Hi Colin,

First of all thanks to Banjoman for the mention of my methods for planking. Now I know you (Colin) has access to all these but for those who don't and may be interested here's a short summary of perhaps the easiest way to do this type of planking.

Firstly, nearly every single hardwood out there will bend easily with this method, so get the actual wood you want to replicate and if you have terrible trouble, I'm sure I can find you some bits (I have tons of the stuff)

Teak and mahogany etc will make a lovely deck, so here goes. Cut a piece of chosen hardwood, or lime or whatever into 3mm strips about 25mm or so wide. I use artists black card (Black right through) and cut this into the same size strips as well. You need enough so that when they are all put side by side they cover the width of the are to be covered.

Take a template of the decks outside curve and transfer it to a chunk of 4 x 2 or bigger softwood a bit longer than the deck. Cut this down the line so you have two chunky pieces for the clamp. It also helps if it is a couple of inches longer than your decks.

Cover the softwood clamp with strips of polythene bag, use a staple gun but not on the clamp faces. This stops it all sticking to the clamp.

Get every 'G' cramp you've got ready, cover your flat work area with polythene and then steam all the hardwood in a steamer (Wickes Wallpaper stripper and a bit of pipe) or block off a bit of down pipe and fill with boiling water and stand up with the wood strips in for an hour.

Wear latex gloves. Start to layer one piece of hardwood and one piece of coloured card into the clamp using either Polyurethane wood glue (Gorilla) or Aliphatic Resin Glue, Layer these up (a cut down radiator roller works well here) till you have enough to cover the width of the deck. You need to work quickly!. The Gorilla glue will start to foam in contact with moisture in about 10 minutes!!!

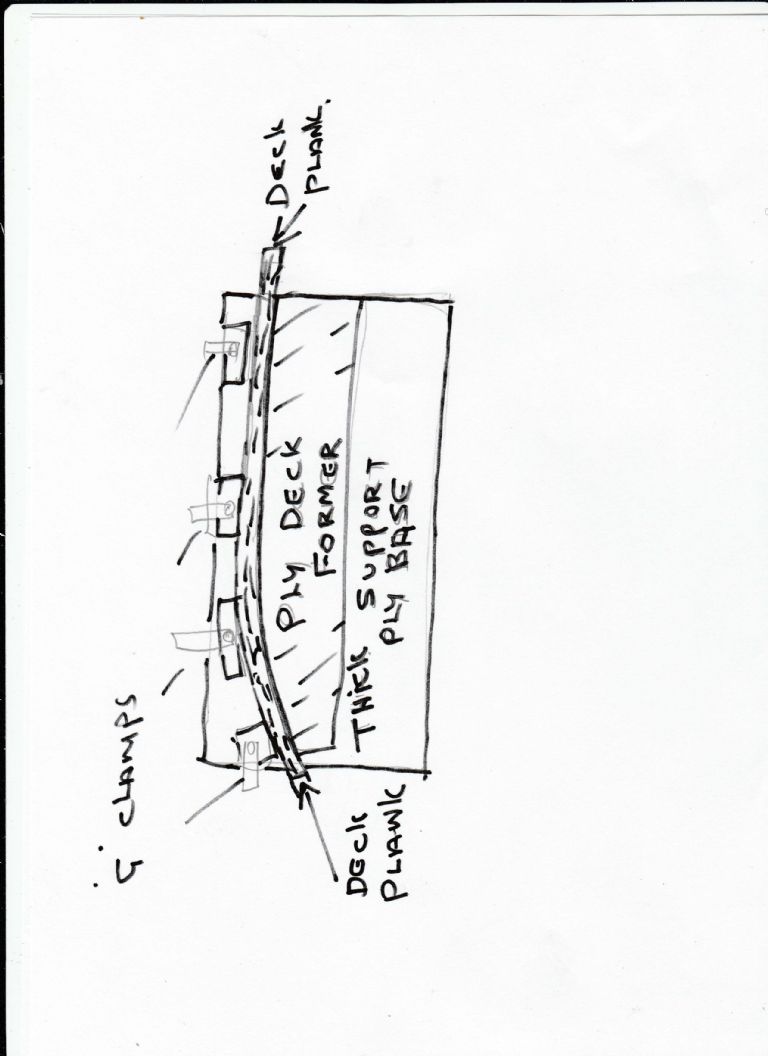

Place the second half of the clamp on top and lay it on its side. Start clamping the strips into a curve, pushing them down level as you go. You can't have too many clamps here, so no gaps hopefully. Clamp both sides really tight to stop it sliding and slipping.(Use a spanner if you have to)

Leave it all to dry for at least overnight.. A warm area is best as well.

Once dry, remove the clamps and you should have a curved lamination of wood and card. Trim off excess glue on one side to get a flat surface. Use a piece of white melamine to increase the height of your fence, hopefully on a bandsaw. Set cut width to about 2mm and slice the curved block across the laminations as many times as you can.

You should get enough good strips to choose from plus fill in pieces for the fore and stern decks. Glue down in place with weights till stuck and sand them smooth afterwards on the top only. Finish to taste with clear.

Different coloured card can be used for dark or light caulking depending on how old the original ship was.

Do deck capping strips after sanding the outside edges to overlap the deck to hull joint.

Hope this is easy to understand. PM me if you need wood or more into.

Cheers………..Ron. PS. Look at Banjomans links above.