straight. The fore and aft position of the torpedo on the end of the fin determines the center of gravity, and thus the static trim in water.

A friend, many years ago, built a 3 foot version. Looked great, sailed very fast, was unable to noticeably steer unless he used his auxiliary power, so a rudder with plenty of authority is good. His was big enough to use internal ballast, as was another boat (Bristol Channel pilot cutter about 4 feet long), whose owner didn't reckon that it had been a good days sailing unless he managed to get water into the on deck lifeboat.