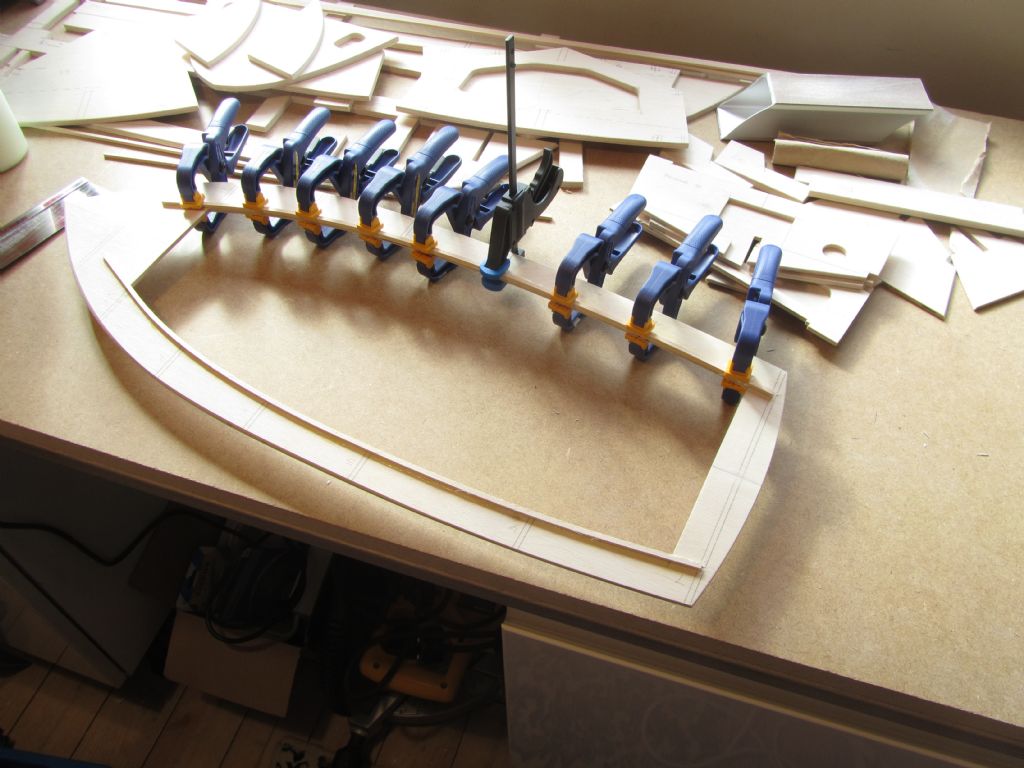

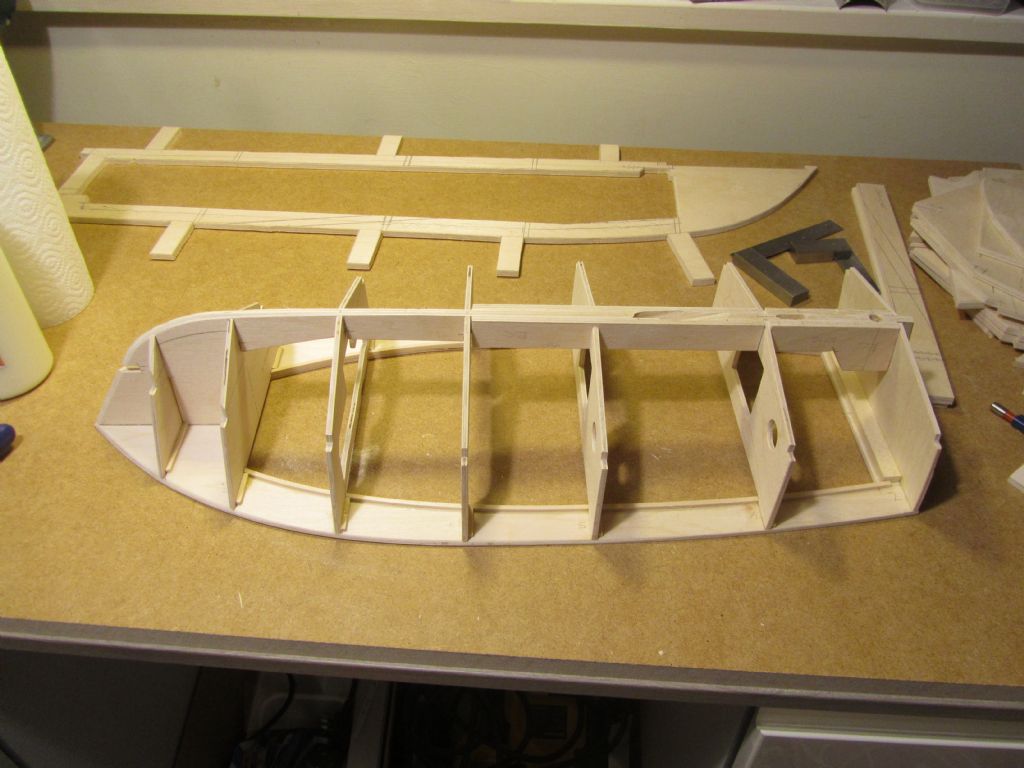

Took the clamps off yesterday and was a little peeved to find that the skin had moved whilst clamping. Only by a small amount, about 1.5mm, but if I'd noticed it I would have repositioned it. No real problem as a bit of filler will sort it, but annoying.

Also, where the skin curves towards the bow, it had sprung the stringer out of the second frame. Serves me right for not steaming it. But as it didn't take much force to bend it I thought it would be OK. Another lesson learnt! Again, it's not much but I know it's there. As before, not much of a problem to remedy.

I then did the other bottom skin but couldn't get it to sit tight along the keel, even using some weights, as the birch ply is quite stiff. Had to resort to using some small screws. I steamed it this time which made it much easier to fit.

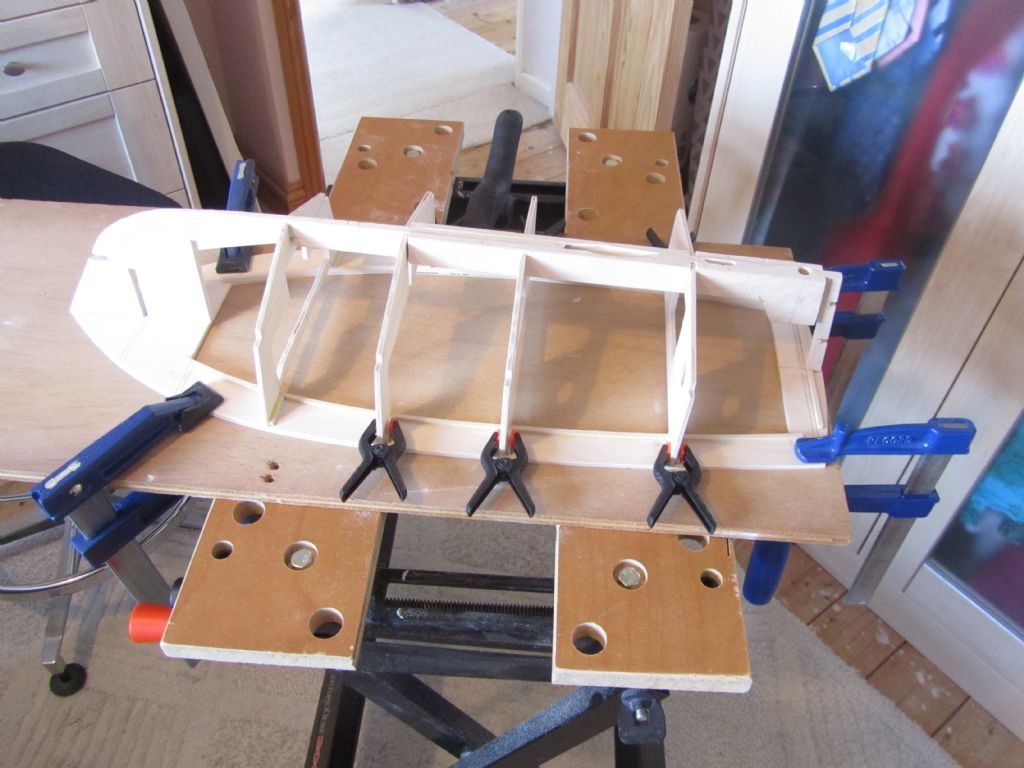

Then tonight I fitted the first skin on the Huntsman 28. Actually found this a little easier, being a bigger hull I suppose. Not all plain sailing though as again the skin slipped when clamping despite putting some pins in first – but at least I was looking out for it this time. So took off all the clamps, pulled it off, reglued it and clamped it again. Then blow me it slipped again. I thought modelling was supposed to be relaxing, I was started to get a little stressed! But third time lucky I had it beat!

Chris Fellows.

Chris Fellows.

what adhesive are you using?

what adhesive are you using?