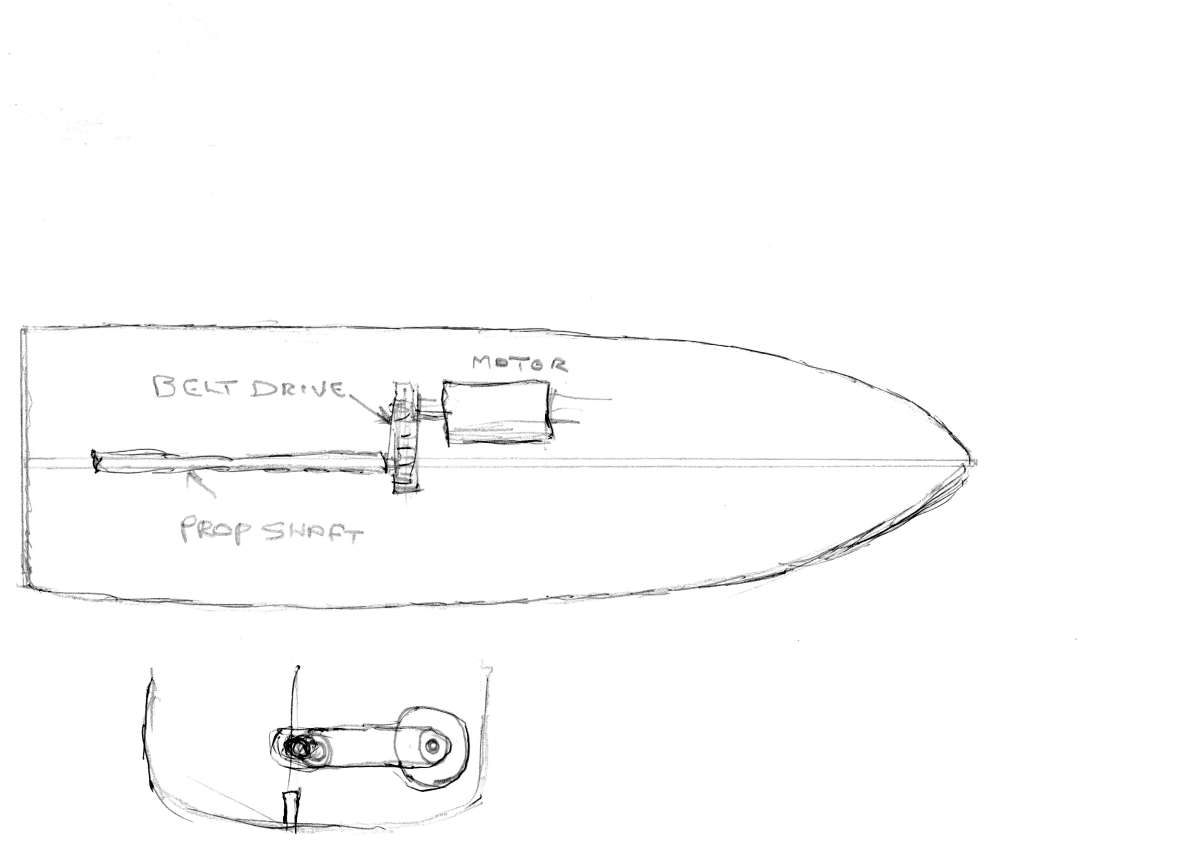

I think the main value of using two is the fact that they can allow for parallel but displaced misalignment while a single one can only allow for angular misalignment.

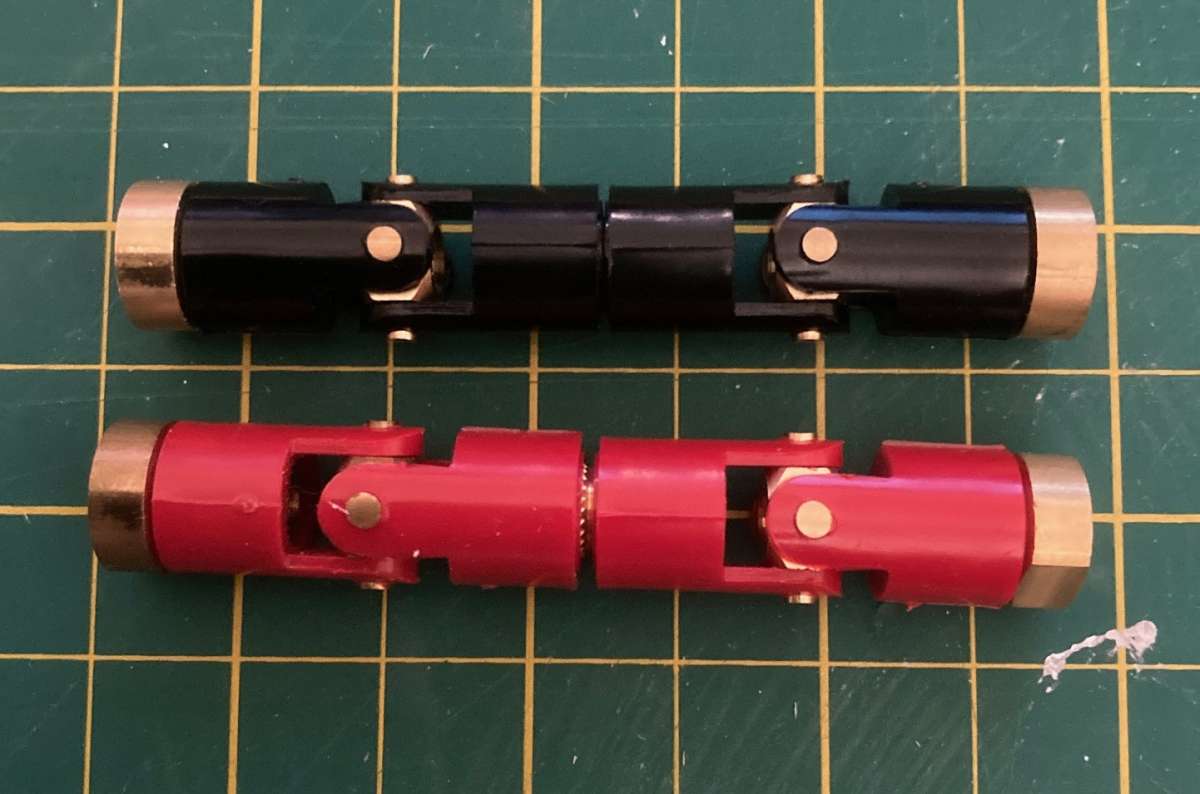

Over the years though I have become more and more disillusioned with the Huco type coupling. I have frequently found them to be poorly manufactured and anything between sloppy and very tight on the splines and frequently out of balance. I have also noticed they can be quite a tight fit at the cross piece bearings, which relates to power losses. There are metal alternatives, which seem to be of a much better quality but, not surprisingly, much more expensive.

What I do think we sometimes forget is the fact that the strength of the Huco coupling monumentally outweighs the power that is being transmitted. Frequently, especially in scale models, the power can be very easily transmitted with a short length of silicone tubing pushed onto the brass splines. This will accommodate any type of misalignment, takes no power from the transmission and runs beautifully quiet. UV joints obviously have their uses with higher power outputs but I still have serious reservations with the plastic Huco type.

I once saw an article that explained precisely how the issues Len refers to happen in a UV joint. Very interesting and helps to explain some of the challenges with them.

Interestingly only last weekend I witnesses a steam tug at our annual steam day. Thee were two oscillating engines, connected by two UV joints to a gearbox each, then from the gearbox two more UV joints to the shafts. A total of eight UV joints in one model! They were all metal though and, I must admit the whole thing ran very smoothly. I wish I’d got a picture!

Dave Reed.

Dave Reed.