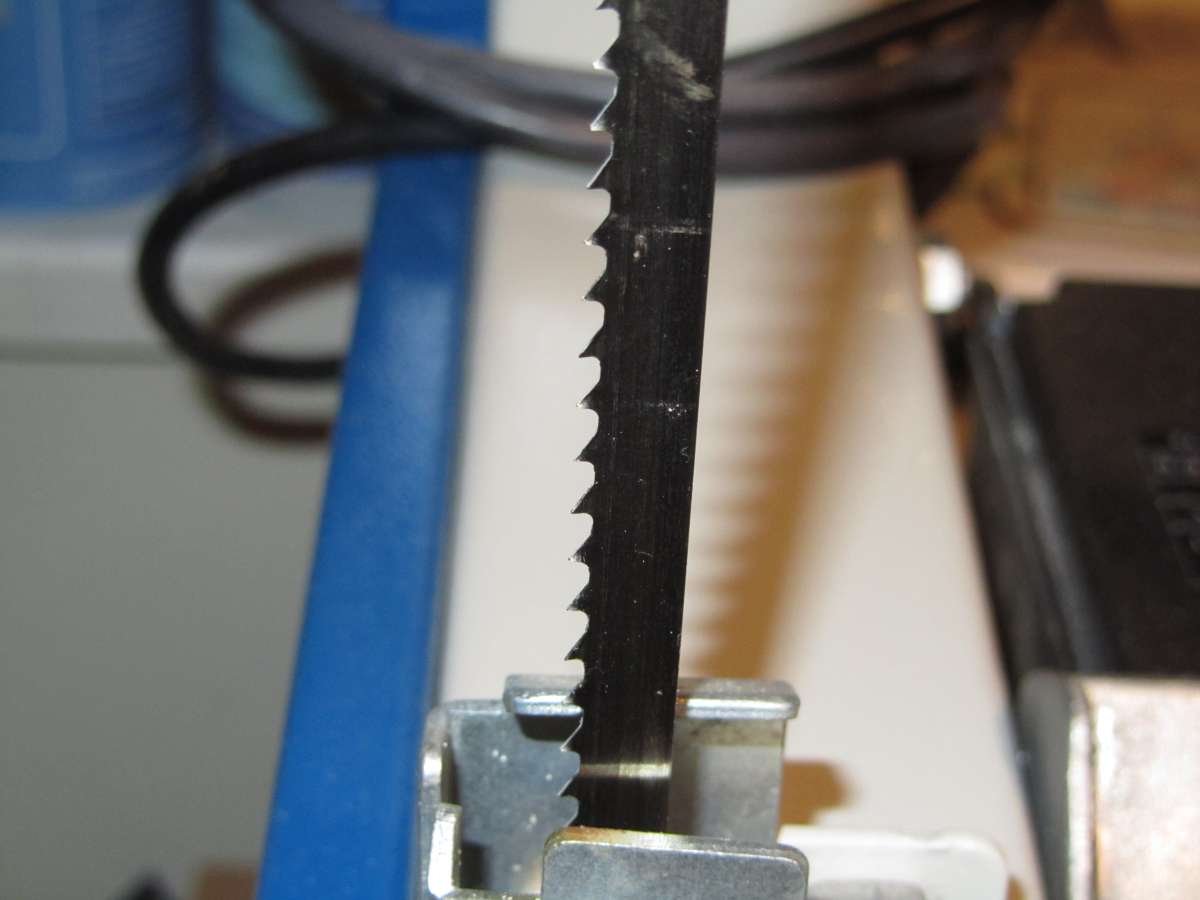

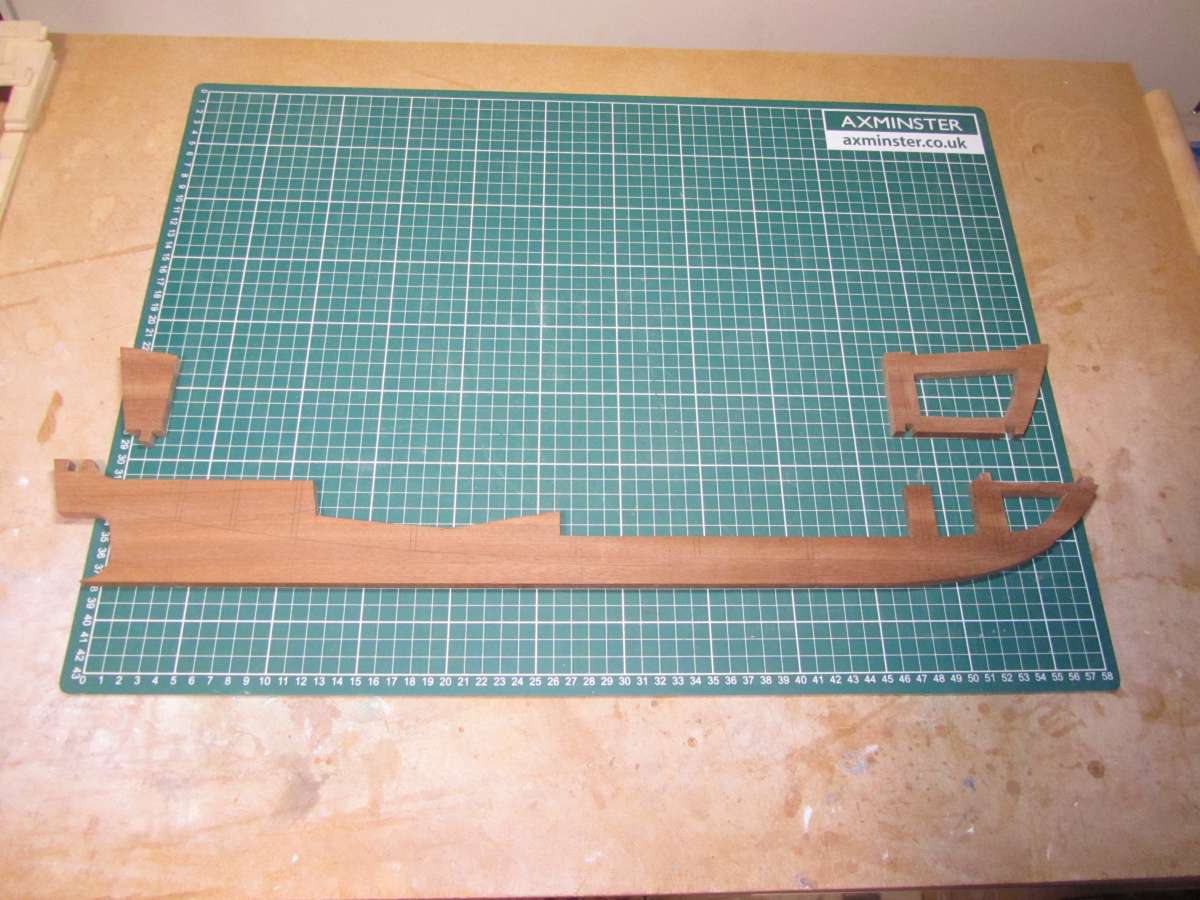

Chris, I have an Axminster band saw and have, what looks like, the same blade fitted. I thought exactly as you did that it looks a little vicious and so bought a finer blade.

However! I initially bought the saw because I wanted to cut a resin building up to fit on the model railway into the backscene. I thought I’d give it a go with the original blade and was amazed at the beautifully clean and neat cut I got through resin. There was no shattering at the cut and the cut was so fine as to even go through the detail of the guttering downpipe without breaking it. Consequently I’ve never bothered fitting the spare blade.

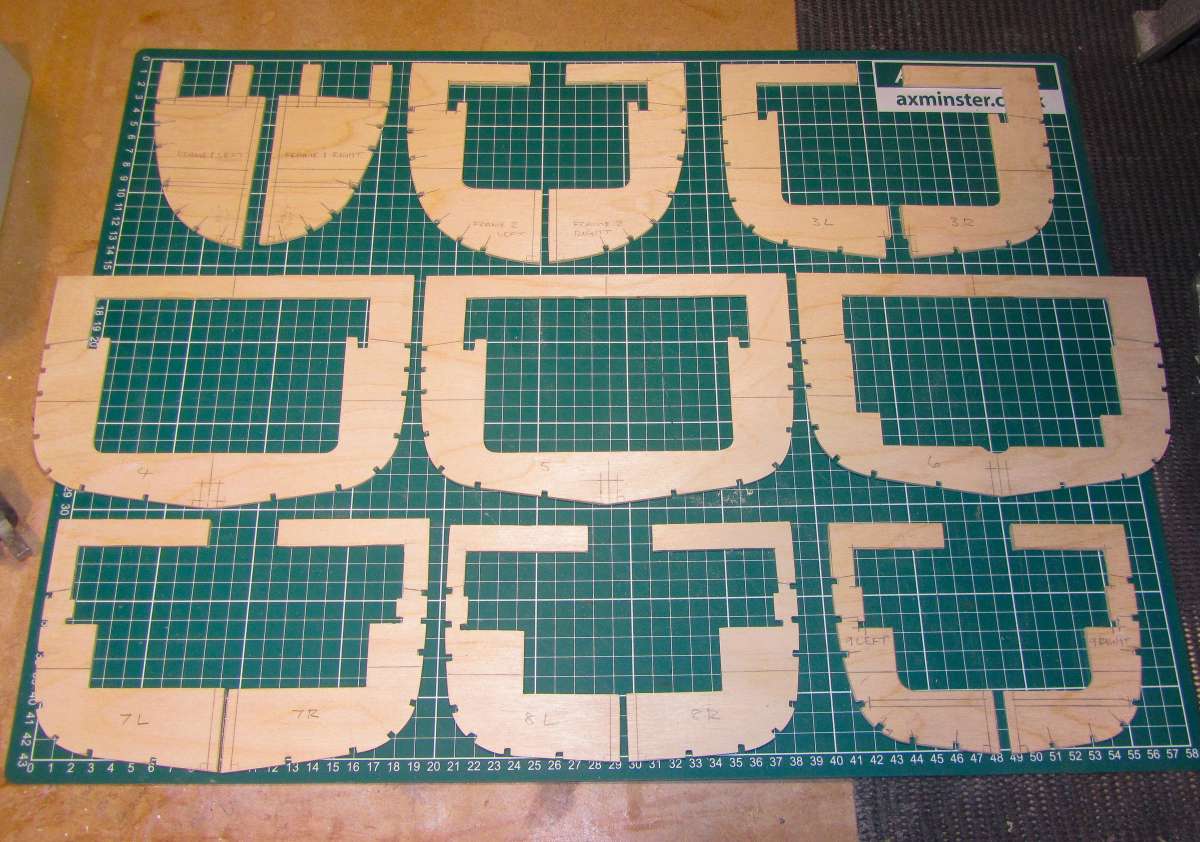

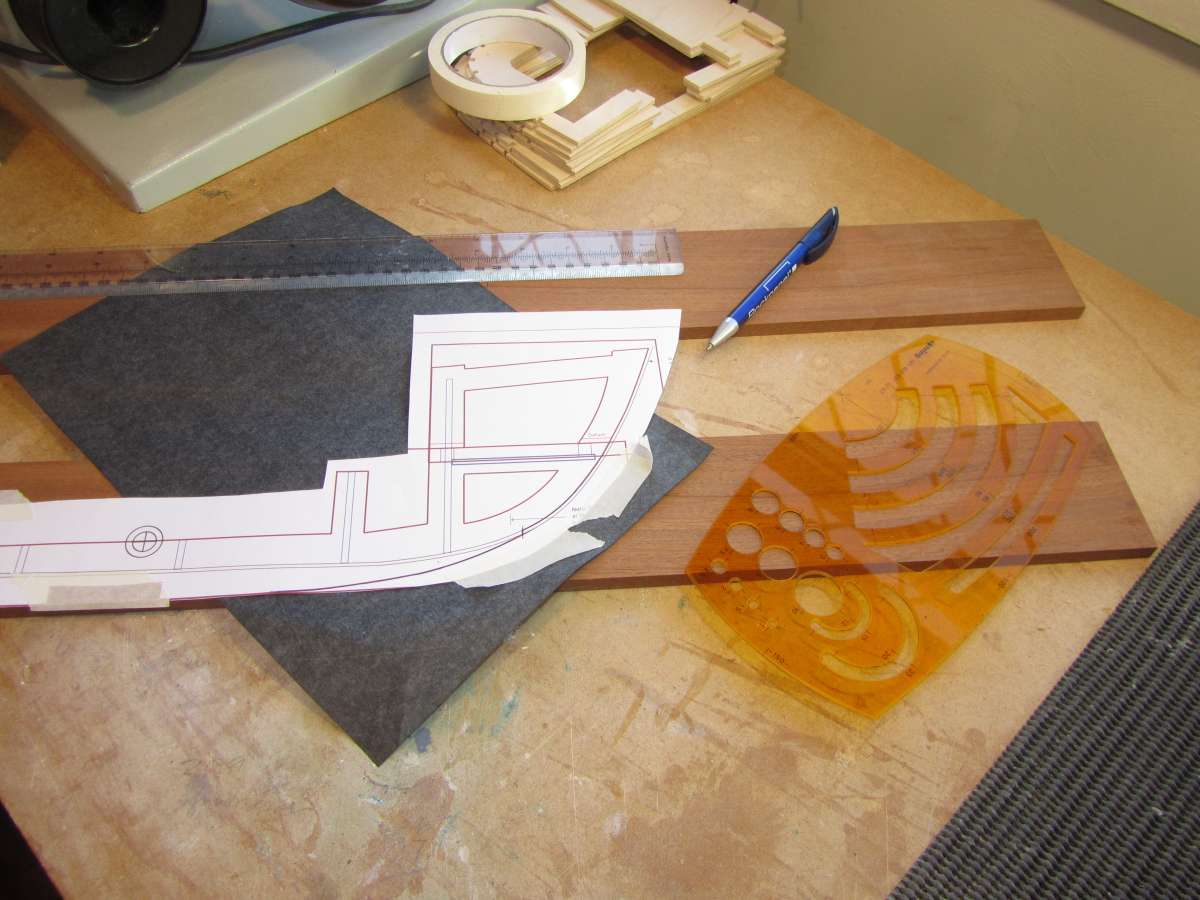

One consideration to take into account however is the radius of curvature of the cuts you intend making. If they are a tight radius the original blade is a little bit wide so you might have to consider a narrower blade. I would try a couple of cuts in scrap material and see if you can comfortably get the radius you need. I don’t know if minimum radii are quoted anywhere but it’s worth looking. Axminster have an excellent website with links to some superb YouTube videos of information and setting up and they are incredibly helpful on the phone so they might also guide you as regards minimum radii for specific blades.

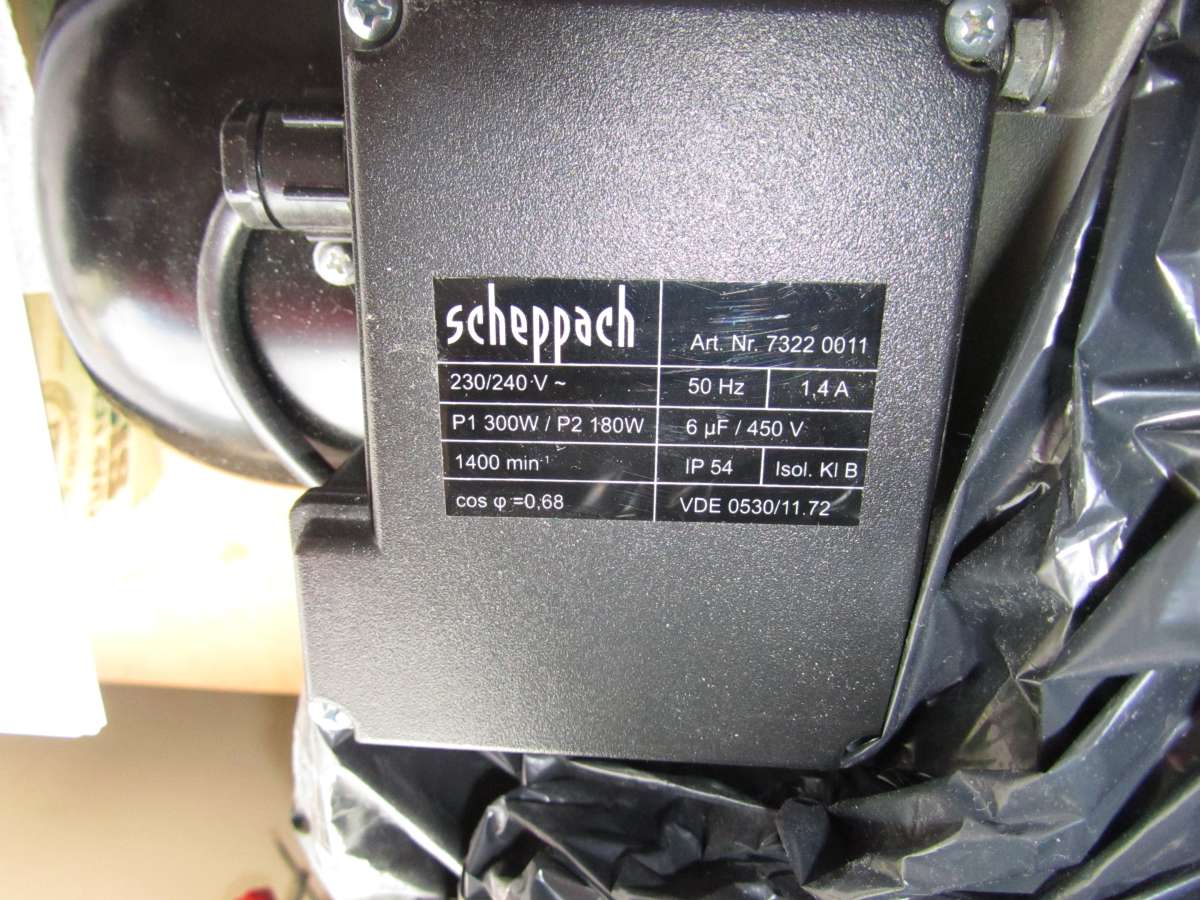

I have to say, I don’t know the make of yours, but that is a hell of a size motor for a hobby band saw. Treat that thing with huge respect!

Another thing worth considering, if you are going to use the saw in an environment where the dust might become a pain then seriously consider connecting a vacuum up to the outlet. It makes a huge difference. I have one connected up that has an outlet socket built in and so automatically cuts in when the saw is started.

Richard Simpson.

Richard Simpson.